Combined type pre-reaming construction method suitable for stratum with rock hardness smaller than or equal to 30 Mpa

A construction method and a combined technology, which are applied to drilling equipment and methods, earthwork drilling, percussion drilling, etc., can solve the problems of lack of combined pre-expanding construction methods, many times of fastening of B-type tongs, The construction technology is not very mature and other problems, so as to achieve the effect of good hole formation, reduction of safety hazards and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

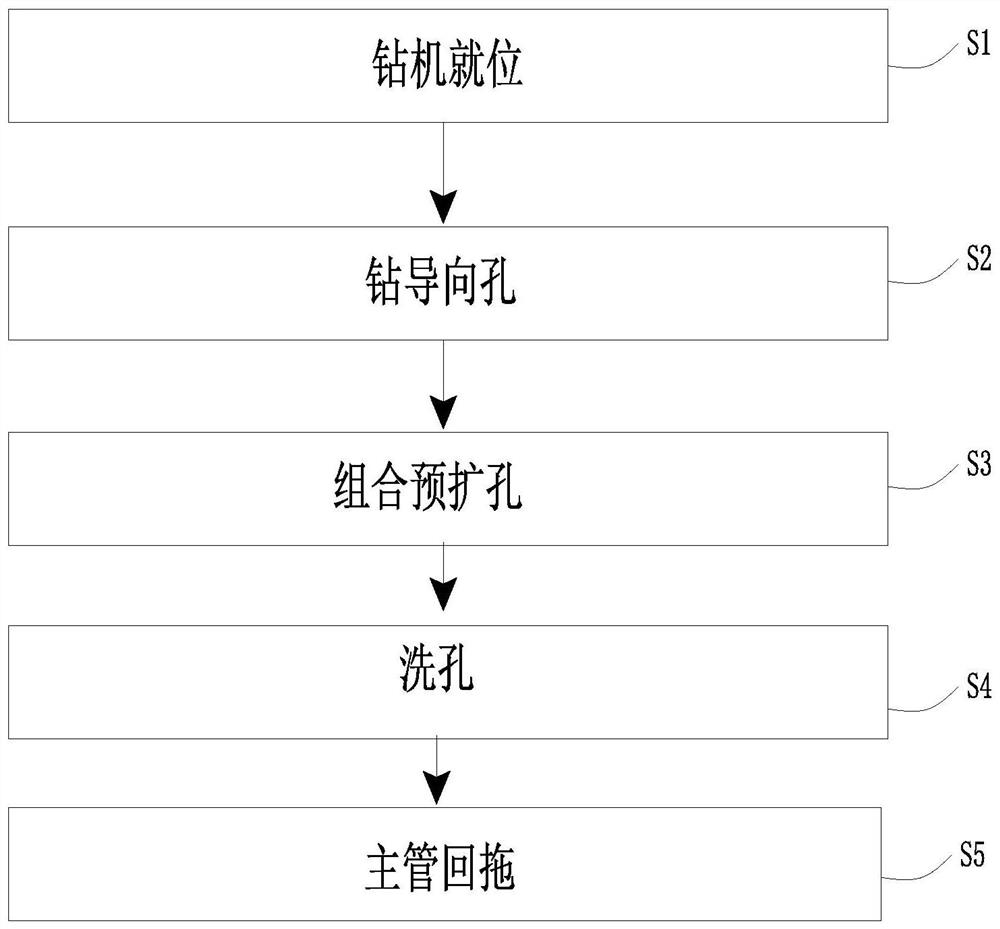

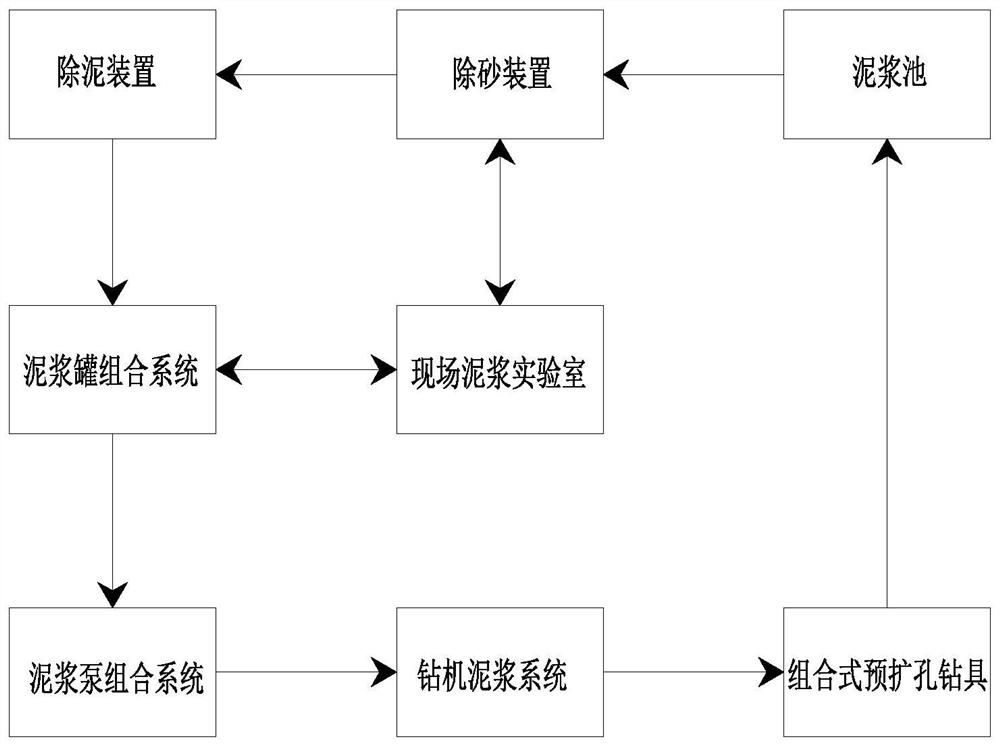

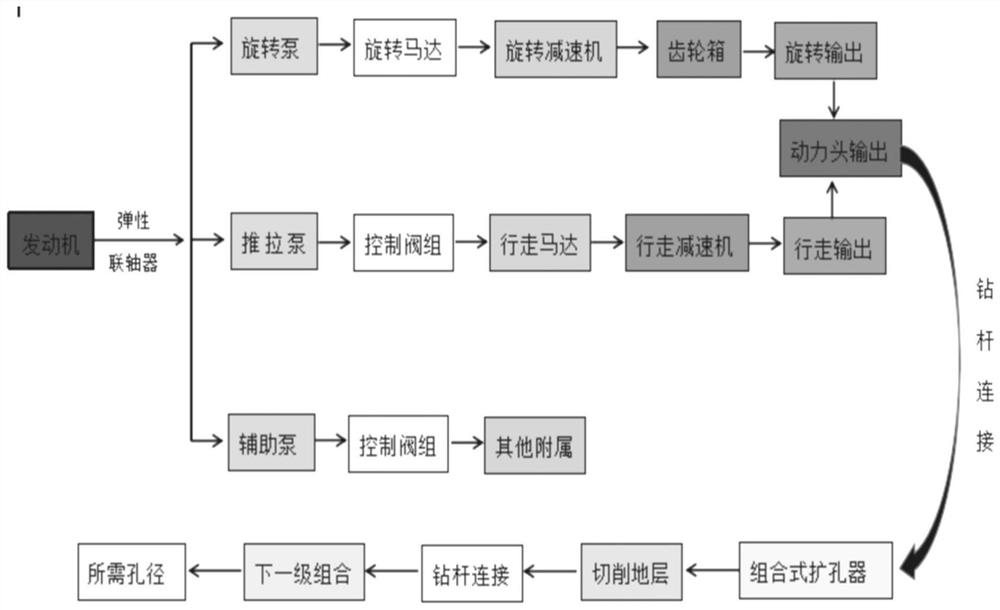

[0036] The present invention will be further described below in conjunction with the accompanying drawings, as shown in the accompanying drawings Figure 1 to Figure 3 As shown, taking the Gongqing River directional drilling project in the 2nd bid section of the Maoming-Yangjiang main line project of the western Guangdong natural gas main pipeline network as an example: the following steps are included,

[0037] S1: The drilling rig is in place;

[0038] 1.1 According to the actual situation of the construction stratum, the calculated pullback force is 1600KN, considering the safety factor of 2 to 3 times, the anchoring force of the ground anchor should be ≥ 3200KN.

[0039] 1.2 According to the coordinates of the entry point and exit point in the design drawings, determine the axis that the drilling rig traverses. The axis that the drilling rig traverses should be on the same line as the pipeline crossing axis or parallel to the pipeline crossing axis.

[0040] S2: drill pil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com