Hydroxyl nickel chloride nano material and preparation method thereof

A technology of nickel hydroxychloride and nanomaterials, applied in nickel halide, nanotechnology and other directions, to achieve the effects of short reaction time, simple operation and easy reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Using nickel chloride hexahydrate powder and nickel hydroxide powder as raw materials, first weigh 0.2853g NiCl 2 6H2O crystalline powder (1.2mmol), pour it into a mortar and grind for 15 minutes, then weigh 0.0927g Ni(OH) 2 (1mmol) into the mortar, fully mixed and ground for 40 minutes, put the ground mixture into the reaction kettle, and reacted for 5 hours at a reaction temperature of 170°C. After the reaction was completed, cool to room temperature and continue grinding the product for 15 minutes. , to obtain a light green powder (NiOHCl) sample.

[0024] This embodiment is the best embodiment.

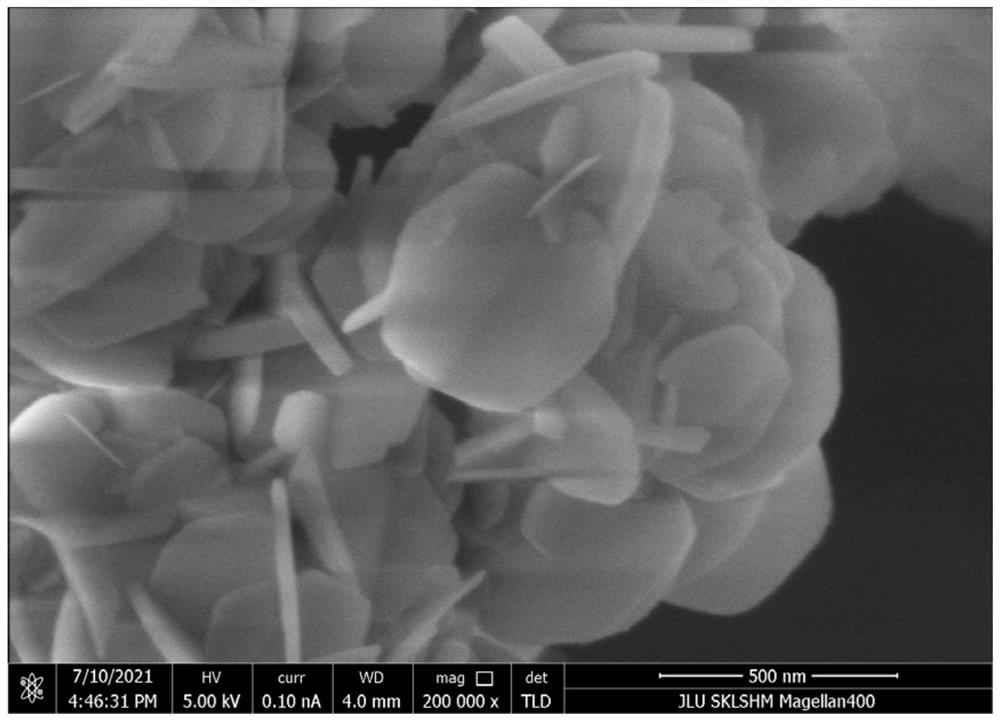

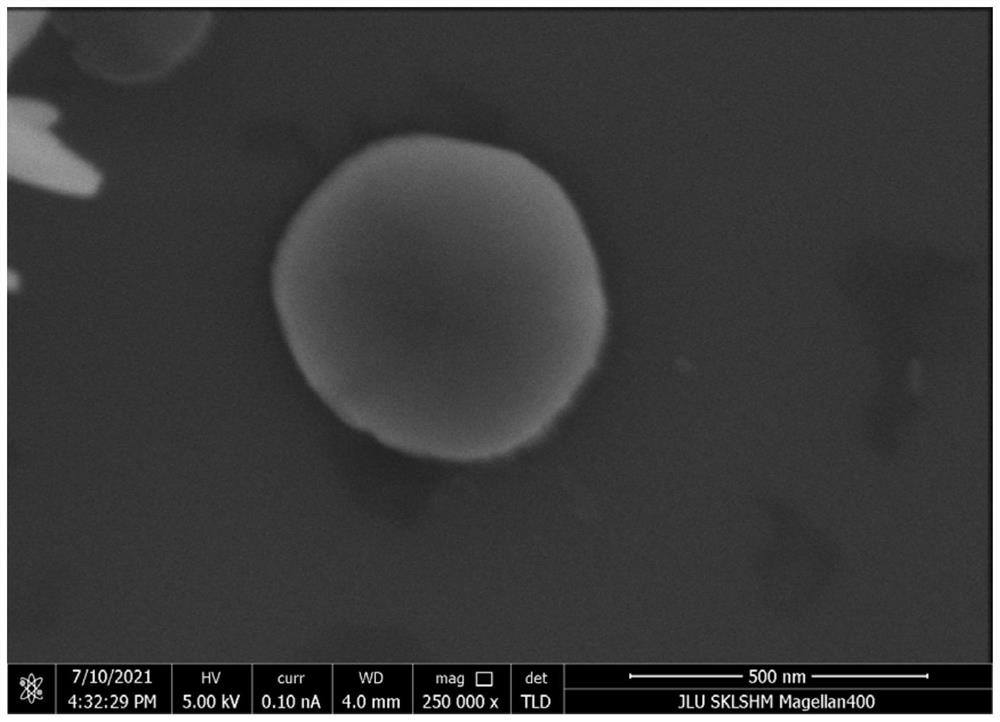

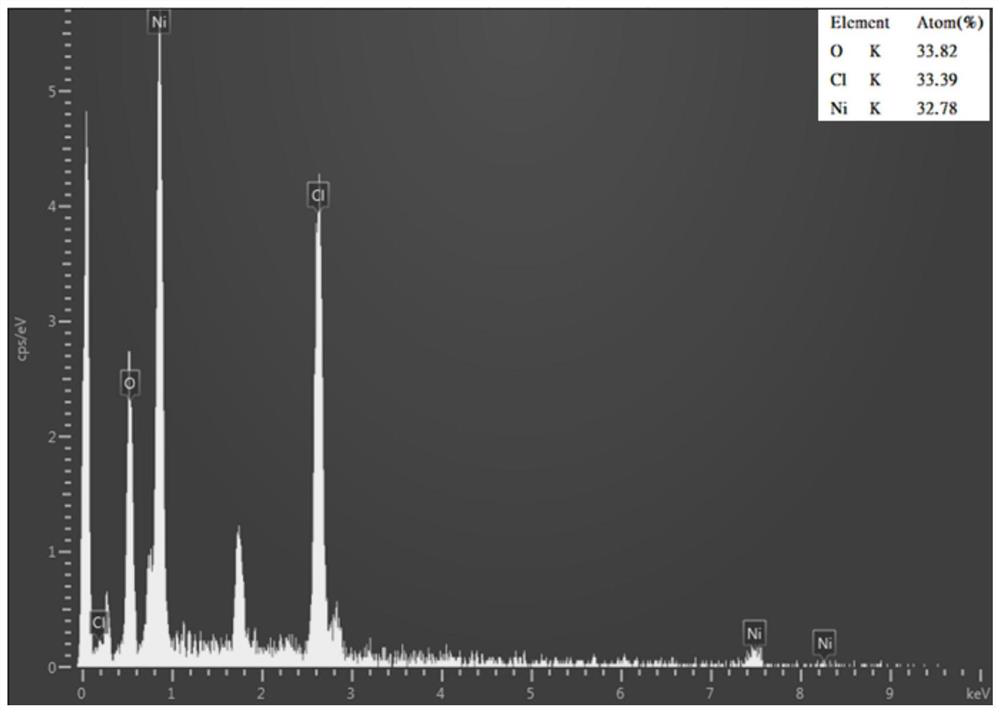

[0025] figure 1 and figure 2 The SEM image of the NiOHCl nanomaterial prepared under the above conditions is given. It can be seen that the NiOHCl product is in the shape of nanosheets, the thickness of the nanosheets is 6-50nm, the side length is 20-520nm, and the nanosheets have a straight and regular surface. image 3 The EDS spectrum of the nanosheets prepared unde...

Embodiment 2

