Truss type double-wall heat insulation device for engine combustion chamber and cold air film forming method

A technology of heat insulation device and combustion chamber, which is applied in the direction of combustion method, combustion chamber, continuous combustion chamber, etc., can solve problems such as increasing engine life and reducing air flow, reducing cooling pressure, improving life and reliability, and improving effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

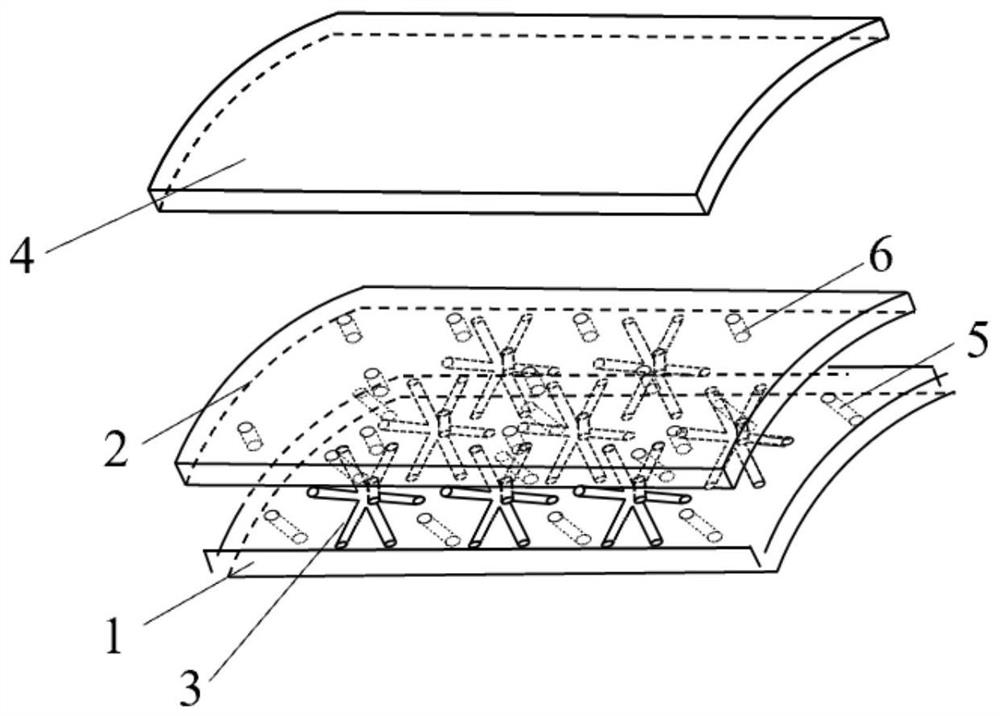

[0030] Embodiment 1: as figure 1 , figure 2 , image 3 Shown, a kind of truss type double-wall thermal insulation device for engine combustion chamber, comprises the gas film orifice plate layer 1 that is used to form the inner wall of the combustion chamber barrel and the impact orifice plate layer on the gas film orifice layer (outside 2. The inner side of the gas film orifice layer 1 is the main gas duct (8) of the combustion chamber, and the impact orifice layer 2 and the outer wall surface 4 of the combustion chamber together form the cold air duct 7; the gas film orifice layer 1 and the impact hole The cavity between the slabs 2 is provided with sandwich Pozierian trusses 3 arranged in a matrix; the air-film orifice plate layer 1, the impact orifice plate layer 2 and the sandwich Pozierian trusses 3 together form a double-wall heat insulation screen;

