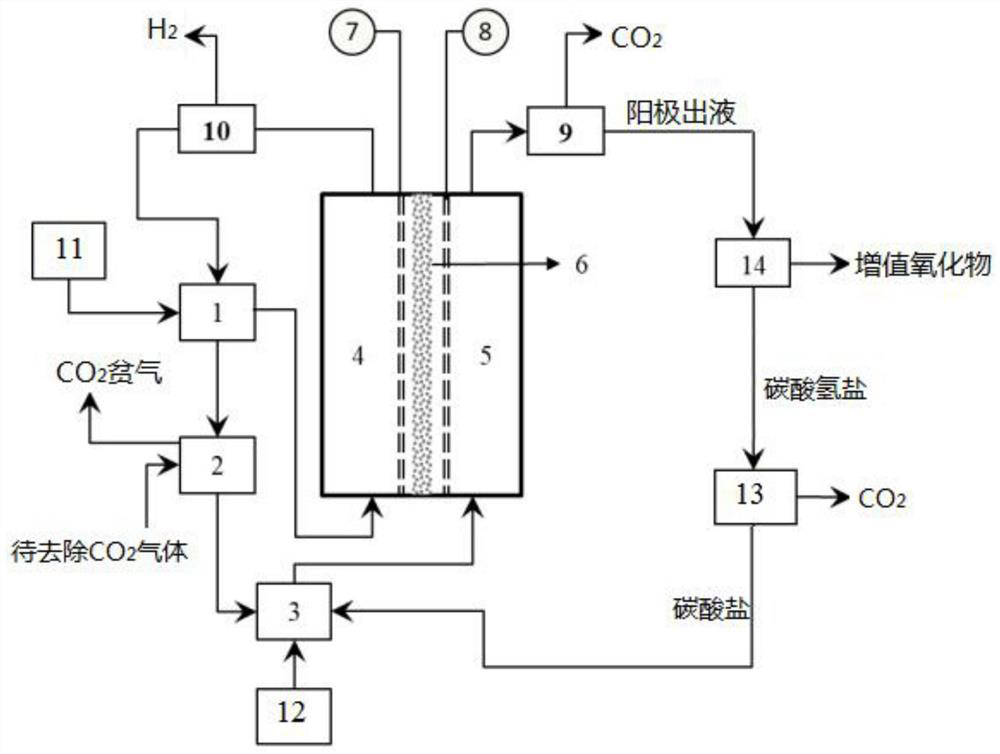

Method and system for realizing hydrogen production, organic matter oxidation, carbon dioxide absorption-desorption and hydroxide regeneration

A hydroxide and carbon dioxide technology, applied in the field of hydrogen production, carbon dioxide absorption-desorption, hydroxide regeneration, and organic oxidation, can solve the problems of difficult separation, single function, desorption, and low separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] The aqueous solution containing potassium carbonate and glycerol is used as the anode liquid (concentration of potassium carbonate is 2.5mol / L, and the concentration of glycerin is 1.2mol / L), and the potassium hydroxide solution (concentration is 6mol / L) is used as the cathode liquid, and the anode The liquid and the cathode feed liquid are respectively passed into the anode chamber and the cathode chamber of the electrolytic cell for electrolysis, and the current density is 3000A / m 2 , the oxidation reaction of glycerol at the anode mainly forms dihydroxyacetone, while potassium carbonate is converted to potassium bicarbonate and CO 2 ; A hydrogen evolution reaction occurs at the cathode, producing H 2 and KOH;

[0066] The concentration of potassium hydroxide in the cathode effluent rises to 7-7.8mol / L, 20% is diluted with water to 6mol / L, and returned to the cathode influent, and 80% is diluted with water to 5.0-5.1mol / L for CO 2 capture absorption.

[0067] Use 5...

Embodiment 2

[0070] The aqueous solution containing sodium carbonate and glucose is used as the anode liquid (the concentration of sodium carbonate is 1.5 mol / L, and the concentration of glucose is 1 mol / L), and the sodium hydroxide solution (the concentration is 6 mol / L) is used as the cathode liquid, and the anolyte is and the cathode liquid are respectively passed into the anode chamber and cathode chamber of the electrolytic cell for electrolysis, and the current density is 1500A / m 2 , the oxidation reaction of glucose at the anode mainly forms gluconic acid, and at the same time forms NaHCO 3 , and release CO 2 gas; a hydrogen evolution reaction occurs at the cathode, producing H 2 and NaOH.

[0071] The concentration of sodium hydroxide in the cathodic effluent rises to 3.2-4mol / L, and 10% of the cathodic effluent is diluted with water to 2 mol / L, and returned to the cathode influent, and 90% of the cathodic effluent is diluted with water to 2.9-3mol / L. in CO 2 capture absorption...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap