Portable dust monitor

A monitor and portable technology, applied in the field of portable dust monitors, can solve problems such as manual calibration, instrument drift, optical window pollution, etc., achieve the effects of stabilizing fluid pressure and flow, eliminating gas pressure pulsation, and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below.

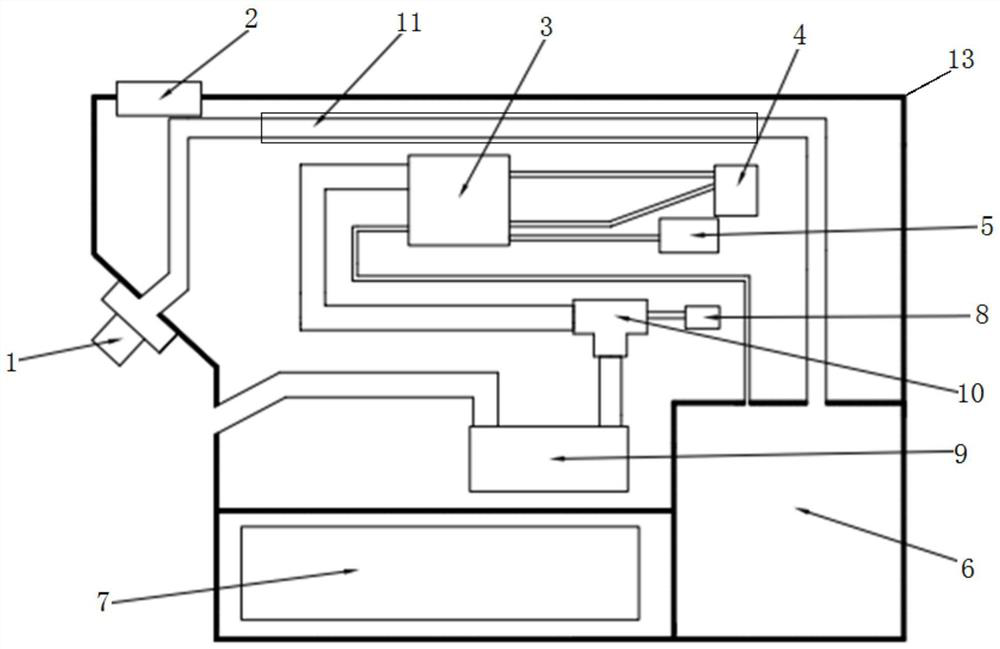

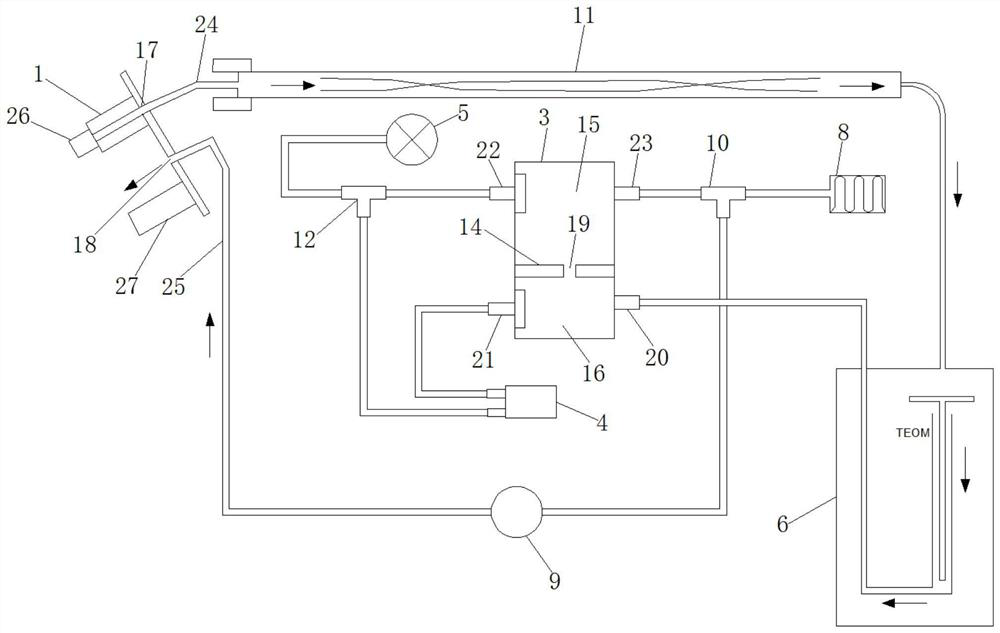

[0027] Such as figure 1 and figure 2 As shown, the present invention provides a portable dust monitor, including a small housing 13, the small housing 13 is provided with a main air inlet 17 and a main exhaust port 18, and also includes a small housing 13 inside Temperature and humidity measuring box 3, dust measuring instrument 6, drying pipeline 11, first three-way pipe fitting 10, pulsation damper 8, vacuum sampling pump 9, environmental pressure sensor 5, differential pressure flowmeter 4, battery pack 7 and controller;

[0028] The middle part of the cavity of the temperature and humidity measurement box 3 is equipped with a partition 14, and the cavity of the temperature and humidity measurement box 3 is isolated by the partition 14 into an upper cavity space 15 and a lower cavity space 16, and the partition 14 The middle part is provided with a strip-shaped communication hole 19 communicating with the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com