High-iron aluminate cement

A technology of aluminate cement and high-speed iron, applied in the field of cement, can solve problems such as poor corrosion resistance, short setting time, and low strength, and achieve the effect of high late strength, low early strength, and large growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

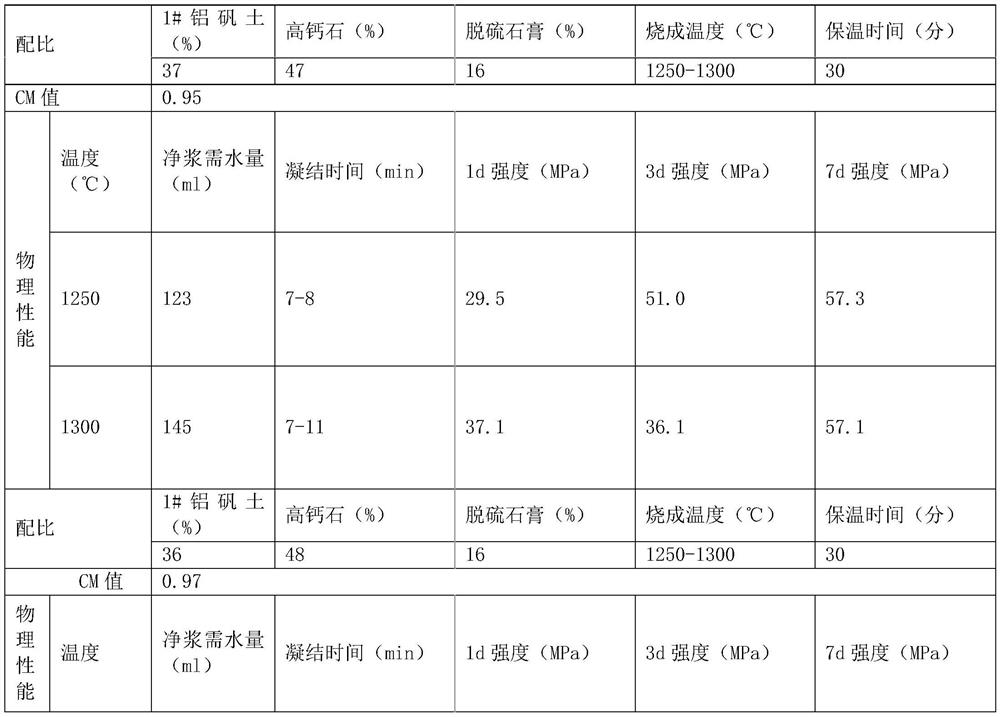

Embodiment 1

[0019] Example 1: A high-iron aluminate cement obtained by calcining bauxite in a calciner outside the kiln;

[0020] Calcium stone and desulfurized gypsum are also added to the raw material of calcined bauxite; bauxite with low aluminum content is calcined by calciner outside the kiln, and calcined stone and desulfurized gypsum are added for calcination process to obtain high iron aluminate cement Clinker, the setting time is significantly longer than that of sulphoaluminate clinker, the early strength is low, the later strength is high, and the growth rate is large. It is suitable for the production of retarded cement required by the market. At the same time, the cement has corrosion resistance and is suitable for oceans; The blank of calcining iron-aluminate clinker with calciner outside the kiln.

[0021] According to the weight fraction, 35-37 parts of bauxite, 47-49 parts of calcium stone, and 15-17 parts of desulfurized gypsum; the use of reasonable proportions is condu...

