A kind of method for preparing nano-titanium dioxide by steaming at low temperature

A technology of nano-titanium dioxide and water steaming, which is applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of unenvironmental protection, human health, complicated preparation process, unfavorable mass production, etc., to reduce fire hazards, High catalytic activity and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Under the state of vigorous stirring in a water bath at normal pressure of 30°C, the mixed solution of tetrabutyl titanate and glacial acetic acid was added dropwise to the aqueous acetic acid solution, and the pH of the aqueous solution was controlled to be 2-3. The molar ratio of tetrabutyl titanate, deionized water, chelating agent and catalyst is 1:200:5:3. After the dropwise addition was completed, stirring was continued for 2 h. Static to aging for 48h, TiO with blue light is obtained 2 transparent sol. Then the aged nano-TiO 2 The sol was put into a glass watch glass, and dried in a steam system at 100°C under normal pressure for 8 hours to obtain nano-TiO 2 Powder.

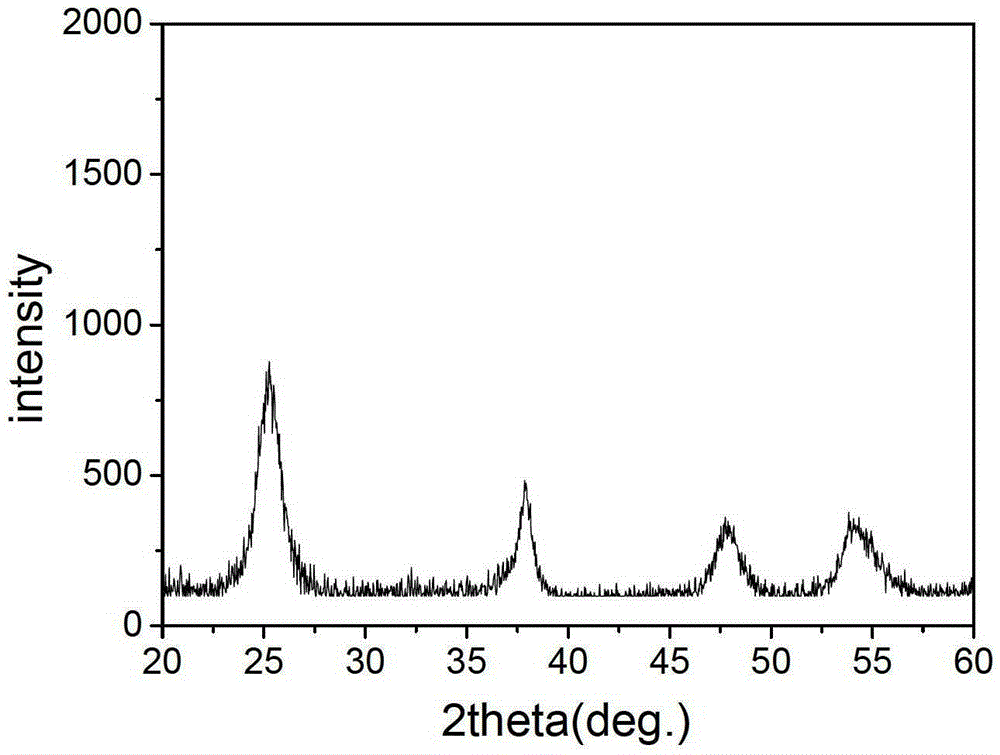

[0041] Its XRD patterns and performance indicators are shown in image 3 and Table 2.

[0042] Table 2 TiO prepared under normal pressure water steaming system 2 Powder properties

[0043]

