Textile wastewater treatment method

A textile waste water and waste water technology, applied in the textile field, can solve problems such as poor use effect, change of chemical reagent addition amount, inability to continuously treat waste water, etc., and achieve the effect of avoiding excess or too little, avoiding precipitation and stratification, and facilitating recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

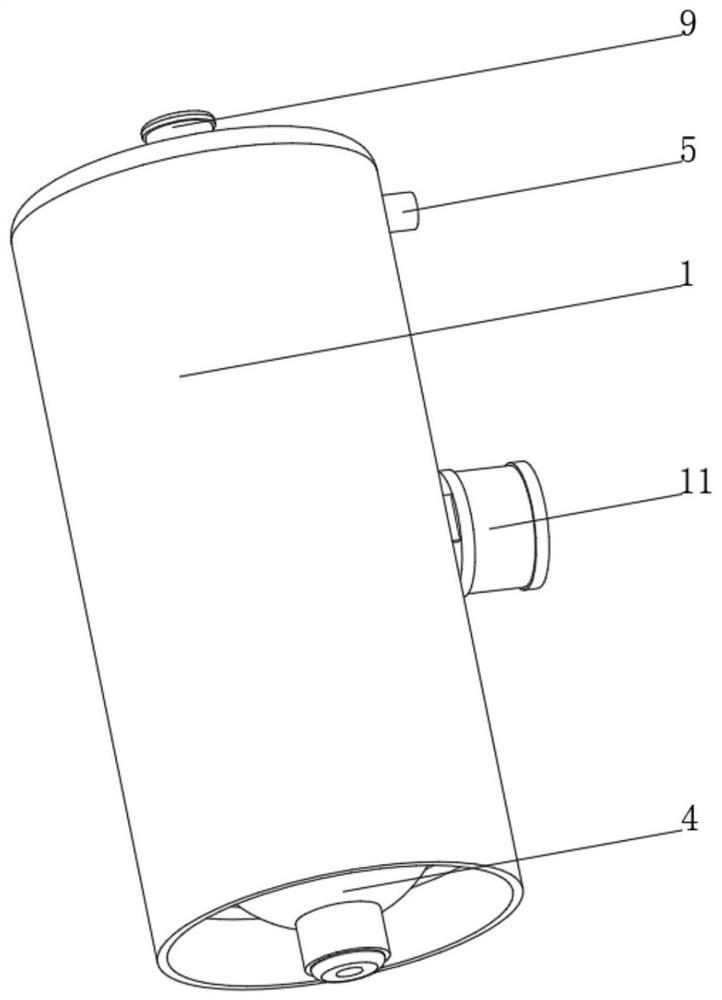

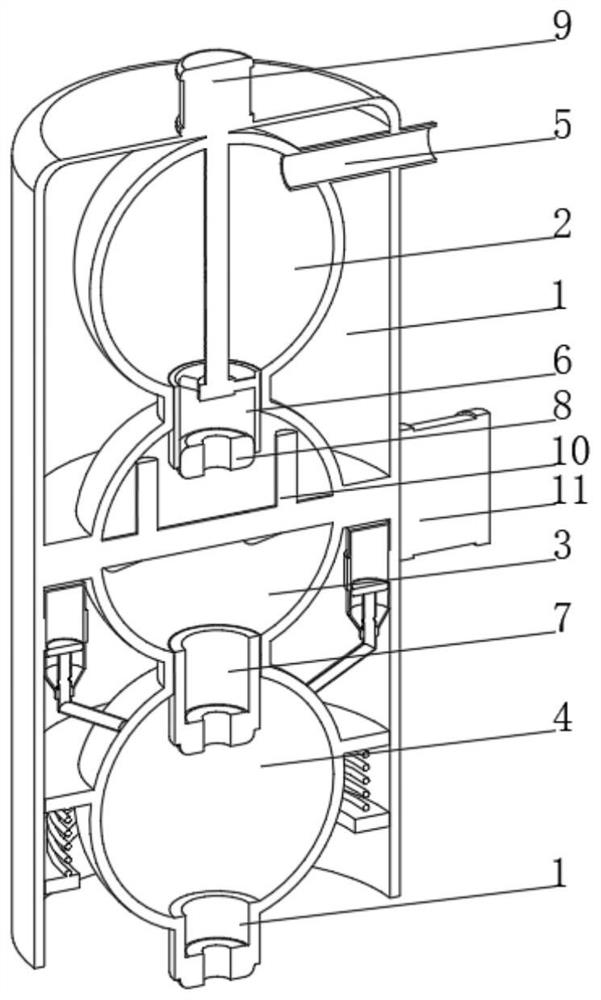

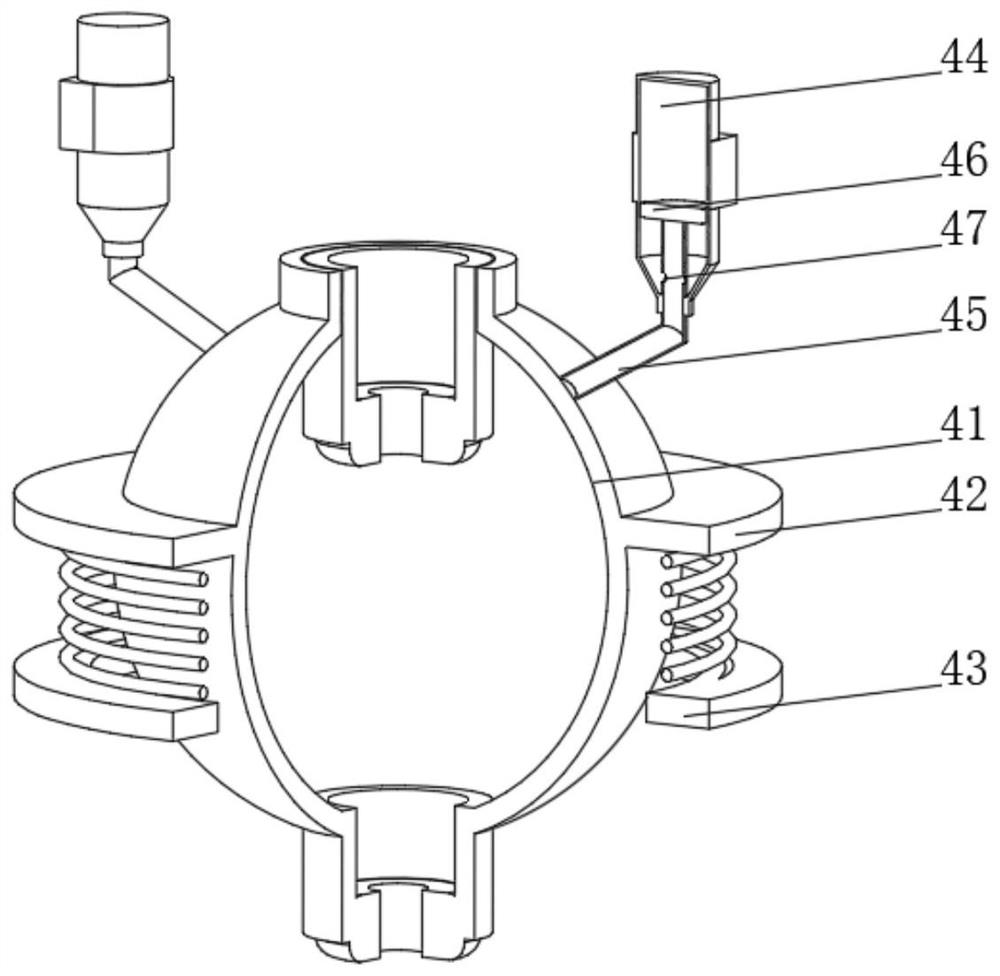

[0040] see Figure 1-5 , the present invention provides a technical solution: a textile wastewater treatment device, specifically comprising:

[0041] Treatment cylinder 1, the interior of the treatment cylinder 1 is fixedly connected with a reserve box 2, a pretreatment box 3 and a treatment device 4 in order from top to bottom, and a treatment pipe 6 is communicated between the reserve box 2 and the pretreatment box 3, and the pretreatment box 3 There is a drainage pipe 7 connected with the processing device 4, and the bottom of the inner wall of the processing pipe 6 and the drainage pipe 7 is provided with an electronic water valve 8, and the top side of the reserve tank 2 is connected with a liquid inlet pipe 5;

[0042] Pretreatment device 9, the pretreatment device 9 is arranged on the top of the reserve box 2, the bottom of the pretreatment device 9 runs through the reserve box 2 and extends to the inside of the processing pipe 6;

[0043] Stirring rod 10, the stirrin...

Embodiment 2

[0054] According to above-mentioned a kind of textile waste water treatment device, propose a kind of textile waste water treatment method now, comprise the following steps:

[0055] S1. Discharge the waste water into the pretreatment tank through the liquid inlet pipe. When the waste water in the pretreatment tank reaches a certain amount, the electronic water valve inside the treatment pipe opens, and the waste water in the reserve tank enters the pretreatment tank through the treatment pipe. At this time The liquid inlet pipe on the top of the reserve tank continuously discharges waste water into the reserve tank. Since the water passing speed of the electronic water valve inside the treatment pipe is faster than the water inlet speed of the liquid inlet pipe, when the pretreatment tank is filled with waste water, the inside of the treatment pipe The electronic water valve is closed;

[0056] S2. When the waste water in the pre-treatment tank reaches a certain amount again,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com