Preparation method of a modification-free and recyclable photothermally driven self-healing epoxy anti-corrosion coating material

An anti-corrosion coating and self-repairing technology, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as complicated, large influence on coating mechanical properties, expensive chemical processes, etc., and achieve excellent barrier ability and response Fast and Controllable Effects

Active Publication Date: 2022-05-31

SUN YAT SEN UNIV

View PDF12 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method has no direct effect on the "repairability" and "recyclability" of the coating resin itself, and has a greater impact on the mechanical properties of the coating

The second is the "intrinsic type", which relies on reversible dynamic chemical reactions (acylhydrazone bonds, disulfide bonds, Diels-Alder reactions) to achieve polymer self-healing, and this process often requires pre-modified epoxy monomers. sex, involving complex and expensive chemical processes

However, the above-mentioned technologies only realize the damage repair ability of epoxy coatings, but cannot solve the problem of "recyclability" of epoxy coatings.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

Login to View More

Abstract

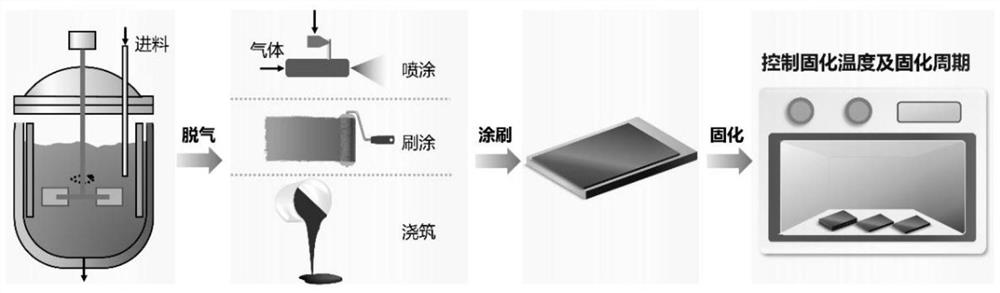

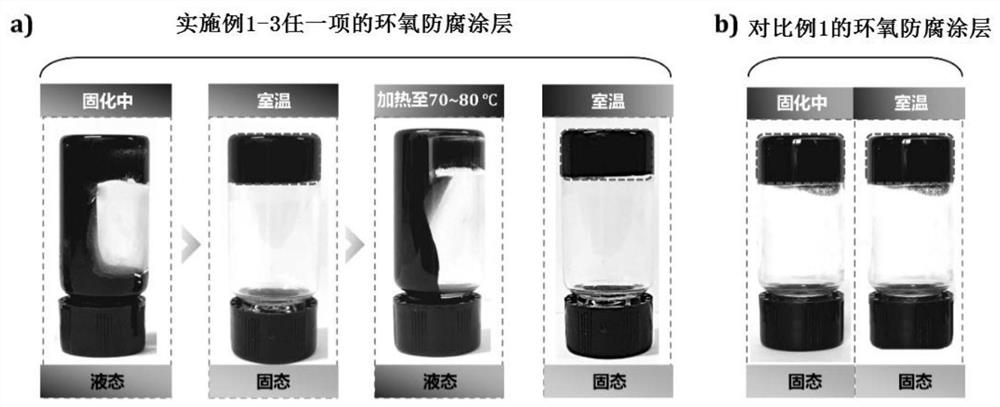

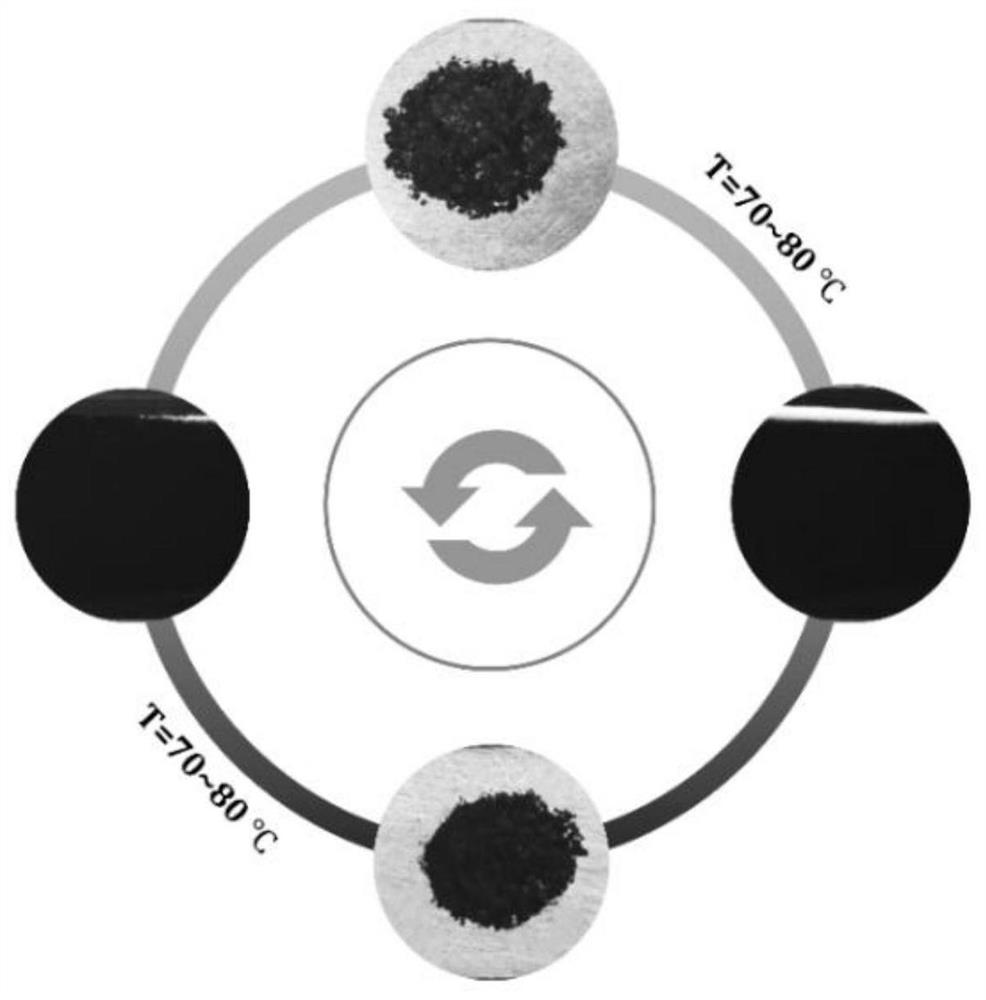

The invention belongs to the technical field of epoxy anti-corrosion coatings, and in particular relates to a preparation method of a photo-thermal driven self-repairing epoxy anti-corrosion coating material that is free from modification and recyclable. Acids are used as curing agents, and carbon materials are introduced as photothermal fillers to construct a catalyst-free epoxy-acid anhydride curing system, which is finally prepared by curing at a curing temperature of 110℃-130℃ for 4h-12h. The preparation process does not involve any organic solvents, no volatile organic compounds are generated, and is environmentally friendly; the required raw materials are all commercial existing products, and the preparation process does not require any chemical modification, and can be coated in various ways; the repair process of the coating is mainly based on Heating causes the material to undergo a solid-liquid phase transition, which has the advantages of fast and controllable response, and can be triggered in various ways.

Description

Fabrication of a modification-free and recyclable photothermal driven self-healing epoxy anticorrosion coating material backup method technical field The invention belongs to the technical field of epoxy anti-corrosion coatings, be specifically related to a kind of photothermal drive self-repair that is free from modification and recyclable Preparation method of composite epoxy anti-corrosion coating material. Background technique As a typical thermosetting resin, epoxy resin has excellent thermal stability, solvent resistance and adhesion. force, is widely used in the field of coating. Since epoxy resins are thermoplastic linear structural monomers before curing, their application The value is often realized by cross-linking with the curing agent and forming an infusible and insoluble cross-linked network, which also leads to its Non-recyclability, resulting in a great waste of materials. [0003] Epoxy coating, as one of the most effective means for preventing a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09D163/02C09D7/61C09D5/08

CPCC09D163/00C09D7/61C09D5/08C08G59/4215C08G2150/90C08K2201/011C08K3/04C08K3/041C08K3/042C08G59/42

Inventor 李伟华申婷赵书瑞

Owner SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com