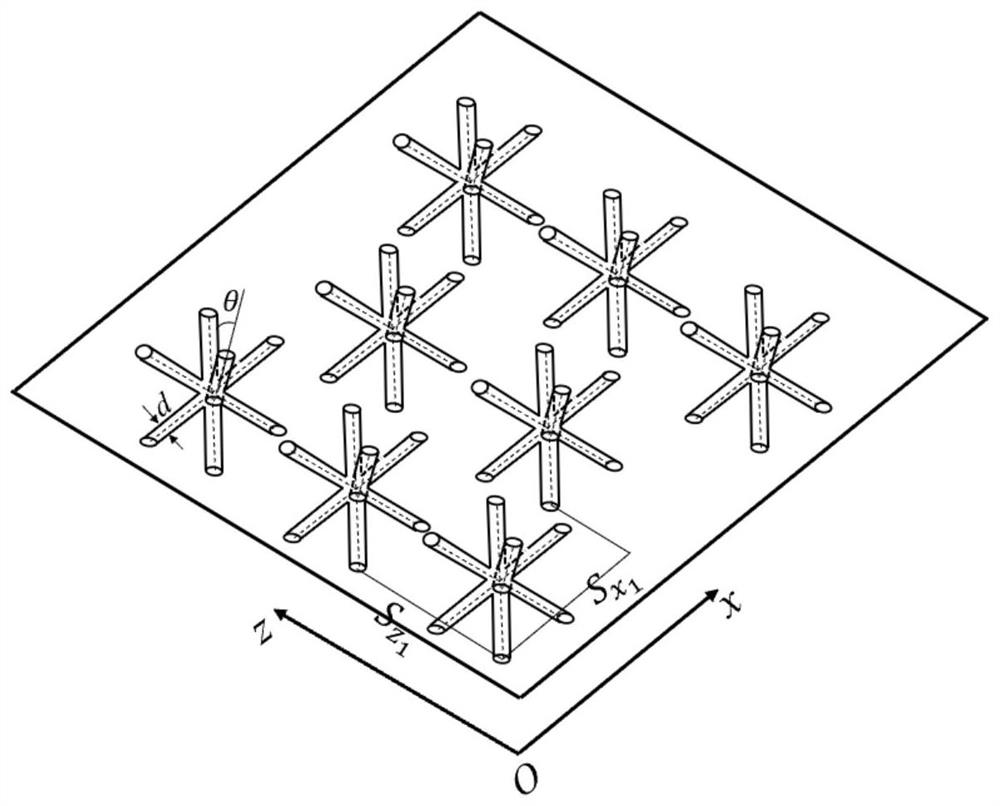

[0031] The sandwich rice-shaped truss 3 is composed of four truss rods, the midpoints of the four truss rods cross ea...

Embodiment 2

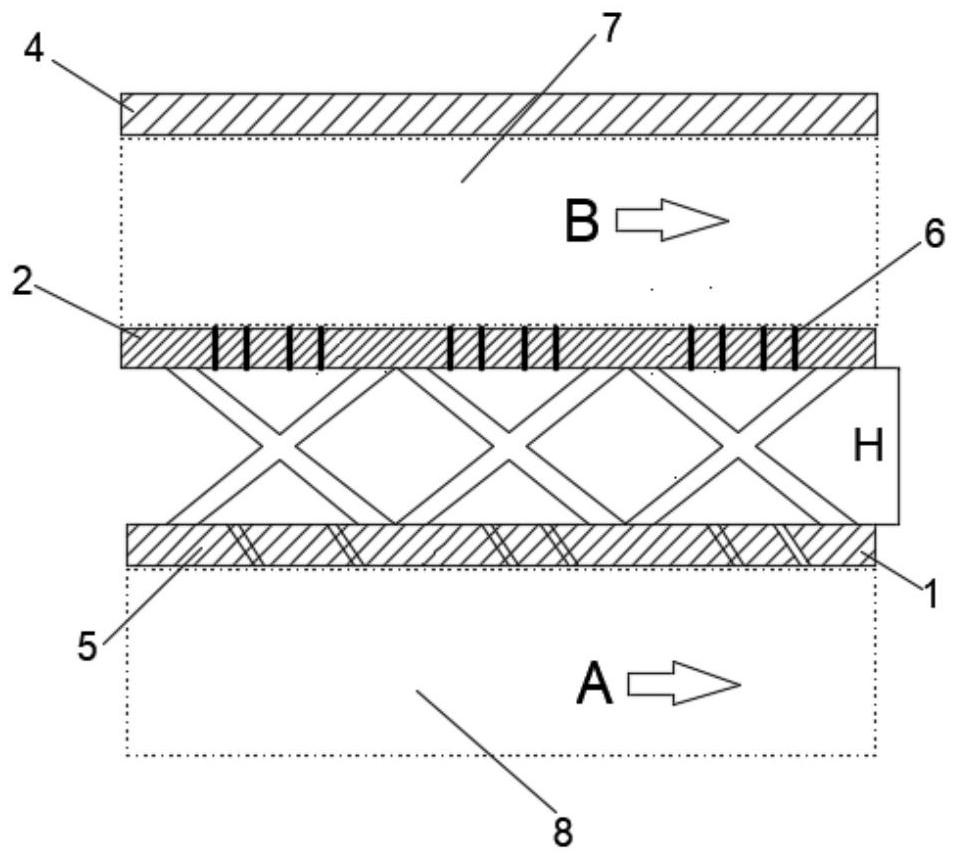

[0040] Embodiment 2: as Figure 4 , Figure 5 As shown, the present invention also provides a method for forming an air film on an air film orifice in a truss type double-wall insulation device for an engine combustion chamber, the steps are as follows:

[0041] Part of the cooling air flow B in the cold air duct 7 is perpendicular to the impact jet C1 of the impact orifice plate 2, and enters the cavity between the air film orifice plate 1 and the impact orifice plate 2 through the impact hole 6 on the impact orifice plate 2 ;

[0042] The impact jet C1 entering the cavity between the air film orifice plate 1 and the impact orifice plate 2 is a part of the impact jet that directly impacts and cools the inner wall of the air film orifice plate 1 to form an impact cooling air flow C3, and the other part impacts the sandwich rice word truss 3, and collide with the surface of the sandwich truss 3 to form a flow C2 around the sandwich truss 3,

[0043] A part of the bypass flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com