Corrosion-resistant high-strength aluminum alloy and preparation method thereof

An aluminum alloy and corrosion-resistant technology, which is applied in the field of corrosion-resistant high-strength aluminum alloy and its preparation, can solve the problems of insufficient tensile strength and corrosion resistance, difficulty in meeting high-quality requirements, etc., achieve excellent anti-corrosion performance, and improve resistance to exfoliation corrosion , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

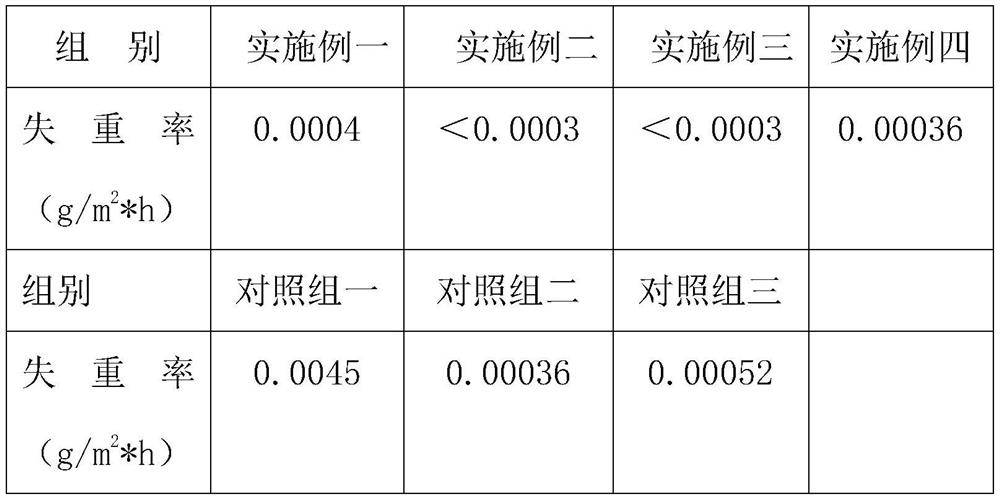

Examples

Embodiment 1

[0026] A corrosion-resistant high-strength aluminum alloy, comprising the following components in mass percentage: Mg0.65%, Fe 0.08%, Cr0.12%, Cu 1.35%, Zn 5.42%, Ti 0.08-%, Si 0.35%, Ni 0.03% , Sr 0.06%, Zr 0.05%, rare earth element 0.03%, impurity ≤ 0.12%, the balance is Al, and the rare earth element is composed of Sc and Yb mixed in equal proportions.

[0027] The preparation method of the above-mentioned corrosion-resistant high-strength aluminum alloy comprises the following steps:

[0028] S1. Weigh the corresponding proportion of raw materials, and add the prepared raw materials into the melting furnace for melting until a uniform melt is obtained. The temperature during melting is 720 °C and the melting time is 3.5 hours;

[0029] S2. Refining the melt obtained in S1 at a refining temperature of 800°C, introducing a mixed gas of nitrogen and argon, and adding a refining agent. After refining, perform slag removal and degassing treatment, and then smelt and cast it int...

Embodiment 2

[0034] A corrosion-resistant high-strength aluminum alloy, including the following components in mass percentage: Mg0.80%, Fe 0.10%, Cr0.13%, Cu 1.50%, Zn 5.85%, Ti 0.09%, Si0.45%, Ni 0.04% , Sr 0.08%, Zr 0.06%, rare earth element 0.05%, impurity ≤ 0.13%, the balance is Al, and the rare earth element is composed of Sc and Yb mixed in a ratio of 1:2.

[0035] A method for preparing a corrosion-resistant high-strength aluminum alloy, comprising the following steps:

[0036] S1. Weigh the corresponding proportion of raw materials, and add the prepared raw materials into the melting furnace for melting until a uniform melt is obtained. The temperature during melting is 730°C and the melting time is 3.0h;

[0037] S2. Refining the melt obtained in S1 at a refining temperature of 820°C, introducing a mixed gas of nitrogen and argon, and adding a refining agent. After refining, perform slag removal and degassing, and then smelt and cast it into an aluminum alloy Ingot;

[0038] S3....

Embodiment 3

[0042]A corrosion-resistant high-strength aluminum alloy, including the following components in mass percentage: Mg1.65%, Fe0.15%, Cr0.16%, Cu2.25%, Zn7.12%, Ti0.13%, Si0.75%, Ni0.05 %, Sr 0.10%, Zr 0.08%, rare earth elements 0.03-0.08%, impurities ≤ 0.14%, the balance is Al, and the rare earth elements are composed of Sc and La mixed in equal proportions.

[0043] A method for preparing a corrosion-resistant high-strength aluminum alloy, comprising the following steps:

[0044] S1. Weigh the corresponding proportion of raw materials, and add the prepared raw materials into the melting furnace for melting until a uniform melt is obtained. The temperature during melting is 740°C and the melting time is 2.5 hours;

[0045] S2. Refining the melt obtained in S1 at a refining temperature of 840°C, introducing a mixed gas of nitrogen and argon, and adding a refining agent. After refining, perform slag removal and degassing, and then smelt and cast it into an aluminum alloy Ingot; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com