Equipment and method for measuring micropore leakage rate of injection glass container

A technology of glass containers and measuring equipment, which is applied in the field of measuring equipment for the micropore leakage of glass injection containers, which can solve the problem of shortening the sealing verification test cycle of glass injection containers, failing to determine the value of micropore size measurement tests for positive samples, and reducing testing costs and other issues, achieve important social benefits and commercial value, shorten the test cycle, and reduce the effect of testing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

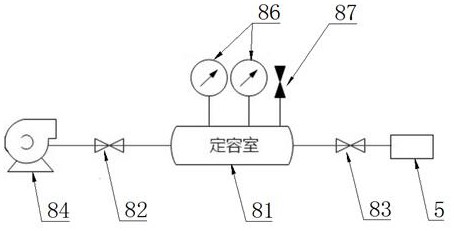

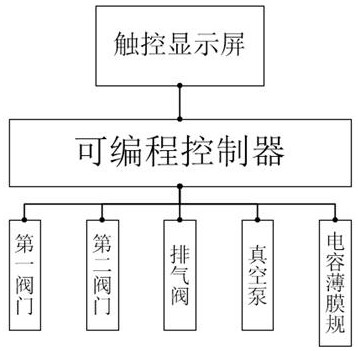

[0059] See figure 1 , A measuring apparatus for a microporous leakage of a injection glass container, comprising a sealed constant chamber 81, and the fixed capacity chamber 81 is a full metal sealing cavity structure, and the first valve 82 and the second are provided outside the set end chamber 81. Valve 83, the first valve 82 and the second valve 83 correspond to the position of the positioning chamber 81 in the longitudinal direction, and the other end of the first valve 82 is connected to the other end of the vacuum pump 84, the second valve 83. Used to seal the connection to be tested in the glass container 5;

[0060] An exterior capacitor film regulatory 86 (capacitor film vacuum gauge) and an exhaust valve 87 are attached to the central portion of the central portion to reduce A valve 82 and the second valve 83 into the measurement of the capacitive film gauge 86; the capacitive film regulatory 86 is used to measure the pressure in the settlement chamber 81, and the numbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com