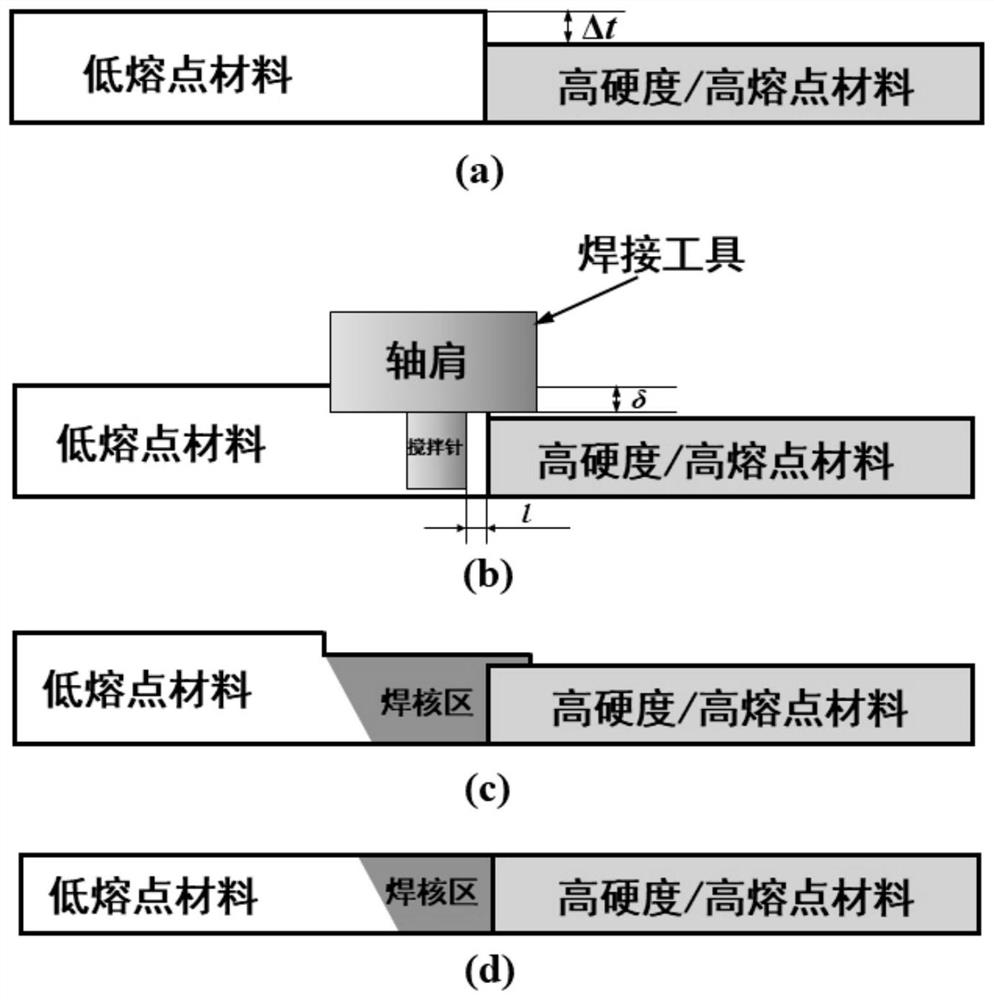

Differential-thickness-method friction stir welding process for realizing dissimilar material connection

A technology of friction stirring and dissimilar materials, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of low industrial practical applicability, low service performance of joints, poor welding quality, etc., and achieve wide industrial applications Prospect, elimination of premature formation of fatigue cracks, effect of improving weld formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

