Novel method for preparing metal cyanide nanoparticles

A nanoparticle and cyanide technology, which is applied in the field of preparation of metal cyanide nanoparticles, can solve the problems that no one has publicly reported the application of AuCN nanoparticles, and achieve the effect of controllable particle size and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

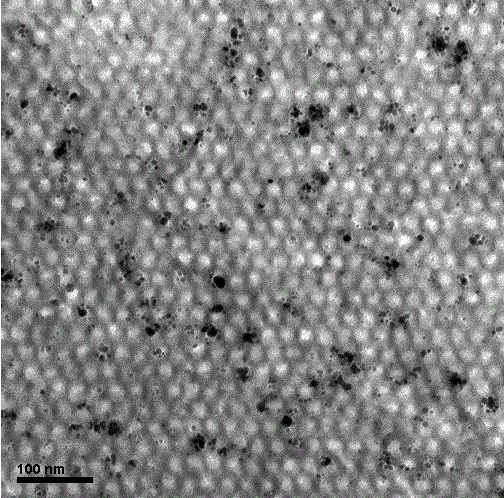

[0030] First, mix 10 mg nano-gold loaded mesoporous silica, 2 mL acetonitrile, and 100 μmol benzaldehyde, and stir; place the above suspension under a 350-watt mercury lamp, stir and illuminate, and the illumination time is 2 hours , the color of the solid gradually changed from red to green; the product was centrifuged and dried to obtain nano-gold cyanide-loaded mesoporous silica. figure 1 It is a transmission electron microscope photo of the nano-gold cyanide, from which it can be obtained that the product is nano-particles, uniformly dispersed, and the particle diameter is 10-30 nanometers.

Embodiment 2

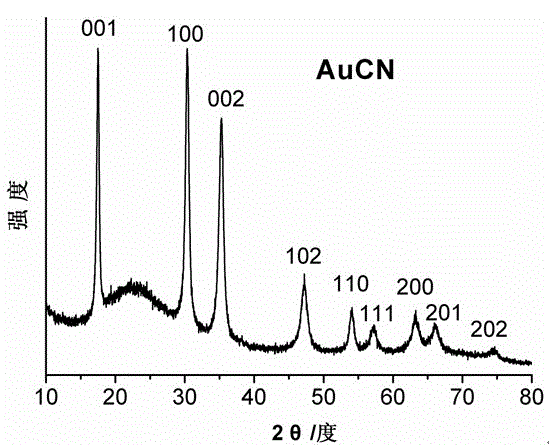

[0032] Mix 100 mg of supported gold nanoparticles, 4 mL of acetonitrile, and 200 μmol of benzyl alcohol together and stir; then place the above suspension under a 350-watt mercury lamp, stir and illuminate for 5 hours, and the color of the solid is as follows: The red color gradually changed to green; the product was centrifuged and dried to obtain loaded nano-gold cyanide. figure 2 It is the XRD pattern of this nano-gold cyanide, the product is pure gold cyanide, and its chemical formula is AuCN.

Embodiment 3

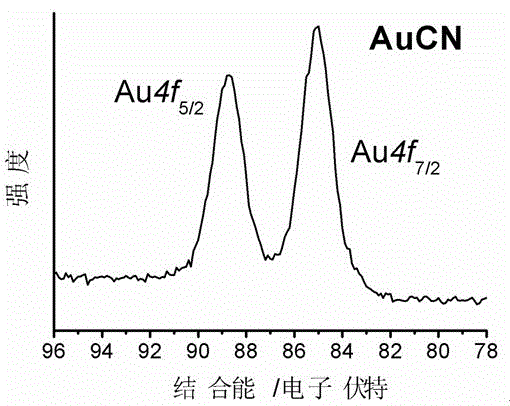

[0034] Mix 500 mg of supported gold nanoparticles, 5 mL of acetonitrile, and 500 μmol of hydrogen peroxide, and stir; then place the above suspension under a 350-watt mercury lamp, stir and illuminate for 10 hours, and the color of the solid changes from red to Gradually turn into green or even white; the product is centrifuged and dried to obtain loaded nano-gold cyanide. image 3 is the XPS spectrum of AuCN nanoparticles, showing Au4f 5 / 2 and Au4f 7 / 2 The peak position of corresponds to that of Au(I).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com