Flexible composite material with high electromagnetic shielding performance and preparation method thereof

A composite material, electromagnetic shielding technology, used in magnetic field/electric field shielding, conductive adhesives, chemical instruments and methods, etc., can solve the problems of strong anisotropy, low electromagnetic shielding efficiency, etc. Electromagnetic shielding effectiveness and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of the flexible composite material with high electromagnetic shielding performance includes the following steps:

[0040] Step 1: Add the polymer into the solvent at a mass ratio of 1:(10~30), under the temperature condition of 20℃~60℃, stir magnetically at a stirring rate of 100r / min~400r / min for 12h~48h, dissolving the polymer in the solvent to obtain a polymer solution;

[0041] The polymer is a thermoplastic elastomer, and the thermoplastic elastomer includes: hydrogenated styrene-butadiene block copolymer (SEBS), styrene-butadiene-styrene block copolymer (SBS), polyacrylate, polyester , any one of EPDM rubber, nitrile rubber and butyl rubber;

[0042] The solvent includes any one of dimethylformamide, dimethylacetamide, acetone, and butanone.

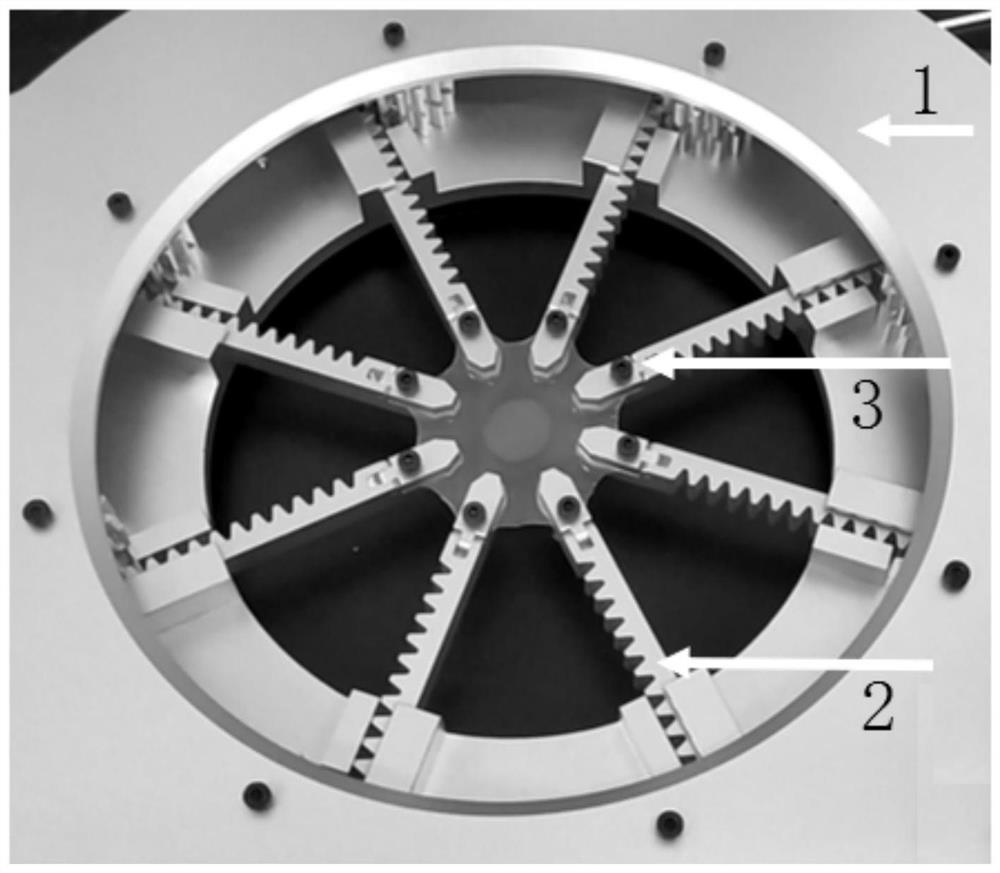

[0043] Step 2: adding the liquid metal to the polymer solution at a volume ratio of (1~5):(5~9), the sum of the volume percentages of the liquid metal and the polymer solution is 100%, and at 20 ℃~40...

