Silicone oil injection and suction system for ophthalmology department

An injection suction system and silicone oil technology, applied in the medical field, can solve the problems of consumption of consumables, achieve the effects of low cost, convenient placement, and less chance of accidentally injuring the eyeball

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

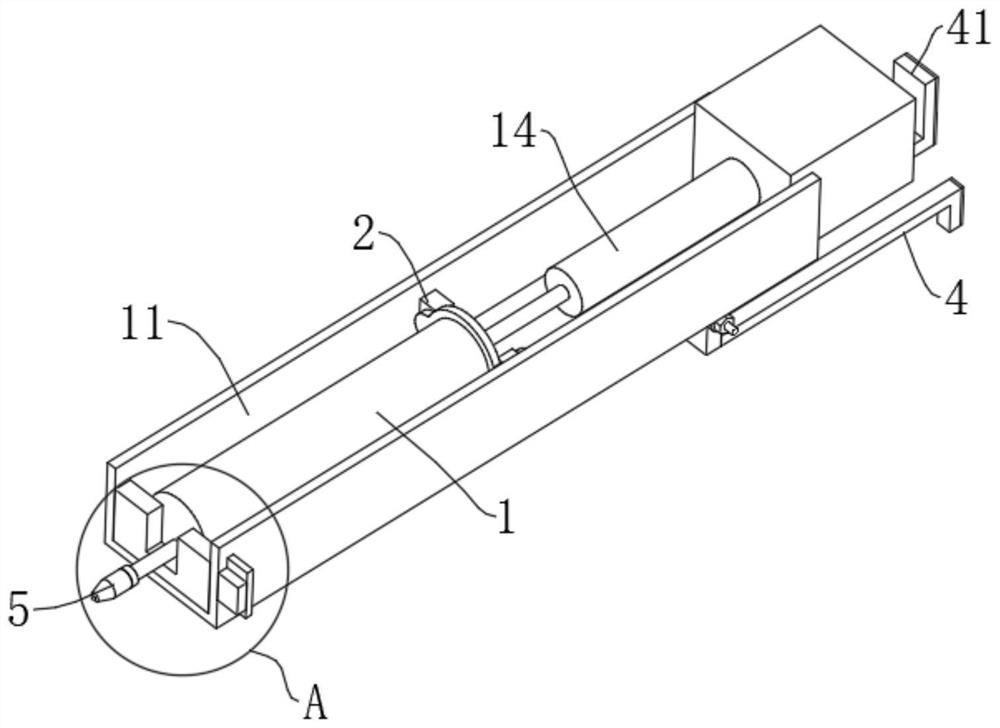

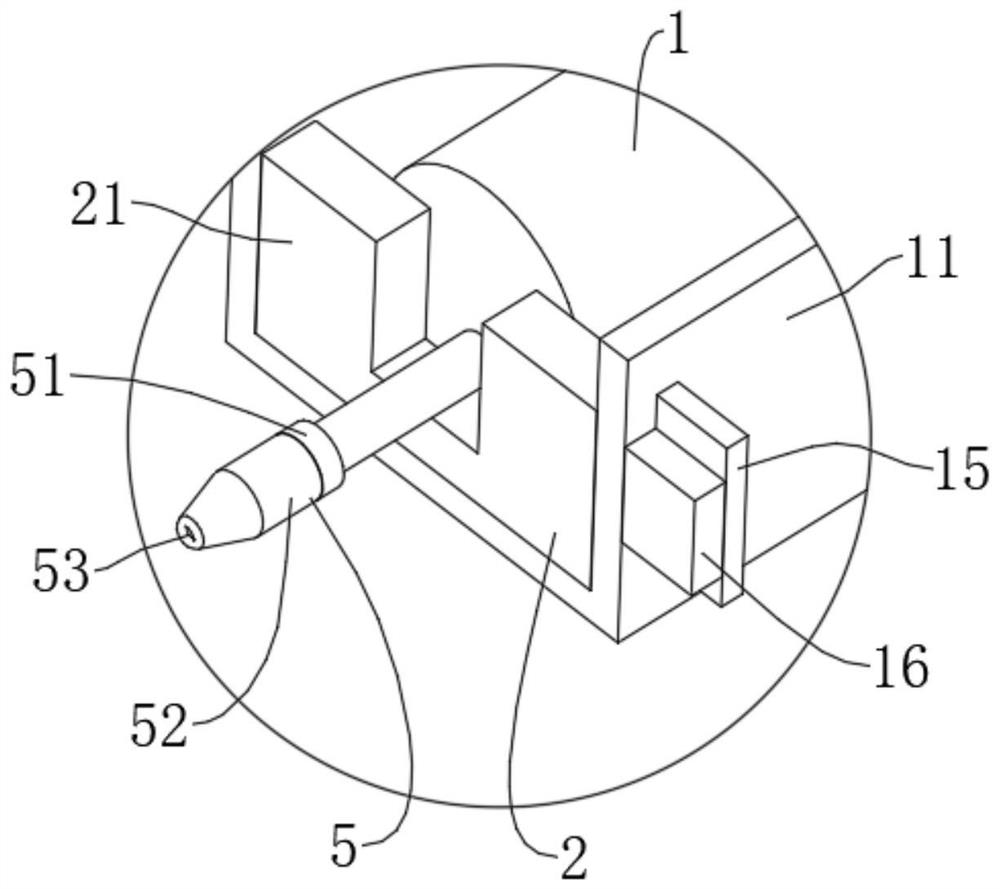

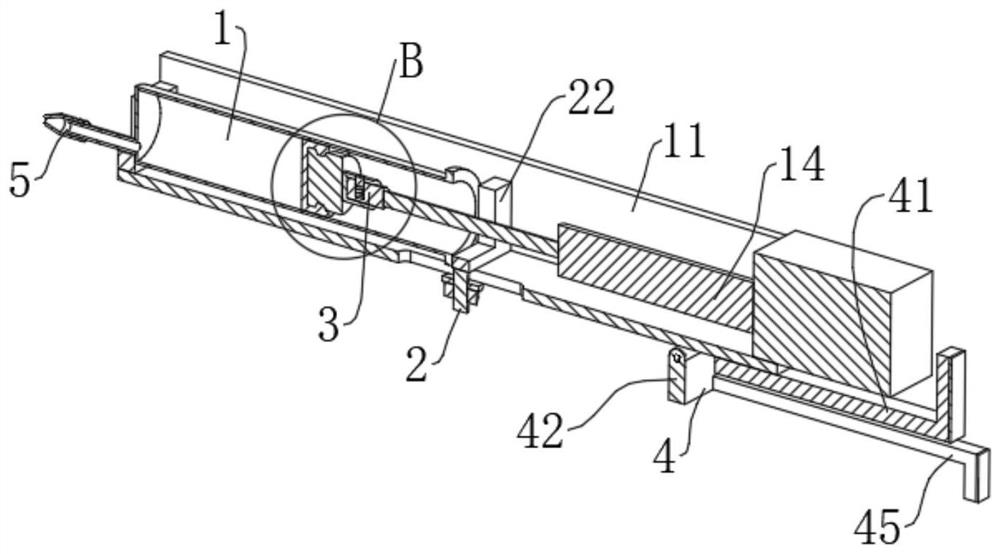

[0044] refer to Figure 1 to Figure 5 , an ophthalmic silicone oil injection and suction system, mainly includes the following parts: the tube 1 as the main body of suction and washing, and the tube 1 can choose a syringe tube; the supporting part 11 for placing the tube 1, and the supporting part 11 is the overall support of the device ; the clamping assembly 2 for fixing the tube 1 arranged on the supporting member 11, the clamping assembly 2 can be used to realize the firm fixing of the tube 1; A sealing ring 13 is arranged on the outside; the miniature push rod 14 fixed on the supporting member 11 can achieve the purpose of driving the piston 12 to slide under the action of the micro push rod 14; it is used to connect the output of the piston 12 and the miniature push rod 14 The shaft end is connected with a fixed connecting assembly 3; the placing and gathering assembly 4 arranged on the supporting member 11; the anti-bruising assembly 5 arranged at the suction port of th...

Embodiment 2

[0054] The difference from Example 1 is that the inner wall of the tube 1 is coated with an antifouling coating, wherein the preparation process of the antifouling coating is as follows:

