Interference filter film and its preparation method and light-emitting device

A technology of interference filtering and light-emitting devices, which is applied in semiconductor/solid-state device manufacturing, coating, gaseous chemical plating, etc. High temperature resistance and other issues, to avoid the failure of light-emitting devices, good filtering and anti-reflection performance, and improve the effect of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

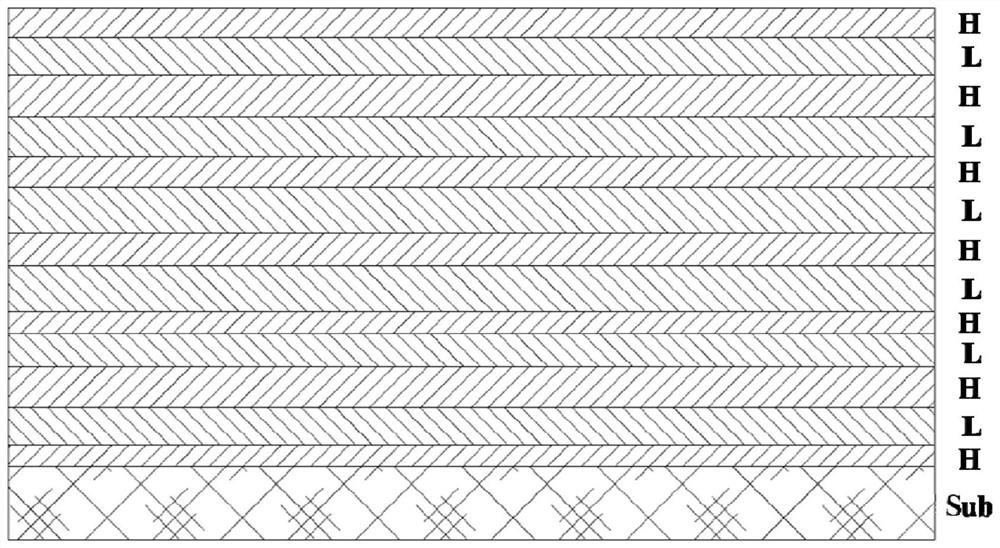

[0026] Laminated and alternated high-refractive-index material films and low-refractive-index material films are sequentially formed on the base material;

[0029] It will be appreciated that, in some embodiments, the substrate is a light-emitting device, such as an organic light-emitting device (OLED) or a quantum dot light-emitting device.

[0030] It is to be understood that a film of high refractive index material and a film of low refractive index material are relative.

[0031] The preparation method of the interference filter film of the present invention adopts atomic layer deposition (ALD) to prepare each thin film. atomic layer

[0064] An embodiment of the present invention also provides an interference filter film, using the interference filter film of any one of the above

