Integrally molded universal waterproof magic cube base plate

A molding, integrated technology, applied in water supply devices, waterway systems, drainage structures, etc., can solve the problems of complex process, poor quality stability, high cost, and achieve the effect of low process difficulty, high quality stability and high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

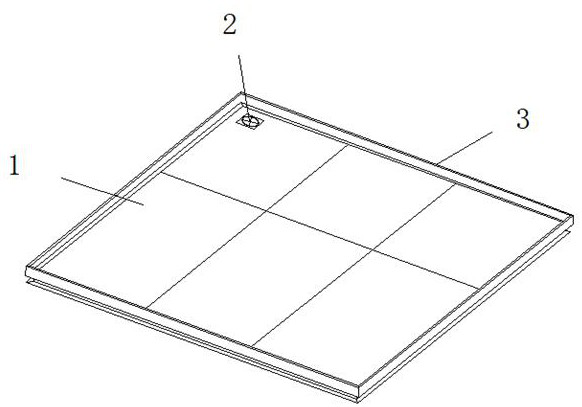

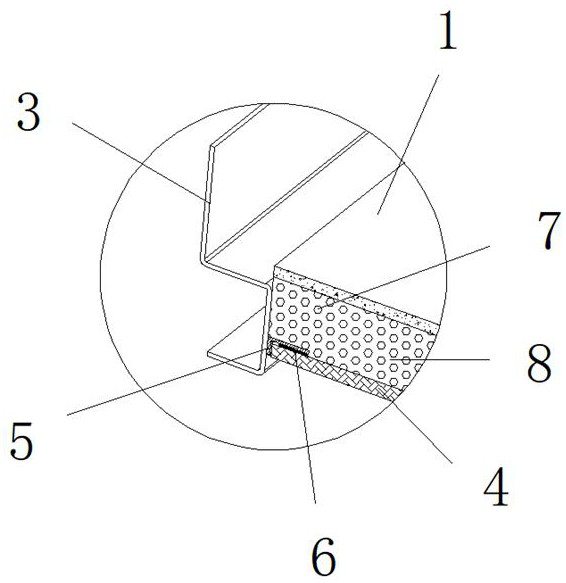

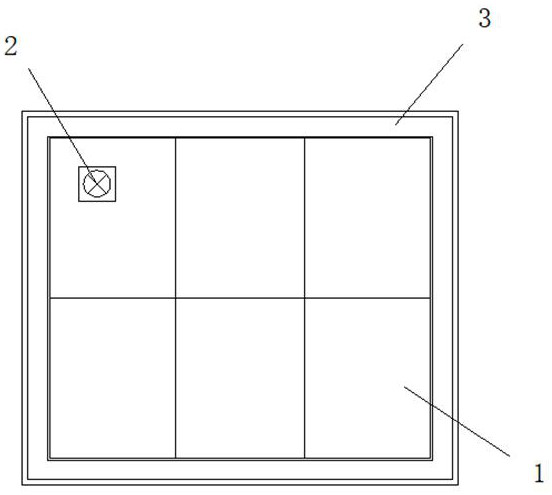

[0027] Example 1: See Figure 1-6 , an integrally molded universal waterproof Rubik's Cube chassis, including a bottom frame 3, a steel grid 7 is welded and fixed inside the bottom frame 3, an L-shaped corner bracket 5 is welded and fixed at the bottom of the bottom frame 3, and the bottom of the L-shaped corner bracket 5 The bottom plate 4 is fixedly connected, the top of the reinforcement grid 7 is provided with a facing material 1, the interior of the reinforcement grid 7 is provided with a filling material 8, and a floor drain 2 is embedded at the corner between the decoration material 1 and the inside of the bottom plate 4, The floor drain 2 communicates with the top of the facing material 1 and the bottom of the bottom plate 4;

[0028] The facing material 1 is welded after bending or rolling forming of metal steel plates. The bottom frame 3 has its own water retaining edge, and the bottom frame 3 is also formed by bending or rolling;

[0029] Specifically, such as fig...

Embodiment 2

[0030] Embodiment 2: The interior of the seam between the bottom of the L-shaped corner bracket 5 and the top of the bottom plate 4 is attached with waterproof collodion 6, and the facing material 1 can be ceramic tile, slate, stone, stone-plastic board and other materials;

[0031] A cavity is formed between the facing material 1 and the base plate 4, and the reinforcement grid 7 is supported between the facing material 1 and the base plate 4. The filling material 8 is filled in the cavity formed between the facing material 1 and the base plate 4. The filling material 8 Using PU foaming agent, the decorative material 1, the bottom frame 3, the bottom plate 4 and the steel grid 7 are filled with filler 8 to form an integrated structure;

[0032] Specifically, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, a four-layer composite structure is adopted, and the decorative material 1, the bottom frame 3, the bottom plate 4, and the steel...

Embodiment 3

[0033] Embodiment 3: the horizontal plane at the bottom of the bottom frame 3 is lower than the horizontal plane at the bottom of the bottom plate 4;

[0034] Specifically, such as figure 1 , figure 2 , Figure 5 and Image 6 As shown, the design method of sinking the installation surface is adopted, and the structure of the ground pressure wall is adopted, supplemented by the beautifying agent to close the mouth. It can fully meet the needs of existing building renovation, new building, rehabilitation nursing home, barrier-free and other complex places.

[0035] Working principle: when the present invention is in use, firstly, the facing material 1 on the chassis of the universal waterproof Rubik’s Cube is welded by bending or rolling forming of metal steel plates, and the reinforcement grid 7 is welded around the bottom frame 3 To make it into one, L-shaped corner brackets 5 are welded around the bottom frame 3, and then the welded surface is rust-proof, and waterproof ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com