Novel flexible vehicle body assembly machine system

A technology for assembling machines and car bodies, applied in auxiliary devices, vehicle parts, transportation and packaging, etc., can solve the problems of long processing time, low efficiency, high risk, etc., to reduce labor intensity, reduce operators, and reduce flexibility. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

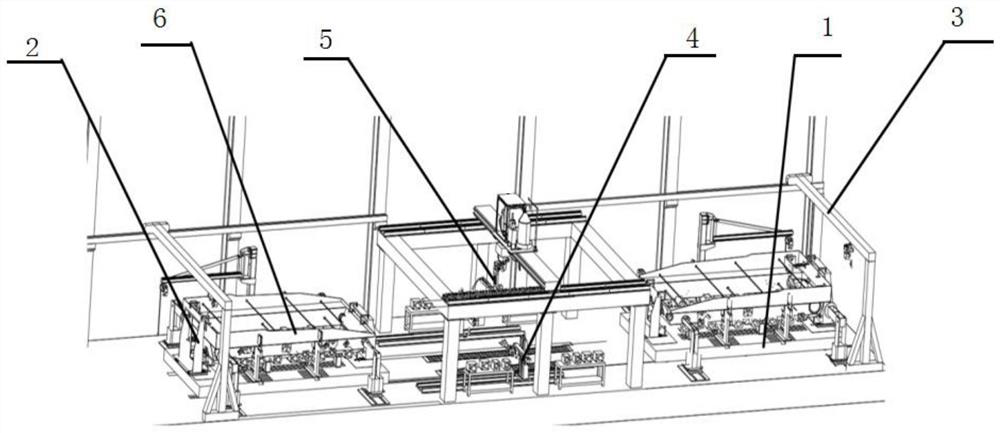

[0039] Such as figure 1 As shown, a new type of flexible car body assembly machine system, which includes a carrier platform 1, car body assembly tooling 2, auxiliary device 3, numerical control assembly machine 4 and welding robot 5;

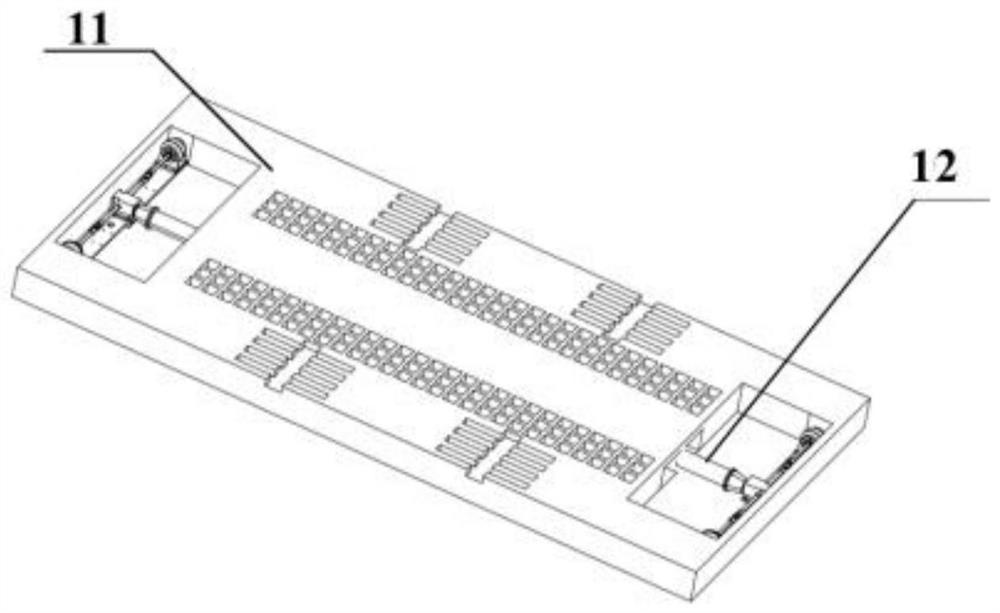

[0040] The carrier platform 1 above is as figure 2 As shown, the bottom surface is as image 3 As shown, it includes a cast iron platform 11, a driving device 12, a carrying rail and a platform pulley block 13; the platform pulley block 13 is arranged below the cast iron platform 11, and the driving device 12 is used to drive the platform pulley block 13 on the platform rail move;

[0041] In some embodiments, the platform pulley set 13 adopts a motor-driven wheel set and a low-voltage slide wire to take power, so as to realize the forward and backward movement of the carrying platform 1 on the guide rail;

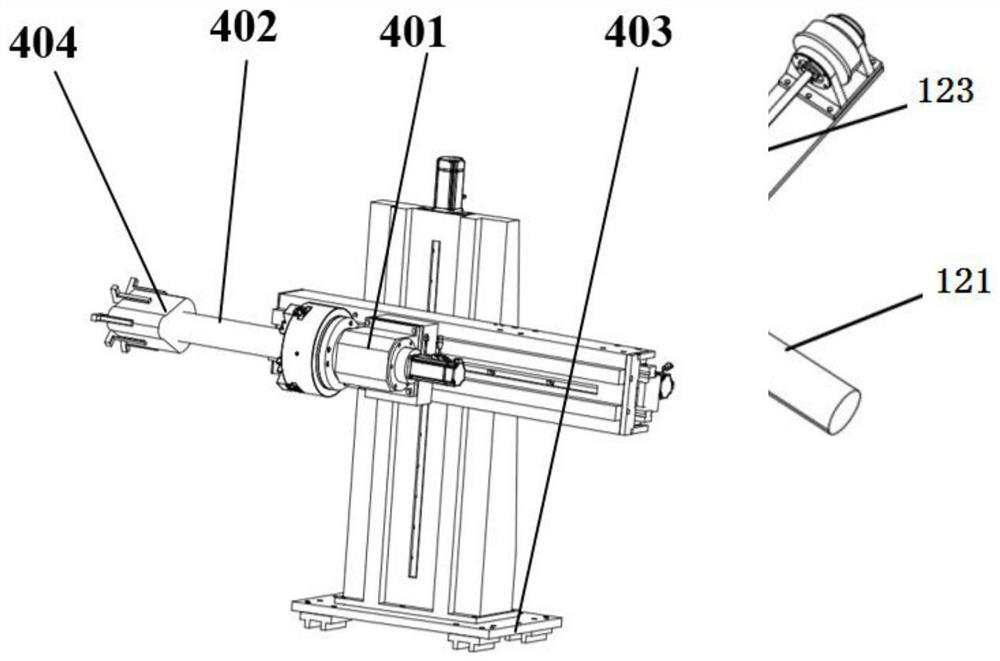

[0042] The ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com