Powder pressing mold and powder pressing method thereof

A technology for pressing molds and powders. It is applied in the direction of manufacturing tools, presses, and presses for material forming. It can solve the problems of increased procurement costs and damage to the smoothness of the outer surface of the green compact. The effect of reducing the maximum size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

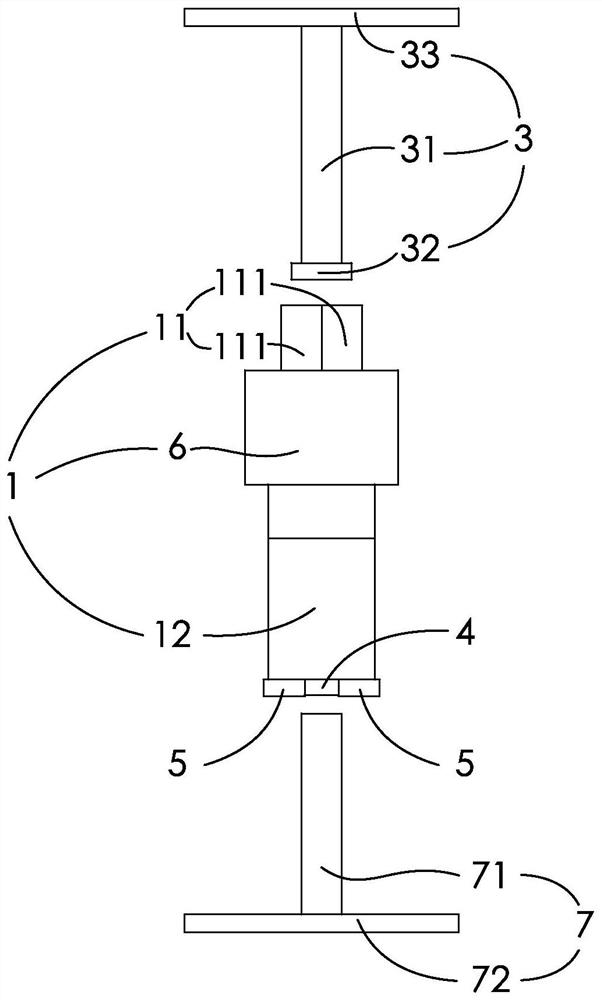

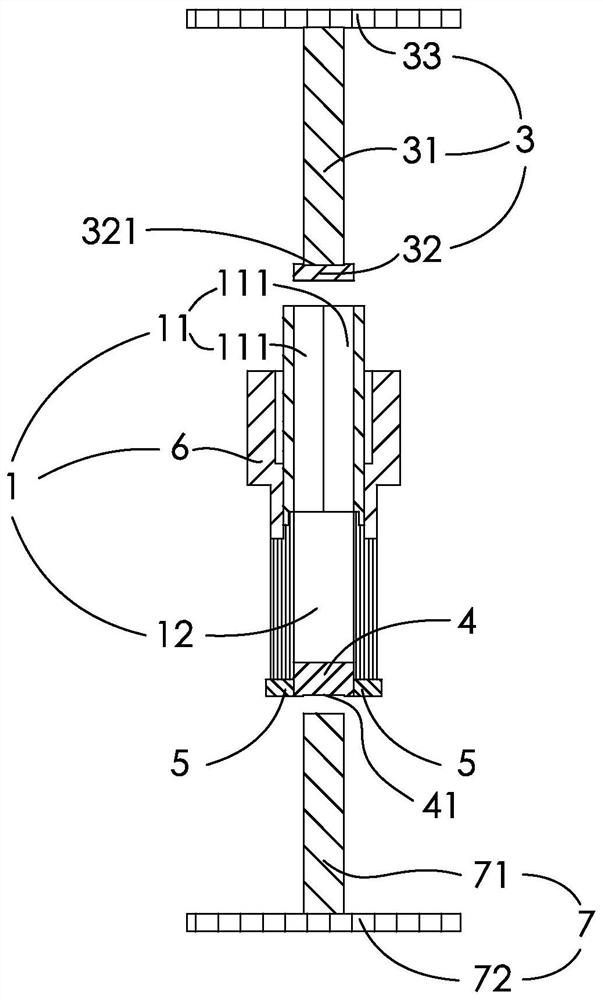

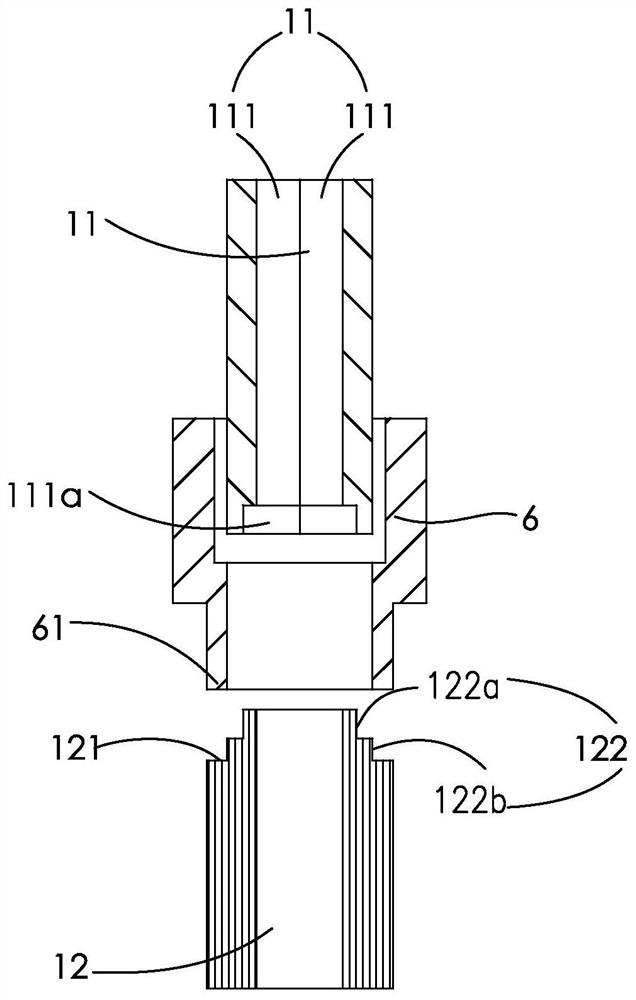

[0037] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6In the shown embodiment, a kind of powder compacting mold comprises mold cylinder 1, and mold cylinder 1 is made up of upper mold 11, lower mold 12 and peripheral cover 6, and the internal diameter of upper mold 11 and lower mold 12 is equal, and upper mold 11 and The end faces of the lower die 12 are abutted against each other; the upper die 11 is made up of two or more upper die halves 111 that can be separated radially, and a plurality of upper die halves 111 are in the shape of a fan ring, and the size of each upper die halves 111 is uniform. consistent, and each of the upper mold petals 111 is tightly fitted; the peripheral sleeve 6 is sleeved on the radially outer side of the upper mold 11, and the upper mold 11 is provided with an upper pressing rod 3, which can apply force externally. Move in the upper mold 11 and the lower mold 12 under the action, the bottom port of the lower mold 12 is pr...

Embodiment 2

[0046] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 In the shown embodiment, a kind of powder pressing mold pressing method comprises the following execution steps

[0047] A1. upper die 11, lower die 12 and peripheral cover 6 described in embodiment 1 are assembled and connected;