Embodiment 1

[0058] The preparation method of the flexible composite material with high electromagnetic shielding performance includes the following steps:

[0059] (1) Add 30 g of hydrogenated styrene-butadiene block copolymer to 600 g of dimethylformamide, and magnetically stir at a stirring rate of 250 r / min for 30 h at a temperature of 40° C. to obtain a polymer solution.

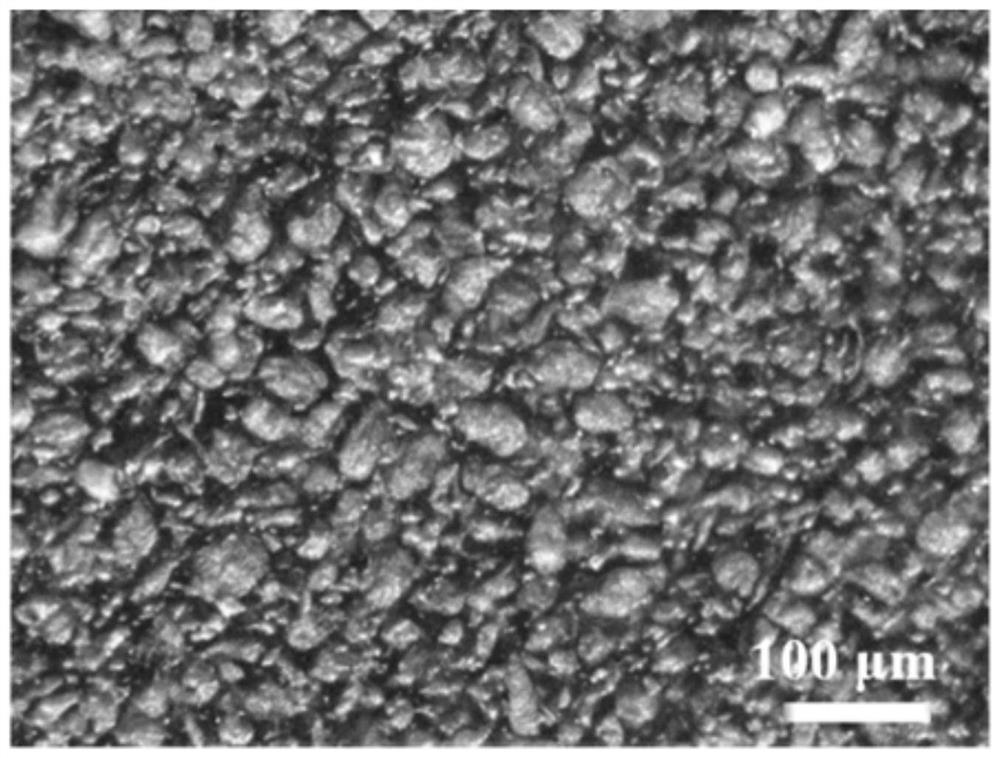

[0060] (2) Add gallium indium eutectic alloy (EGaIn) liquid metal with a melting point of 15°C into the polymer solution at a volume ratio of 3:7, and mechanically stir at a stirring rate of 125 r / min at a temperature of 30°C 7h, a mixed emulsion was obtained.