[0055] S1. Take the following ingredients by weight: 34 parts of methyl trimethoxy silicon epoxy, 28 parts of polyurethane resin, 45 parts of acrylate, 14 parts of citric acid, 15 parts of polycarbonate, 8 parts of isopropanol, and 10 parts of acrylamide , 5 parts of methacrylate, 14 parts of polyethylene glycol, 10 parts of stannous octoate, 10 parts of dibutyltin dilaurate;

[0056] S2. Prepare the intermediate coating body: add methyltrimethoxysilane epoxy, polyurethane resin, acrylate, citric acid, and polycarbonate into a reaction kettle at 115° C. for 30 minutes to obtain an intermediate coating body;

[0057] S3. Preparation of paint: Pour the intermediate paint body into the mixer, add isopropanol, acrylamide, methacrylate, polyethylene glycol, stannous octoate, dibutyltin dilaurate ...

Embodiment 3

[0060] The difference from Example 2 is the preparation of antifouling coating, wherein the preparation process of antifouling coating is as follows:

[0061] S1. Take the following ingredients by weight: 45 parts of methyl trimethoxy silicon epoxy, 28 parts of polyurethane resin, 38 parts of acrylate, 12 parts of citric acid, 22 parts of polycarbonate, 8 parts of isopropanol, and 10 parts of acrylamide , 5 parts of methacrylate, 14 parts of polyethylene glycol, 10 parts of stannous octoate, 15 parts of dibutyltin dilaurate;

[0062] S2. Preparation of intermediate coating body: adding methyltrimethoxysilane epoxy, polyurethane resin, acrylate, citric acid, and polycarbonate into a reaction kettle at 118° C. for 30 minutes to obtain an intermediate coating body;

[0063] S3. Preparation of paint: Pour the intermediate paint body into the mixer, add isopropanol, acrylamide, methacrylate, polyethylene glycol, stannous octoate, dibutyltin dilaurate and stir to disperse at the sam...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap