3D printing metal base movable denture, tooth boiling box and production process

A 3D printing and removable denture technology, applied in the field of dentures, can solve the problem of easy damage of the outer layer of the package, and achieve the effect of reducing the risk of detachment, improving strength and ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

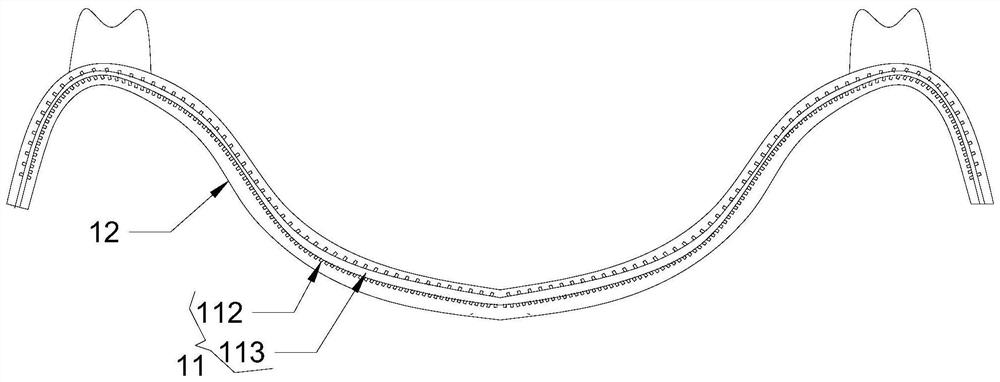

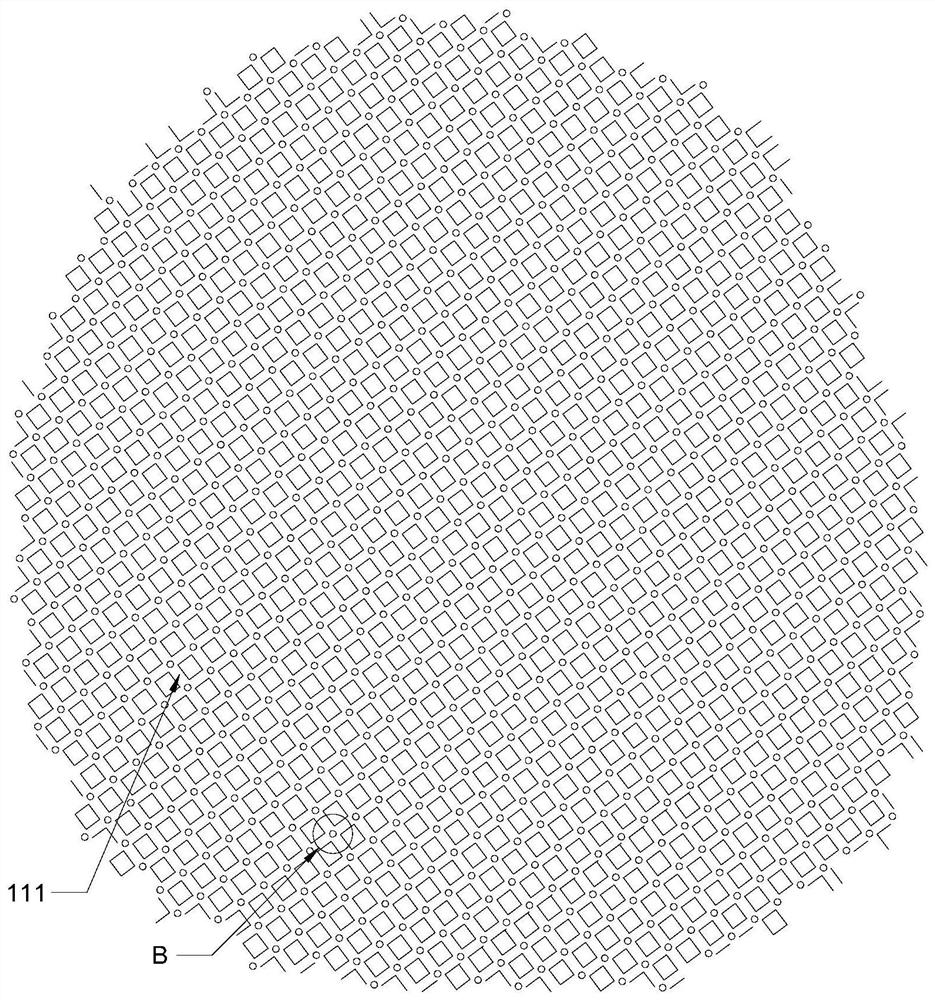

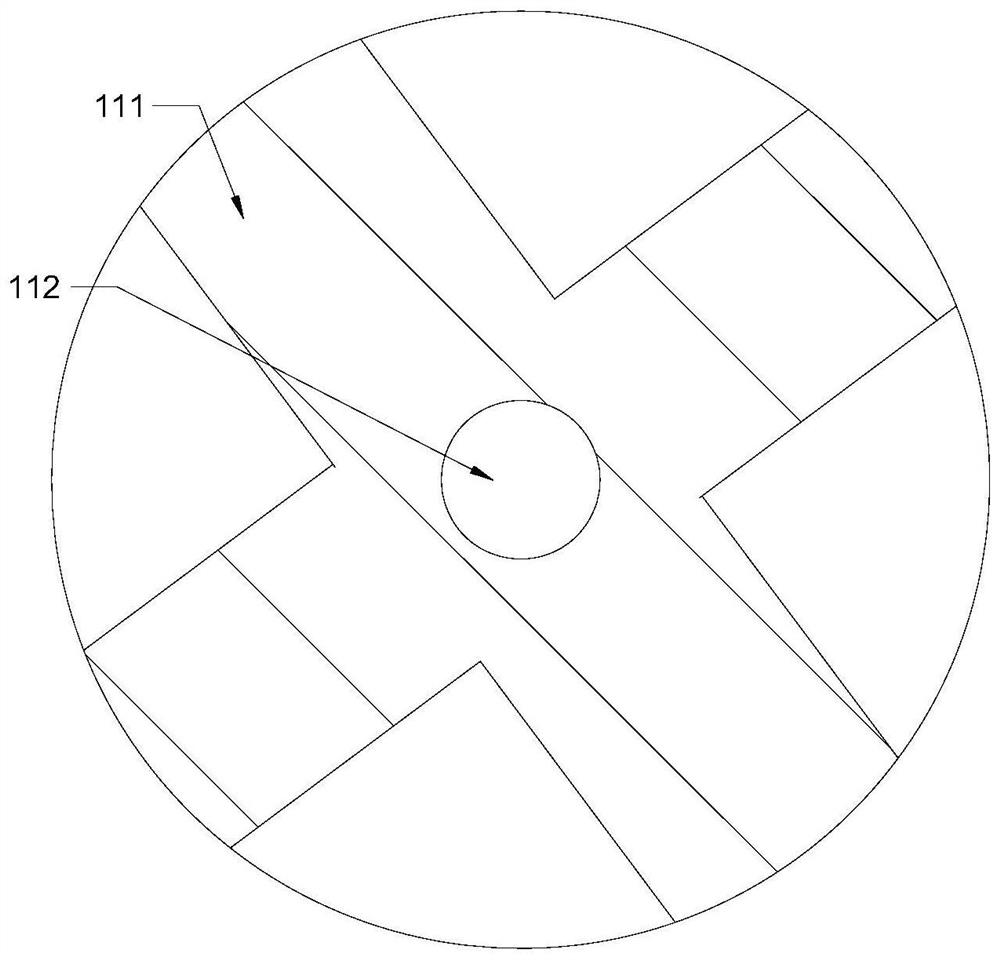

[0046] Such as figure 1 , figure 2 , image 3 as well as Figure 7 As shown, the present invention first proposes a 3D printed metal base removable denture, including: a base and an outer layer, and the outer layer is wrapped outside the base;

[0047] The base includes: a plate-shaped net frame and connecting feet, and a plurality of connecting feet protrude from the plate-shaped net frame, and the connecting feet extend into the outer layer.

[0048] The plate-shaped grid frame and connecting feet are made of stainless steel, and the outer layer is made of resin material.

[0049] In order to ensure thermal conductivity, the side of the connecting instep away from the plate-shaped grid is a heat-conducting surface, and the heat-conducting surface leaks from the outer layer.

[0050] Dental base resin, so that it tightly wraps the metal grid substrate from the inside to the outside. The internal voids of the mesh structure are all filled with resin materials, which is di...

Embodiment 2

[0058] Such as Figure 4 as well as Figure 5 As shown, the present invention also proposes a dental cooking box, including: a box body, a box cover, an intermediate ring, a first through pipe, a second through pipe, a release paper and a pressing device, and the bottom of