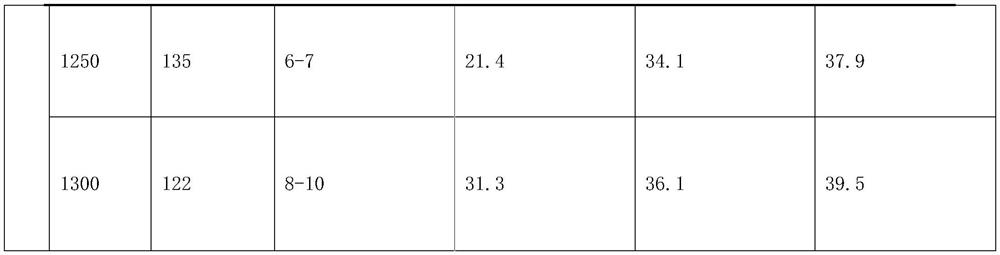

Embodiment 2

[0028] Example 2: A high iron aluminate cement obtained by calcining bauxite in a calciner outside the kiln; calcinite and desulfurized gypsum are added to the calcined bauxite raw material; calcinite and desulfurized gypsum are also added to the calcined bauxite raw material Desulfurization gypsum: calcining bauxite with low aluminum content in a calciner outside the kiln, and adding high calcium stone and desulfurization gypsum for calcining processing, the obtained high-iron aluminate cement clinker has a setting time compared with sulphoaluminate clinker Obvious side length, low early strength, high late strength, and large growth rate, suitable for the production of retarded cement required by the market. At the same time, the cement has corrosion resistance and is suitable for marine applications; it makes up for the use of calciners outside the kiln to calcinate ferroaluminate clinker Craft blank.

[0029] When the Al2O3 content in the bauxite is 48.25%, according to pa...

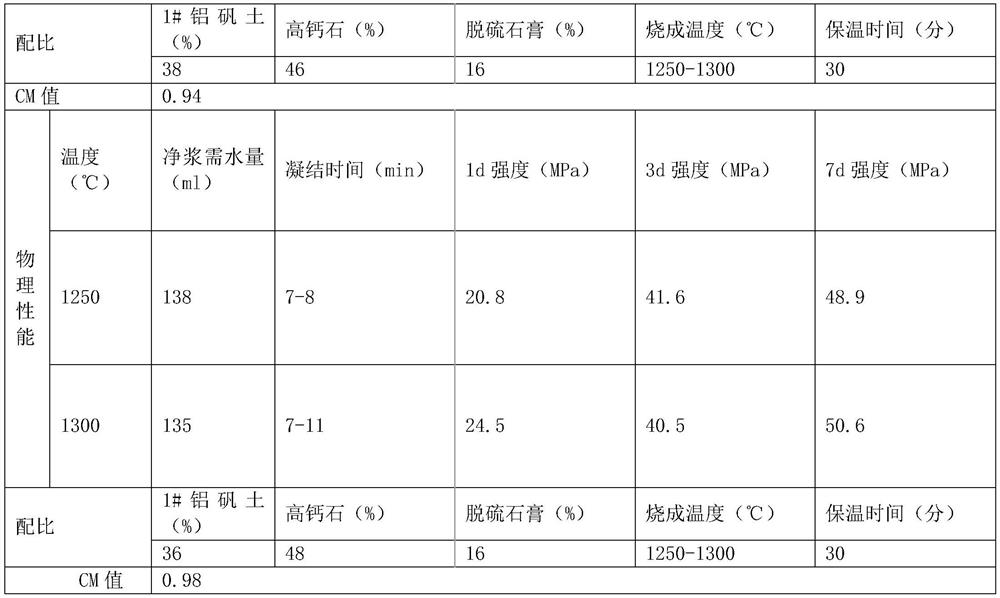

Embodiment 3

[0036] Example 3: A high iron aluminate cement obtained by calcining bauxite in a calciner outside the kiln; calcinite and desulfurized gypsum are added to the calcined bauxite raw material; calcinite and desulfurization gypsum are also added to the calcined bauxite raw material Desulfurization gypsum: calcining bauxite with low aluminum content in a calciner outside the kiln, and adding high calcium stone and desulfurization gypsum for calcining processing, the obtained high-iron aluminate cement clinker has a setting time compared with sulphoaluminate clinker Obvious side length, low early strength, high late strength, and large growth rate, suitable for the production of retarded cement required by the market. At the same time, the cement has corrosion resistance and is suitable for marine applications; it makes up for the use of calciners outside the kiln to calcinate ferroaluminate clinker Craft blank.

[0037] When the Al2O3 content in the bauxite is 48.86%, according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com