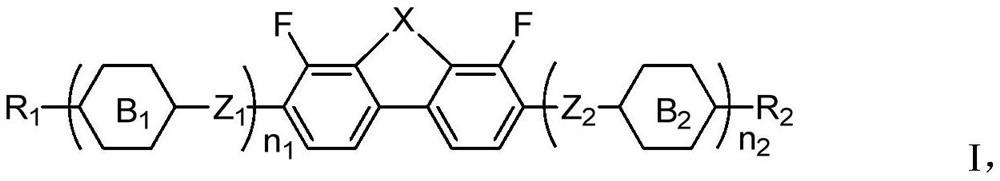

Liquid crystal compound and liquid crystal composition containing same, and liquid crystal display device

A technology of liquid crystal compounds and compounds, applied in the direction of liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems of unfavorable low threshold voltage temperature range of liquid crystal display devices, small dielectric anisotropy, small clearing point, etc., to achieve Effect of wide nematic temperature range, short response time, and good contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

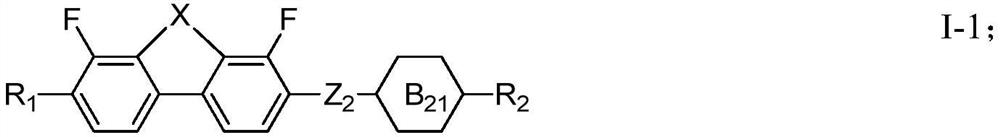

Embodiment 1

[0235] The synthetic route of compound I-1-3-1 is as follows:

[0236]

[0237] Step 1. Preparation of compounds of formula B-3

[0238] Add 110g of the compound of formula B-1 ((4-ethoxy-2,3-difluorophenyl)boronic acid)) and 100g of the compound of formula B-2 (2-bromo-6-fluorophenol ) and 110g of sodium carbonate, and fully dissolved with 1.2L of a mixed solvent consisting of toluene, ethanol and water (the volume ratio of toluene, ethanol and water is 2:1:1). Under the condition of nitrogen protection, 1.8g of 4-3-Pd (tetraphenylphosphine palladium) was added, and the reaction was refluxed for 6h. The reaction solution was cooled, 300 mL of water was added for liquid separation, the aqueous phase was extracted with toluene, the organic phases were combined, and the organic phase was washed with saturated brine to pH=7, dried, concentrated, and mixed solvent (petroleum ether) composed of petroleum ether and toluene The volume ratio to toluene is 24:1) and recrystallize...

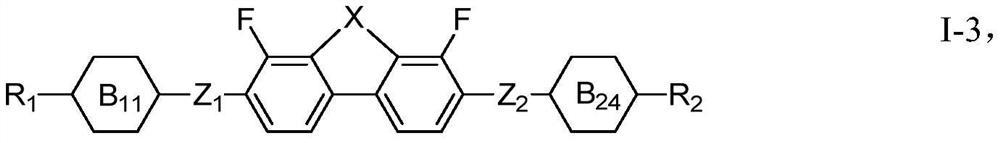

Embodiment 2

[0250] The synthetic routes of compounds I-3-9-1 and I-3-5-1 are as follows:

[0251]

[0252] Step 1. Preparation of compounds of formula B-8

[0253] In a 2L reaction flask, add 80g of the compound of formula B-7 ((2,3-difluoro-4'-propyl-[1,1'-biphenyl]-4-yl)boronic acid), 52.71g of formula B -2 compound (2-bromo-6-fluorophenol) and 86g of sodium carbonate, and use 1.2L of mixed solvent consisting of toluene, ethanol and water (the volume ratio of toluene, ethanol and water is 2:1:1) dissolve. Under the condition of nitrogen protection, 1.8g of 4-3-Pd (tetraphenylphosphine palladium) was added, and the reaction was refluxed for 6h. The reaction solution was cooled, 300mL of water was added, the aqueous phase was extracted with toluene, the organic phases were combined, the organic phase was washed with saturated brine to pH=7, dried, concentrated, and a mixed solvent composed of petroleum ether and toluene (petroleum ether and toluene The volume ratio is 24:1) to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com