the box body is filled with the first coating layer, the denture wax-up is placed in the middle of the box body, and the denture wax-up is surrounded by release paper. The covering layer, the first covering layer and the second covering layer wrap the denture wax-up, and the first through pipe is installed in the box body, and the first through pipe is used for contacting with the denture wax-up, and the second through-tube is installed on the box cover. The through pipe, the second through pipe is used for contacting with the denture wax pattern, and the pressing device is installed on the box cover, and the pressing device is used for close contact with the second covering layer.

[0059] In order to avo...

Embodiment 3

[0068] Such as Figure 6 As shown, the present invention also proposes a 3D printing metal base removable denture production process, including the following steps:

[0069] S1. Use the scanner to scan the impression to scan out the human oral cavity model, and the scanner transmits the human oral cavity model to the design computer;

[0070] S2. On the design computer, design a data plate-shaped grid model according to the human oral cavity model, and send the data plate-shaped grid model to the 3D printing system;

[0071] S3. The 3D printing system prints out the plate-shaped grid according to the data plate-shaped grid model;

[0072] S4. Make a wax-type base: S41. Use the impression to make a plaster model of the human oral cavity, and place the plaster model on the occlusal clip; S42. Make a denture wax-type on the plaster model of the human oral cavity, and wrap it on the base with wax Outside the plate-shaped grid, the wax acts as an outer layer to cover the plate-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com