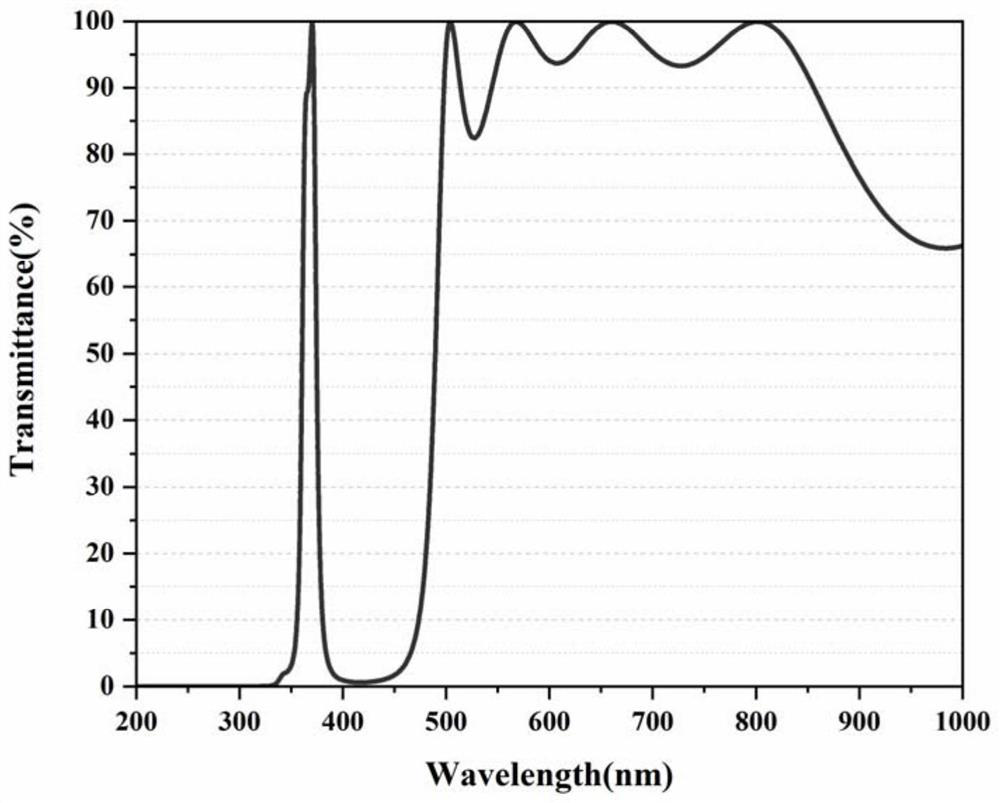

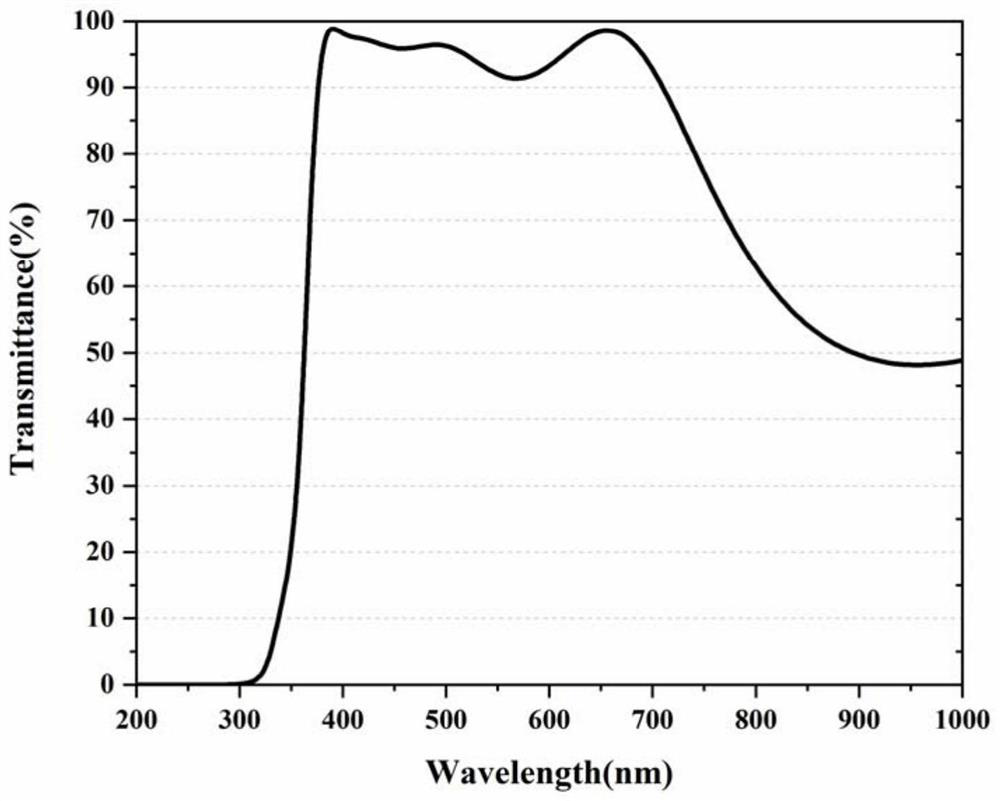

[0065] The interference filter film obtained by the preparation method of the interference filter film of the present invention has better filtering and antireflection properties.

[0069] An embod...

Embodiment 1

[0078] The temperature of the cavity is set to 100 ° C, open the suction valve to pump the cavity pressure to 5Pa and below, until the temperature is stable

[0079] (2) Repeat the above cycle step 190 times until the thickness of the interference film reaches the simulated thickness value of 20.84 nm. Should

[0082] The temperature of the cavity is set to 100 ° C, and the air extraction valve is opened to pump the cavity pressure to 5Pa and below, until the temperature is stable.

Embodiment 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com