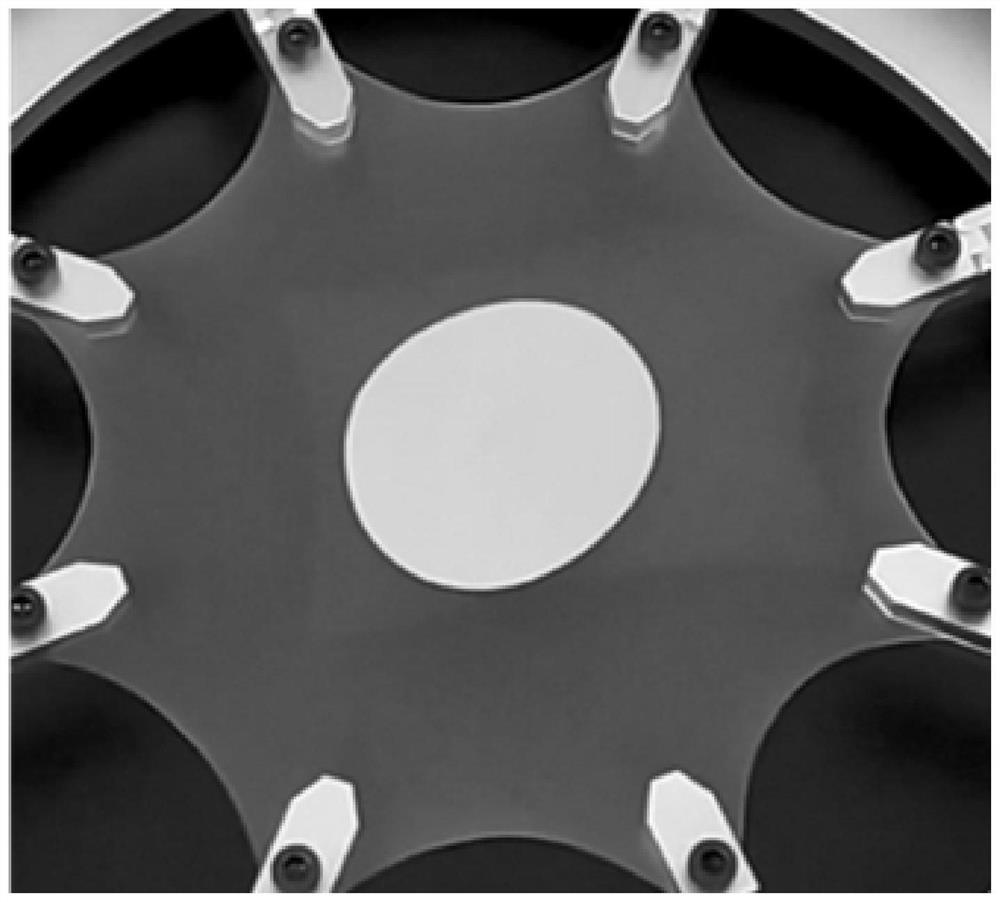

[0061] (3) Under the condition of room temperature, the mixed emulsion was cast on the PET film tape substrate, the movement speed of the push rod during the casting process was 1.25mm / s, and the thickness of the cast material was controlled by adjusting the height of the scraper of the casting machine. 1.75mm, transfer the substrate carrying the cast mater...

Embodiment 2

[0069] The preparation method of the flexible composite material with high electromagnetic shielding performance includes the following steps:

[0070] (1) 40 g of polyacrylate was added to 400 g of acetone, and magnetically stirred at a stirring rate of 100 r / min for 12 h at a temperature of 20° C. to obtain a polymer solution.

[0071] (2) Add the gallium indium eutectic alloy (EGaIn) liquid metal with a melting point of 15°C into the polymer solution at a volume ratio of 1:9, and mechanically stir at a stirring rate of 50r / min at a temperature of 20°C 2h, a mixed emulsion was obtained.

[0072] (3) Under the condition of room temperature, the mixed emulsion is cast on the glass substrate, the movement speed of the push rod is 0.5mm / s during the casting process, the thickness of the cast material is controlled to be 0.5mm, and the cast material is loaded with the cast material. The substrate was transferred to a vacuum oven, vacuumed, and then vacuum-dried at a temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com