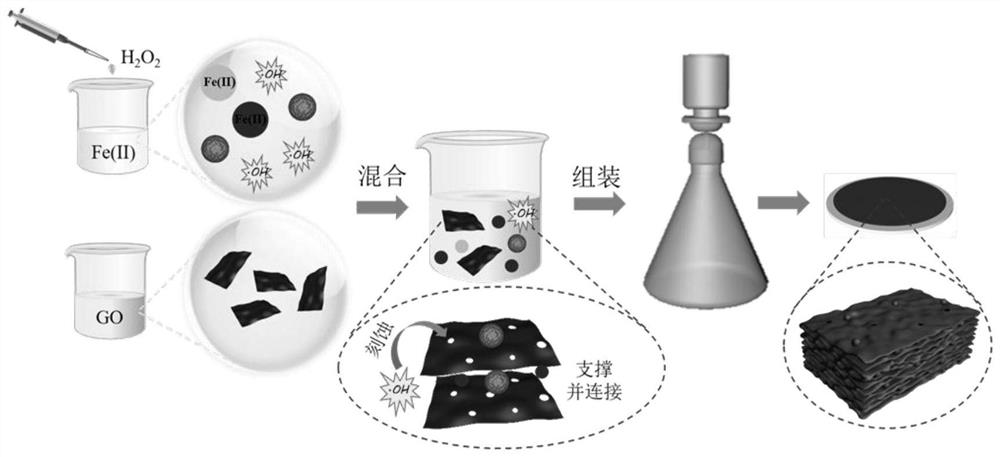

A kind of defect-rich water-stable graphene oxide film and its preparation method and application

A graphene membrane and water stabilization technology, applied in chemical instruments and methods, membrane technology, water pollutants, etc., can solve the problems of complex operation of chemical reagents, shortening the transmission path of water molecules, and difficulty in ensuring membrane stability. Good removal effect, optimized osmotic separation efficiency, and the effect of facilitating large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Preparation of graphene oxide solution

[0050] First, 1 g of NaNO was placed in an ice bath at 5°C 3 and 50 mL of concentrated H with a mass fraction of 98% 2 SO 4 Mix it into a beaker, mix it in an ice bath at 5 °C, add 2 g of natural flake graphite (325 mesh), stir for 1 h for pre-oxidation, and then add 6 g of KMnO 4 Add it slowly (add in batches within 1h, stir while adding), and then stir magnetically for 10min after the addition (in an ice bath, the temperature is less than 20°C), then raise the temperature to 35°C for another 2h, and then mix Slowly add 90mL of ultrapure water to the system. After adding water, the temperature of the system will rise rapidly. Use the released heat to continue the reaction until the temperature stops rising and begins to drop (the reaction is over at this time). After stirring for 15 minutes, add about 300mL of ultrapure water to stop. reaction, and finally adding a concentration of 30% H 2 o 2 , H 2 o 2 The amount of ...

Embodiment 2

[0056] Same as Example 1, the only difference is that H 2 o 2 and Fe 2+ H in the mixed solution 2 o 2 The concentration was 0.05mmol / L, and a graphene oxide film (Fe / GO-0.05) was obtained.

Embodiment 3

[0058] (1) Preparation of graphene oxide solution

[0059] First, 0.5 g NaNO 3 and 25 mL of concentrated H with a mass fraction of 98% 2 SO 4 Mix it into a beaker, mix it in an ice bath at 5°C, then add 1g of natural flake graphite (325 mesh), stir for 1h for pre-oxidation, and then add 3gKMnO 4 Add it slowly (add in batches within 1h, stir while adding), and then stir magnetically for 10min after the addition (in an ice bath, the temperature is less than 20°C), then raise the temperature to 35°C for another 2h, and then mix Slowly add 45mL of ultrapure water to the system. After adding water, the temperature of the system will rise rapidly. Use the released heat to continue the reaction until the temperature stops rising and begins to drop (the reaction ends at this time). After stirring for 15 minutes, add about 300mL of ultrapure water to stop. reaction, and finally adding a concentration of 30% H2 o 2 , H 2 o 2 The dosage should be determined until the solution turns...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com