Smashing and drying integrated equipment for pig feed processing

A pig feed and equipment technology, applied in lighting and heating equipment, feed, drying, etc., can solve the problems of lack of discharge and dust prevention measures, lack of drying design, difficulty in continuous feeding, etc., to achieve rapid and efficient drying, reduce Dust pollution, convenient and fast cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

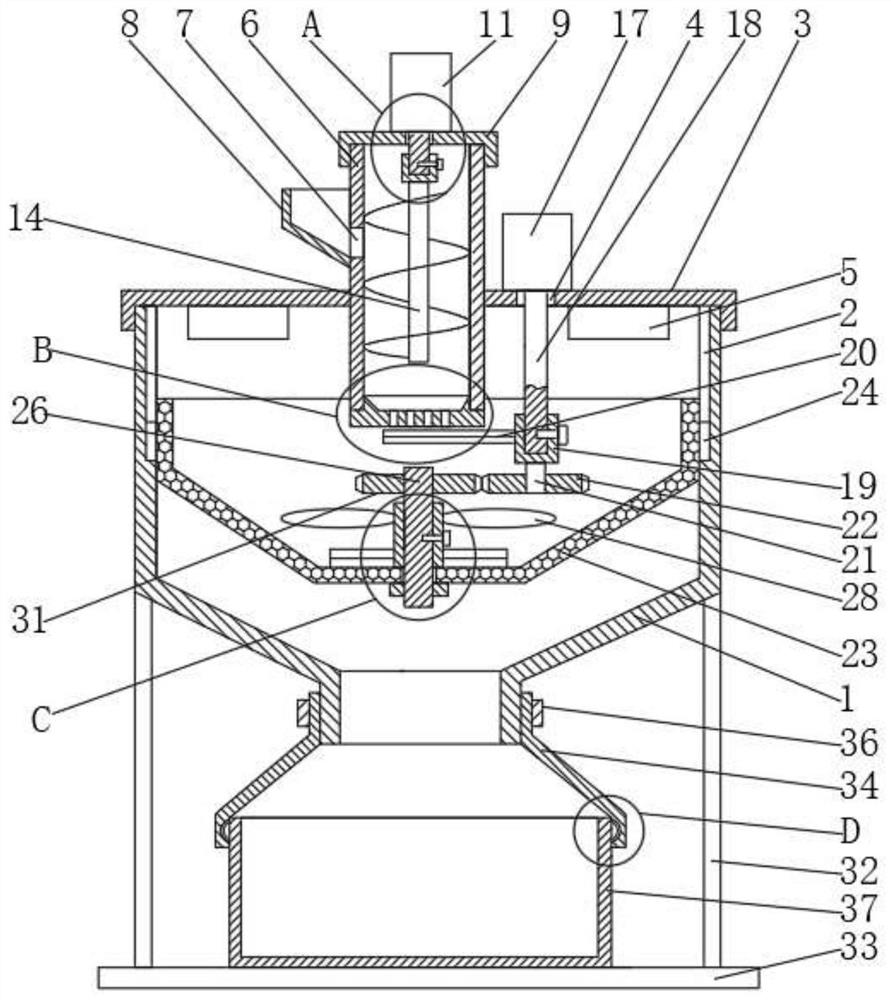

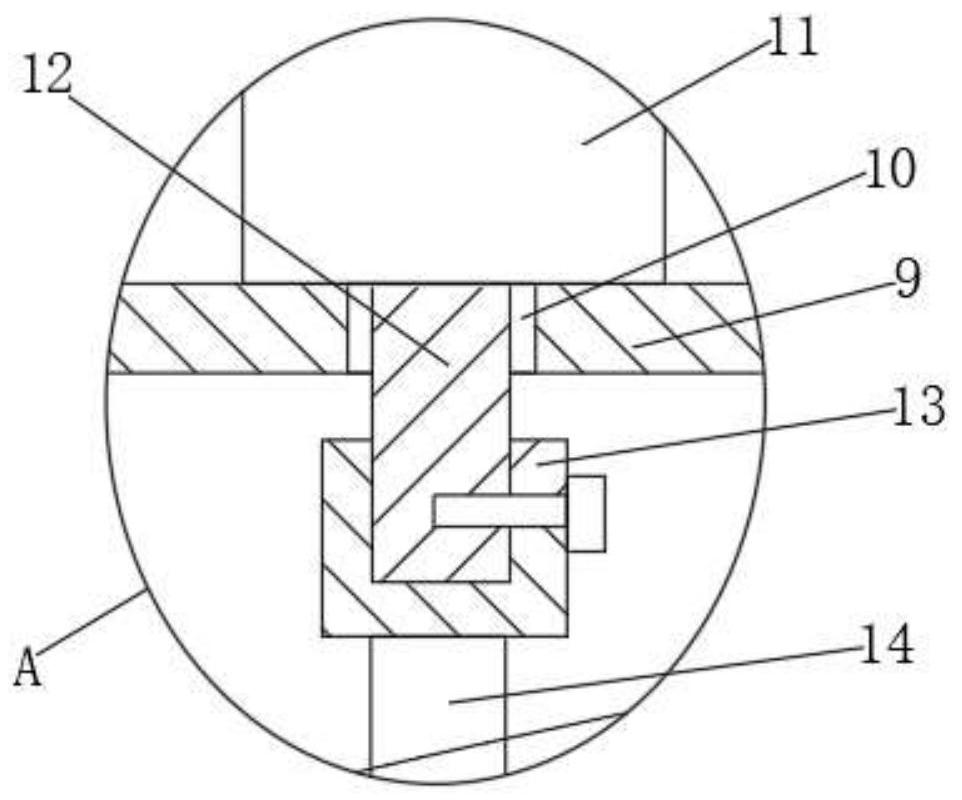

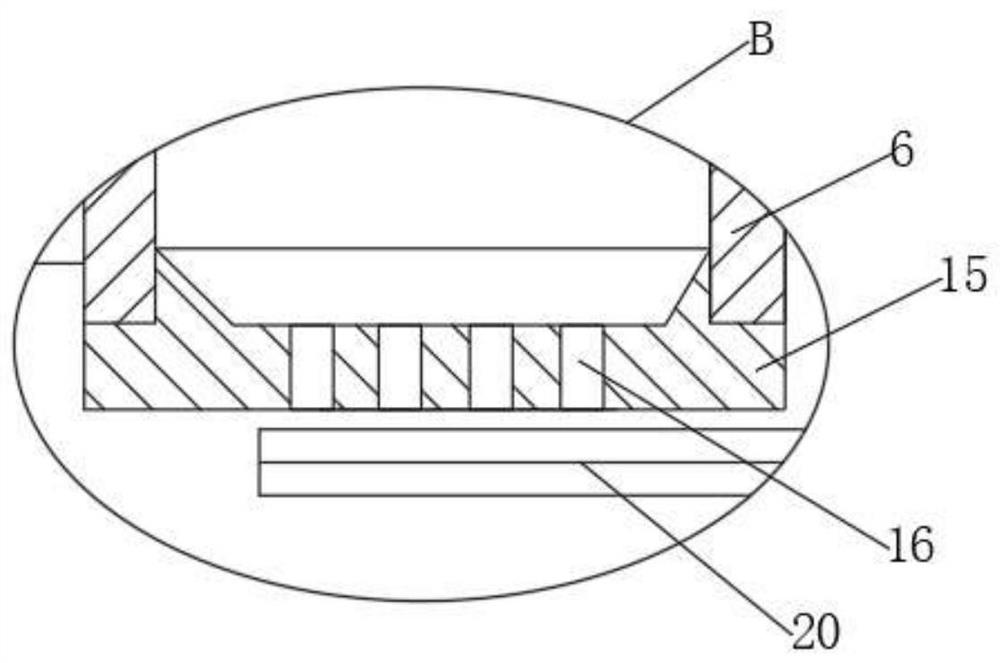

[0035] see Figure 1-8 , integrated crushing and drying equipment for pig feed processing, including a box body 1, the upper end of the box body 1 is connected with a box cover 3 through threads, the lower end of the box cover 3 is fixedly installed with a heater 5, and the box cover 3 is fixedly connected with a transmission line. Feeding barrel 6, the left side wall of feeding barrel 6 is provided with feed inlet 7, and the left side of feeding barrel 6 is fixedly connected with feeding hopper 8, and the upper end of feeding barrel 6 is connected with barrel cover 9 by screw thread, and barrel cover 9 The upper end of the first motor 11 is fixedly installed, and the lower end of the first motor shaft 12 of the first motor 11 is equipped with a first connecting sleeve 13 through bolts, and the lower end of the first connecting sleeve 13 is fixedly connected with an auger 14, and the feeding cylinder 6 The lower end is threadedly connected with an end cover 15, and a discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com