Fireproof smoke isolation door plate assembly for textile workshop station

A door panel and smoke isolation technology, which is applied to fire doors, anti-virus doors, door leaves, etc., can solve the problems of door panel damage, single function of fire and smoke insulation door panels, and inability to extinguish fires, etc., to achieve the effect of increasing the spraying area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

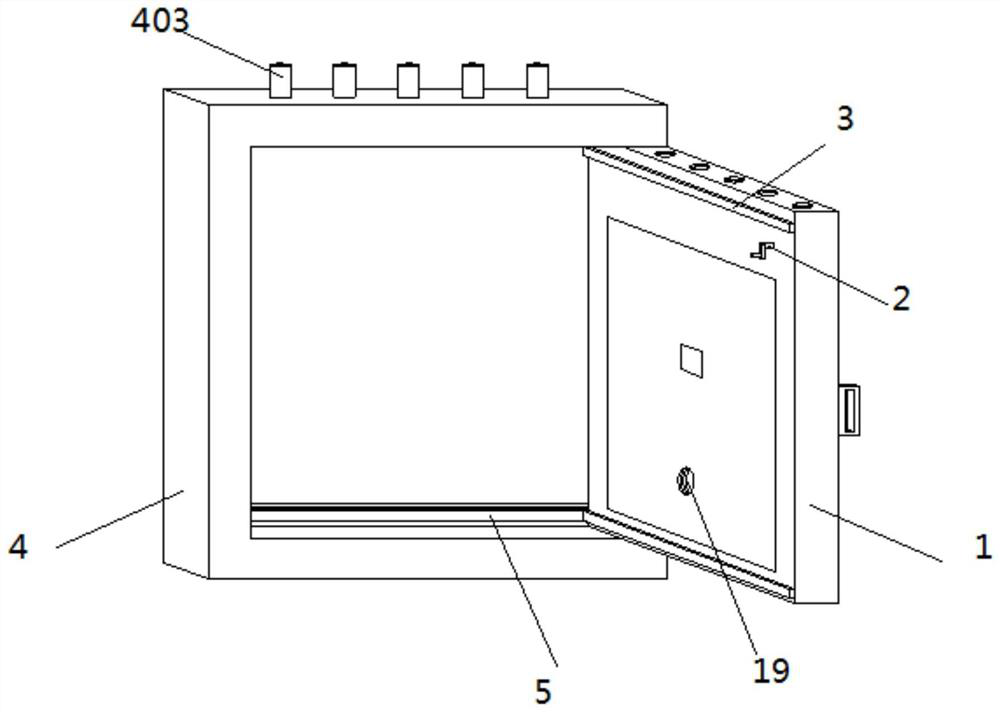

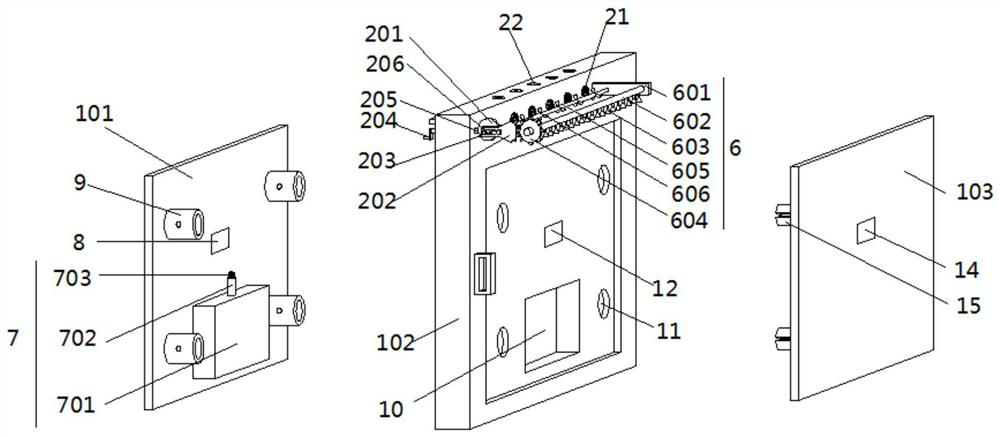

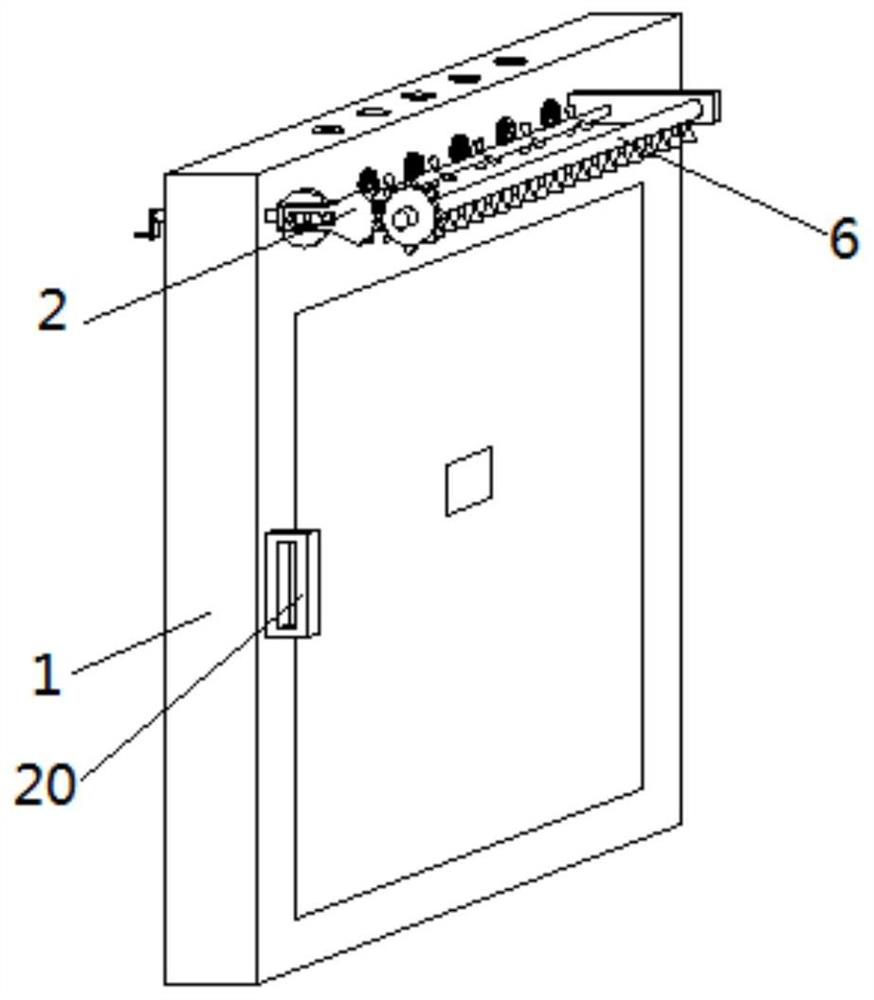

[0031] as attached figure 1 To attach Figure 9Shown: a fire-resistant and smoke-proof door panel assembly for a textile workshop, including a fire-resistant door panel assembly 1, a drive assembly 2, a door frame 4, a smoke-isolation device 5, a water spray device 6, and a door handle 20. The fire-resistant door panel assembly 1 is installed on the door frame 4 On the inner side, the fire door panel assembly 1 includes an outer door panel 101, a door panel substrate 102, and an inner door panel 103. The outer door panel 101 and the inner door panel 103 are respectively engaged and clamped with the left and right sides of the door panel substrate 102, and the outer door panel 101 and the inner door panel 103 are also engaged and clamped. The front and rear sides of the door frame 4 are fixedly connected with a sealing strip 401. The top of the door frame 4 is equidistant and vertically fixedly connected with a smoke exhaust pipe 403. The smoke exhaust pipe 403 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com