Embodiment 3

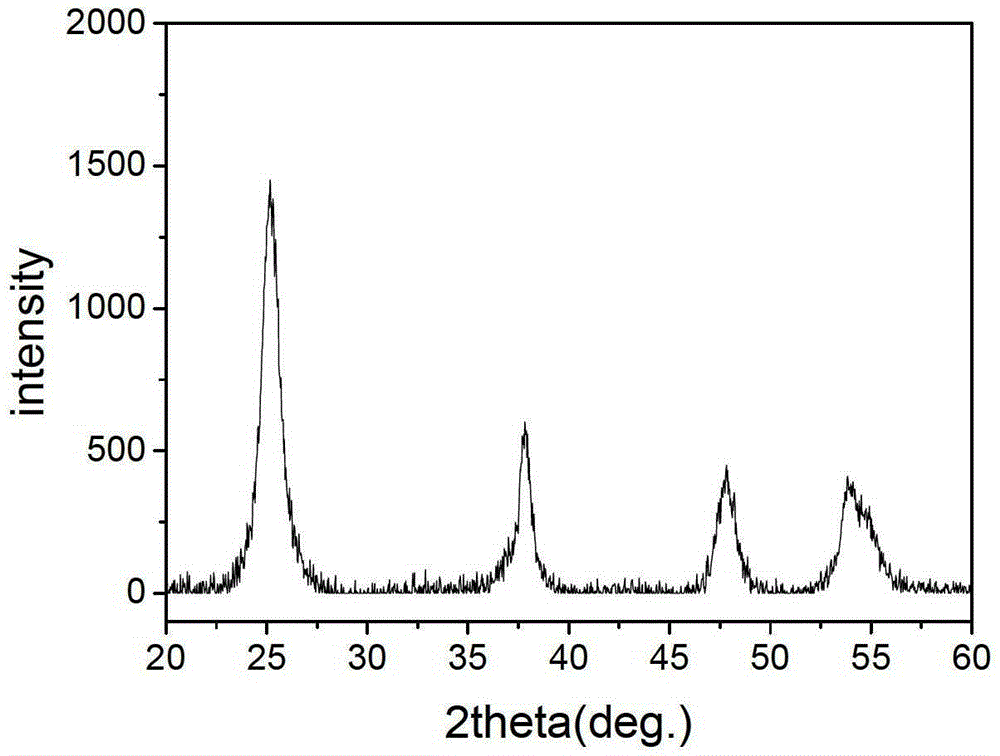

[0045] Under the state of vigorous stirring in a water bath at normal pressure of 30°C, the mixed solution of tetrabutyl titanate and glacial acetic acid was added dropwise to the aqueous acetic acid solution, and the pH of the aqueous solution was controlled to be 2-3. The molar ratio of tetrabutyl titanate, deionized water, chelating agent and catalyst is 1:190:5:5. After the dropwise addition was completed, stirring was continued for 2 h. Static to aging for 48h, TiO with blue light is obtained 2 transparent sol. Then the aged nano-TiO 2 The sol was put into a glass watch glass and dried in a steam system at 0.18MPa and 130°C for 6h to obtain TiO 2 Powder. Its XRD see Figure 4 , and the performance is shown in Table 3 below.

[0046] Table 3 TiO prepared under high pressure steam system 2 Powder properties

[0047]

[0048] It can be seen that the nano-TiO obtained by the high-pressure steam drying system 2 The powder has good photocatalytic activity, and the 5...

Embodiment 4

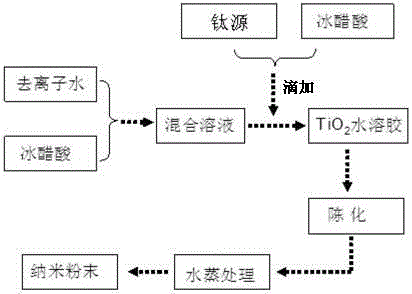

[0050] A method for preparing nano-titanium dioxide by steaming at low temperature, the process flow is as follows figure 1 shown, including the following steps:

[0051] (1) Mix tetrabutyl titanate and glacial acetic acid evenly to obtain a yellow solution.

[0052] (2) Mix deionized water and glacial acetic acid, pour it into a three-necked flask, put it in a constant temperature water bath at 30°C, and slowly add the yellow solution in step (1) to the aqueous acetic acid solution under stirring with an electric stirrer After dropping, continue to stir vigorously for 2 hours, and after aging for 48 hours, a transparent nano-TiO2 aqueous sol with blue light is obtained. The molar ratio of the tetrabutyl titanate, deionized water, chelating agent and catalyst is 1:200:5:3.

[0053] (3) Select the soft base material cotton fabric as the base material, immerse the aged nano-TiO 2 In the hydrosol, immerse in a water steaming system at normal pressure 100°C for 8 hours, wash an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com