Machine table gas path flow adjusting system and method

A technology of flow adjustment and gas path, which is applied in the direction of control/regulation system, flow control, flow control of electric devices, etc., and can solve problems such as complicated operation and delay in the delivery process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

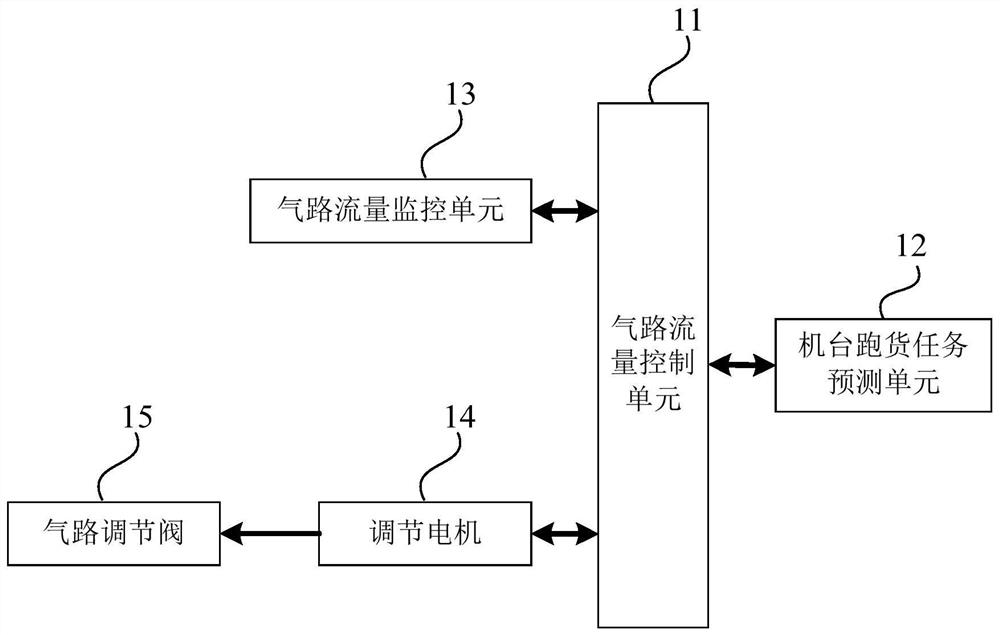

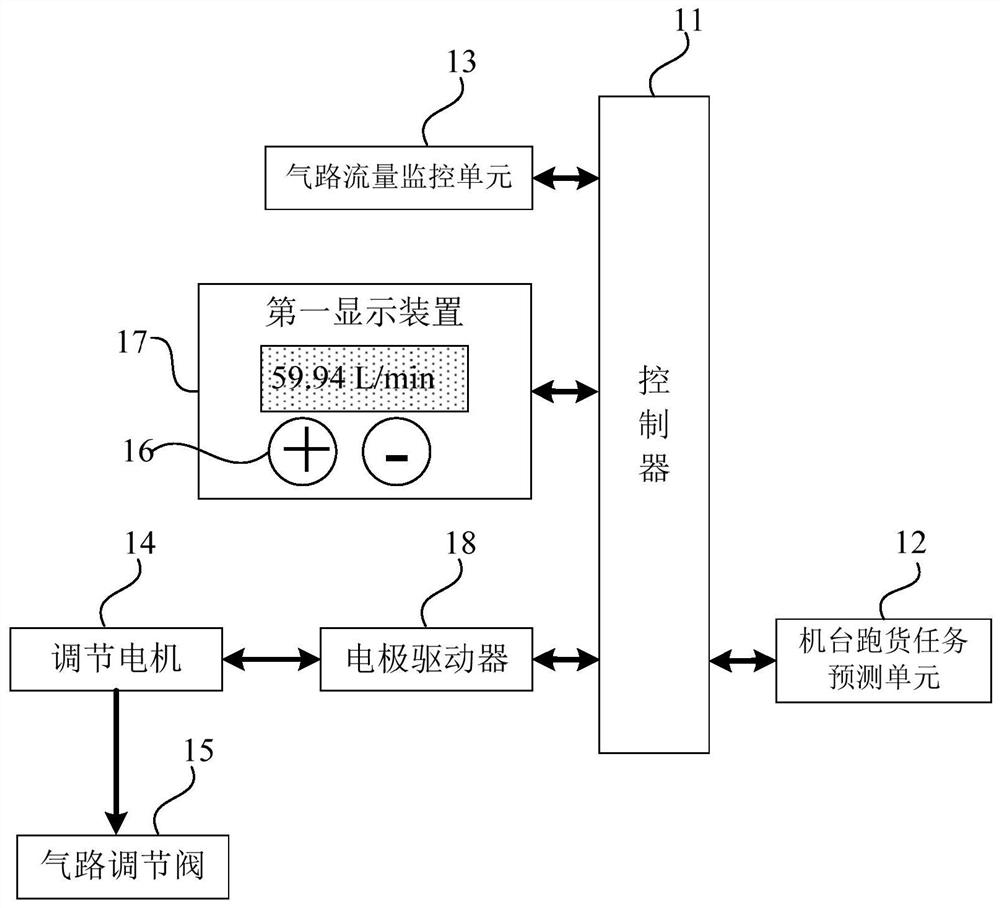

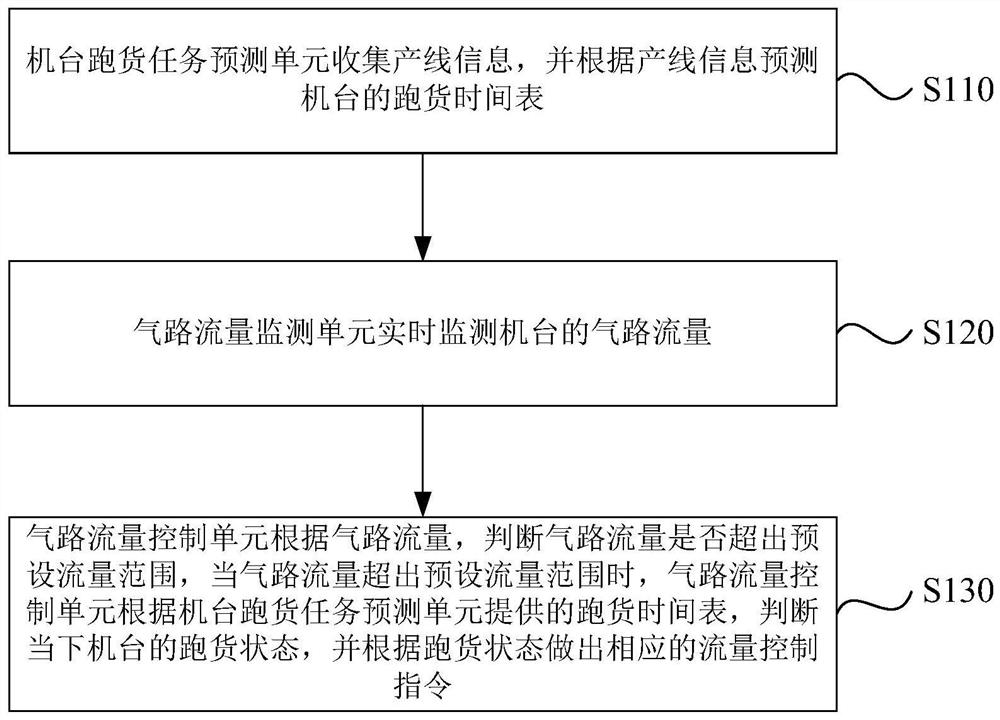

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

[0022] In the prior art, when the air flow rate is adjusted, after the pressure value of the machine exceeds the standard range, the CD measuring machine needs to be suspended, and the pressure can be increased and decreased by turning the adjusting screw of the regulating valve left and right, and the pressure value can be adjusted to within the allowable range. This operation of suspending the machine will delay the entire running process and affect the normal production efficiency. After the machine is suspende...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com