Durable lead-acid storage battery positive electrode lead paste and preparation method thereof

A technology of lead-acid battery and positive electrode paste, applied in the direction of lead-acid battery electrodes, battery electrodes, circuits, etc., can solve the problems of shortened processing cycle of positive electrode paste and short service life of lead-acid batteries, so as to improve battery performance and Production efficiency, easy plate formation, and the effect of increasing 4BS content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A durable lead-acid battery positive lead paste, including lead powder, short fiber, red lead, pure water and sulfuric acid, also includes tetrabasic lead sulfate (4BS) and carbon black, the amount of lead powder is 100 parts, short fiber 0.2 parts for red lead, 9 parts for red lead, 1 part for tetrabasic lead sulfate (4BS), 1.5 parts for carbon black, 13-14 parts for pure water, and 11 parts for sulfuric acid parts, the concentration of sulfuric acid is 50%.

[0033] Adding tetrabasic lead sulfate (4BS) can increase the 4BS content in the lead-acid battery plate and improve the 4BS crystal size. It can greatly accelerate the formation of 4BS during the paste and subsequent curing process, even at a slightly lower temperature. Formed quickly, adding carbon black can improve the porosity of the plate and the conductive network.

Embodiment 2

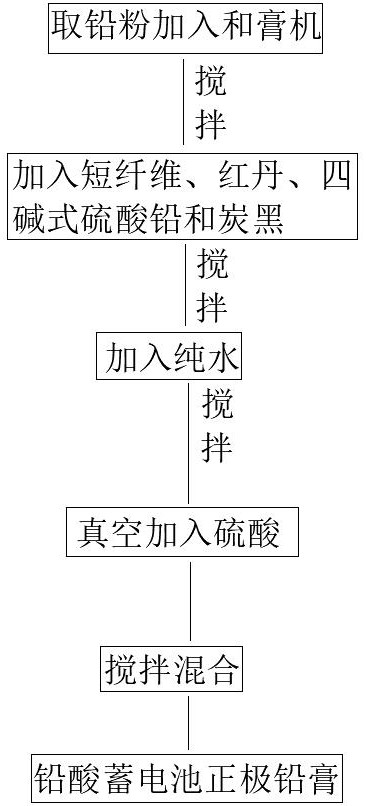

[0035] refer to figure 1 , a kind of preparation method of durable type lead-acid accumulator anode lead paste, comprises the following steps:

[0036] S1: Take 100 parts of lead powder and put it into the paste mixing machine for dry mixing;

[0037] S2: Add 0.2 parts of short fiber, 9 parts of red lead, 1 part of tetrabasic lead sulfate (4BS), and 1.5 parts of carbon black;

[0038] S3: Add 13-14 parts of pure water and continue stirring:

[0039] S4: Add 11 parts of 50% sulfuric acid, and continue to stir the lead paste evenly when adding;

[0040] S5: final mixing for 10 min.

[0041] The dry stirring time in S1 is controlled at 3 minutes, and the dry stirring for 3 minutes makes the lead powder that may be agglomerated be stirred away.

Embodiment 3

[0043] refer to figure 1 , a kind of preparation method of durable type lead-acid accumulator anode lead paste, comprises the following steps:

[0044] S1: Take 100 parts of lead powder and put it into the paste mixing machine for dry mixing;

[0045] S2: Add 0.2 parts of short fiber, 9 parts of red lead, 1 part of tetrabasic lead sulfate (4BS), and 1.5 parts of carbon black;

[0046] S3: Add 13-14 parts of pure water and continue stirring:

[0047] S4: Add 11 parts of 50% sulfuric acid, and continue to stir the lead paste evenly when adding;

[0048] S5: final mixing for 10 min.

[0049] The time for adding pure water to S3 is controlled at 2-3 minutes, and the mixing time is controlled at 5 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com