[0048] A2. Seal and support the bottom of the lower mold 12;

[0049] A3. Fill the powder to be pressed into the space in the upper mold and the lower mold 12 from above the upper mold until the upper and lower molds are filled with the required rated amount of powder;

[0050] A4. Use the upper pressing rod 3 described in Example 1 to extend from above the upper die 11 into the inner space of the upper die 11 and the lower die 12 containing the powder to be pressed, and the external force is applied to the upper pressing rod 3 and pushes the upper die. Depression bar 3 makes it move on the direction from upper mold 11 to lower mold 12;

[0051] A5. After the upper pr...

Embodiment approach

[0056] image 3 It shows an assembly embodiment of an upper mold, a lower mold and a peripheral sleeve. The inner side of the peripheral sleeve 6 is set to have inner diameters of different sizes. The inner diameters with different sizes can be changed by setting a stepped structure to reduce the contact between the inner side of the peripheral sleeve 6 and the outer side of the upper mold 11, and improve the convenience of taking out the upper mold or the green compact after pressing.

[0057] Figure 5 It shows an embodiment of the assembly of the device of the present invention and the molding machine during the pressing process. The molding machine includes a first upper side plate 101 and a first lower side plate 102, and the upper side of the first upper side plate 101 and the upper pressing rod 3. The top plate 33 is fixedly connected, and the positioning cylinder 103 is fixed on the first lower side plate 102. The central axis of the positioning cylinder 103 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com