[0027] Using nickel chloride hexahydrate powder and nickel hydroxide powder as raw materials, first weigh 0.2853g NiCl 2 6H2O crystalline powder, pour it into a mortar and grind for 15 minutes, then weigh 0.0927g Ni(OH) 2 Add it into a mortar, mix thoroughly and grind for 40 minutes, put the ground mixture into a reaction kettle, and react for 5 hours at a reaction temperature of 150°C. After the reaction is completed, cool to room temperature, and continue grinding the product for 15 minutes to obtain a shallow Green powder (NiOHCl) sample.

[0028] Figure 5 The SEM images of the NiOHCl nanomaterials prepared under the above conditions are given. It can be seen that the material is still in the form of flakes, the sample has obvious graininess, and the surface of the sample is not smooth.

Embodiment 3

[0030] Using nickel chloride hexahydrate powder and nickel hydroxide powder as raw materials, first weigh 0.2853g NiCl 2 6H2O crystalline powder, pour it into a mortar and grind for 15 minutes, then weigh 0.0927g Ni(OH) 2 Add it into a mortar, mix thoroughly and grind for 40 minutes, put the ground mixture into a reaction kettle, and react for 5 hours at a reaction temperature of 130°C. After the reaction is completed, cool to room temperature, and continue grinding the product for 15 minutes to obtain shallow Green powder (NiOHCl).

[0031] Image 6 The SEM image of the NiOHCl nanomaterial prepared under the above conditions is given, it can be seen that the material is still in the form of a sheet, some nanosheets become thicker, and the surface of the sample is not smooth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com