Method for evaluating service life of organic coating in seawater total immersion environment

An organic coating and environmental technology, which is applied in the field of life evaluation of organic coatings in the environment, can solve the degradation of coating electrochemical characteristics and the ability to isolate the corrosive environment, and cannot evaluate the anti-corrosion performance of organic anti-corrosion coatings. To achieve the effect of timely, accurate and reasonable criterion, simple test method and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be described in further detail below in conjunction with examples.

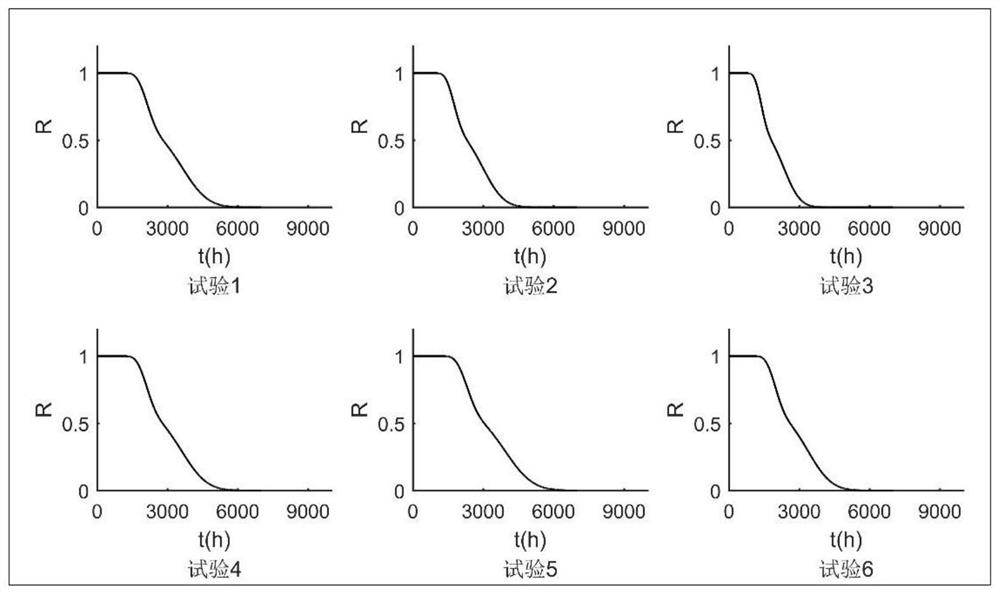

[0074] An organic coating structure uses polyurethane series coatings as the topcoat, and the overall thickness of the coating system is about 80 μm; the test is to conduct immersion tests on the polyurethane coating system in 8 test environments; the specific test conditions and conditions during the aging process of the coating The low-frequency impedance data records are shown in Table 1;

[0075] Table 1 Polyurethane coating system immersion test data

[0076]

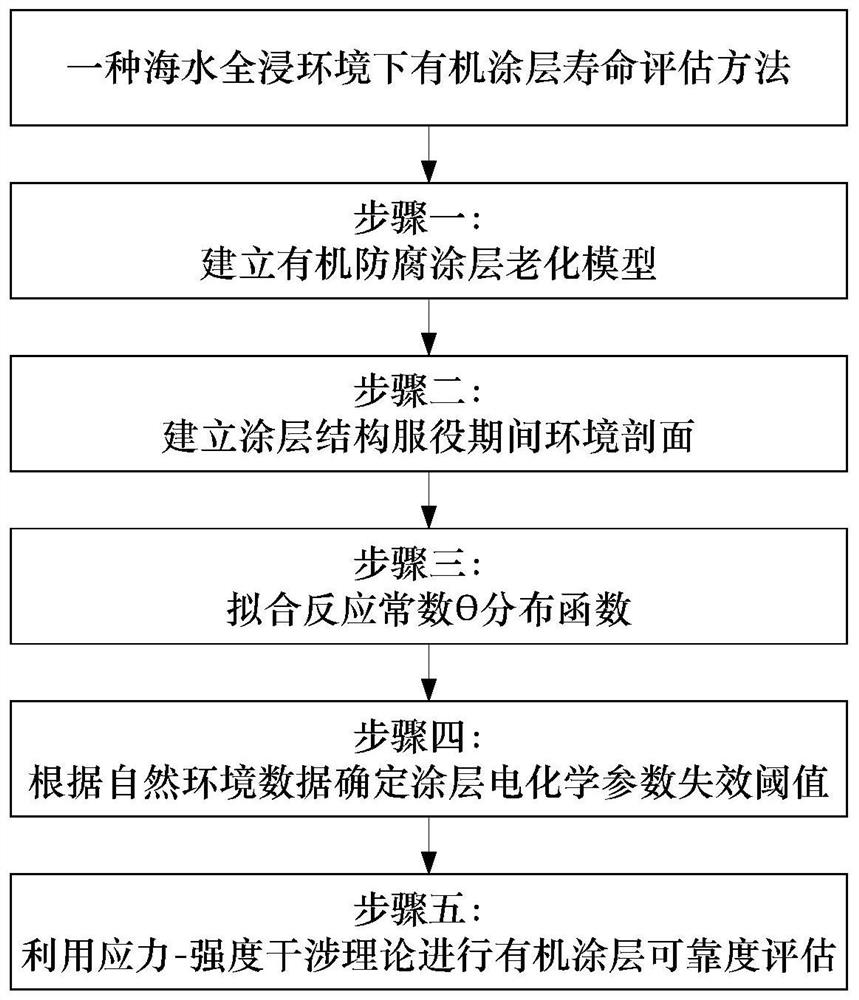

[0077] The present invention is a method for evaluating the life of an organic coating in a seawater immersion environment, that is, a method for evaluating the life of an organic coating in a seawater immersion environment considering the influence of temperature and chloride ions, see figure 1 As shown, it is realized through the following steps:

[0078] Step 1: Establish the aging model of organic anti-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com