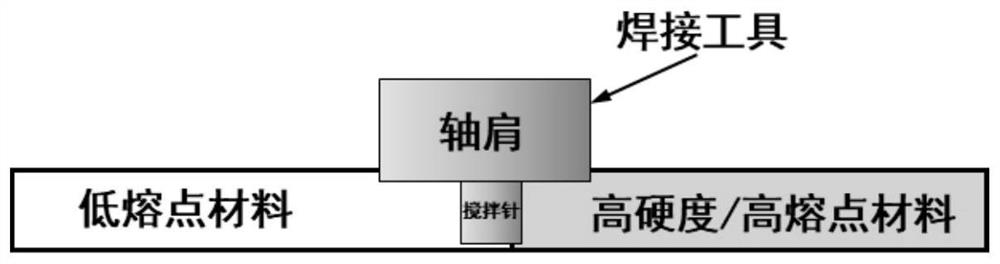

Method used

Image

Examples

Embodiment 1

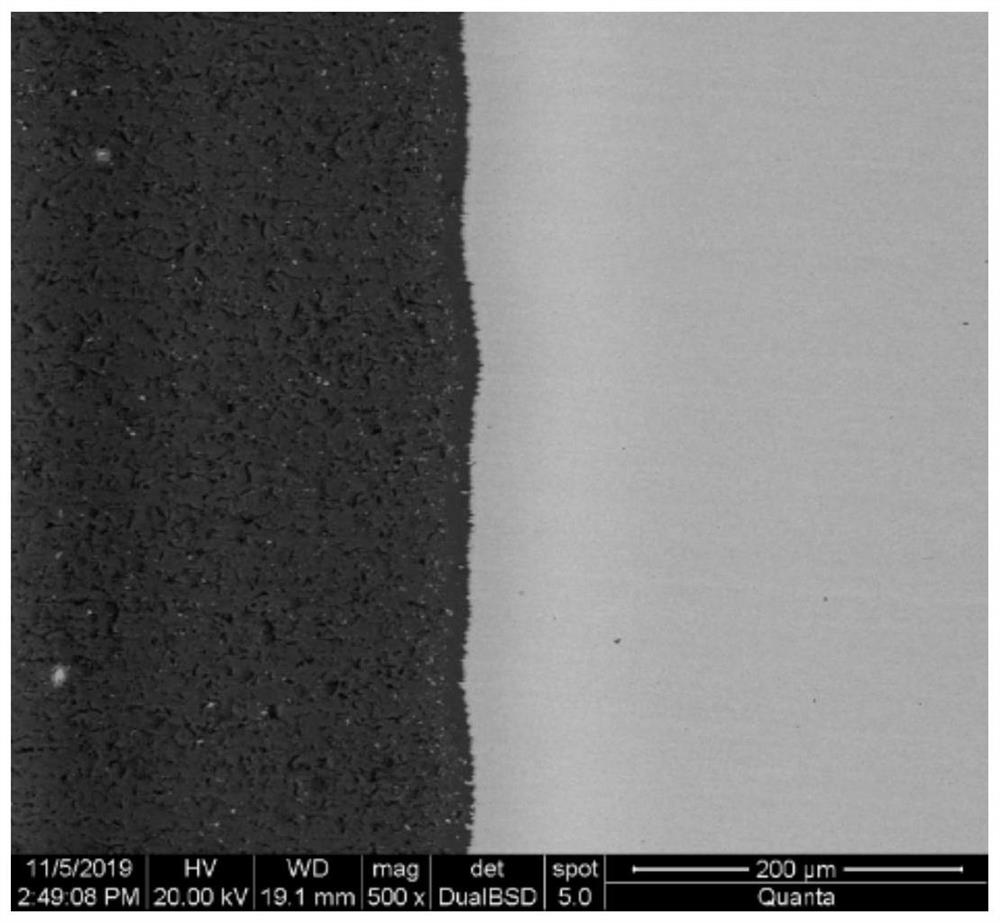

[0034] Use 5.6mm thick 1060 pure aluminum rolling plate with tensile strength of 120MPa and 5mm thick low carbon steel Q345 with tensile strength of 520MPa. The welding tool is made of H13 steel material, the diameter of the shoulder is 22 mm, the stirring needle is a cylindrical threaded needle, the diameter is 6 mm, and the length of the needle is 5 mm. During the welding process, the distance between the edge of the stirring needle and the low carbon steel is 0 mm. A reduction of 0.5 mm (shoulder 0.1 mm above the mild steel) and welding parameters of 1000 rpm of the welding tool and a travel speed of 100 mm / min resulted in defect-free welded joints. Microstructure observation shows that the interface is relatively straight and well bonded, and no large-sized steel particles appear in the weld nugget area ( image 3 ). Tensile tests at room temperature showed that the fracture of the joint was in the heat-affected zone on the aluminum side, and the tensile strength was 100 ...

Embodiment 2

[0044] Use 20.2mm thick 1060 pure aluminum plate with tensile strength of 110MPa and 20mm thick low carbon steel Q345 plate with tensile strength of 520MPa. The welding tool is made of H13 steel material, the diameter of the shoulder is 30mm, the stirring needle is a cylindrical threaded needle, the diameter is 14mm, and the length of the needle is 20mm. During the welding process, the edge of the stirring needle is 0.3mm away from the low carbon steel, refer to the shoulder of the aluminum plate A reduction of 0.2 mm (shoulder 0.1 mm above the mild steel) and welding parameters of 800 rpm of the welding tool and a travel speed of 50 mm / min resulted in defect-free welded joints. Microstructure observation shows that the interface is relatively straight, and no large-sized steel particles appear in the weld nugget area. The tensile test at room temperature showed that the fracture of the joint was in the heat-affected zone on the aluminum side, and the tensile strength was 95MP...

Embodiment 3

[0048] Using 2 mm thick 7075-T651 aluminum alloy with a tensile strength of 575 MPa and 1.8 mm thick zirconium-based amorphous (Zr 55 Cu 30 Al 10 Ni 5 )plate. The welding tool is made of M42 steel material, the diameter of the shoulder is 18mm, the stirring needle is a cylindrical threaded needle, the diameter is 4mm, and the length of the needle is 1.8mm. During the welding process, the edge of the stirring needle is 0.3mm away from the low carbon steel, referring to the shoulder of the aluminum plate A reduction of 0.1 mm (shoulders 0.1 mm above the amorphous sheet) and welding parameters of 2000 rpm of the welding tool and a travel speed of 200 mm / min resulted in defect-free welded joints. Microstructure observation shows that the interface is relatively straight, and no amorphous particles appear in the weld nugget area. The tensile test at room temperature showed that the fracture of the joint was in the heat-affected zone on the aluminum side, and the tensile strengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com