Method for preparing fracturing fluid by using fracturing flow-back fluid

A fracturing flowback fluid and fracturing fluid technology, applied in chemical instruments and methods, drilling compositions, special treatment targets, etc., can solve problems such as pollution, reduce costs, save clean water resources, and eliminate environmental problems. effect of threat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

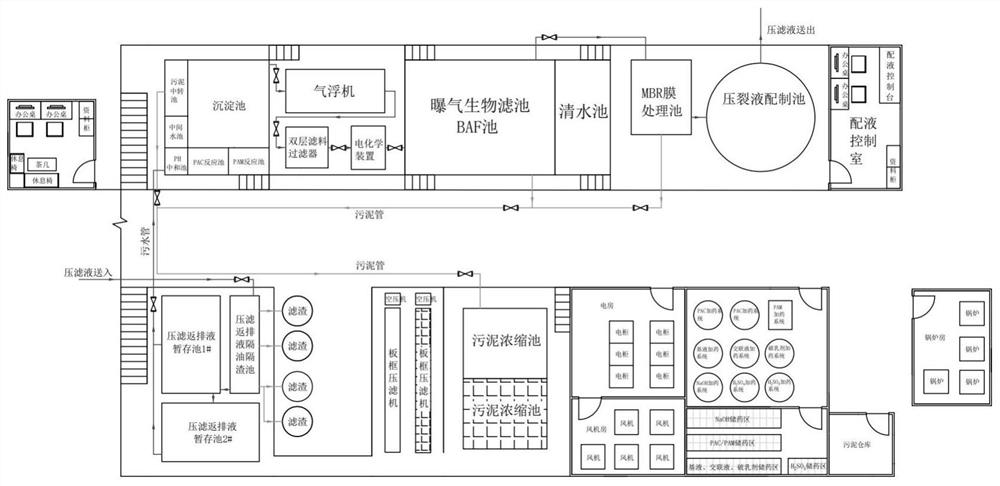

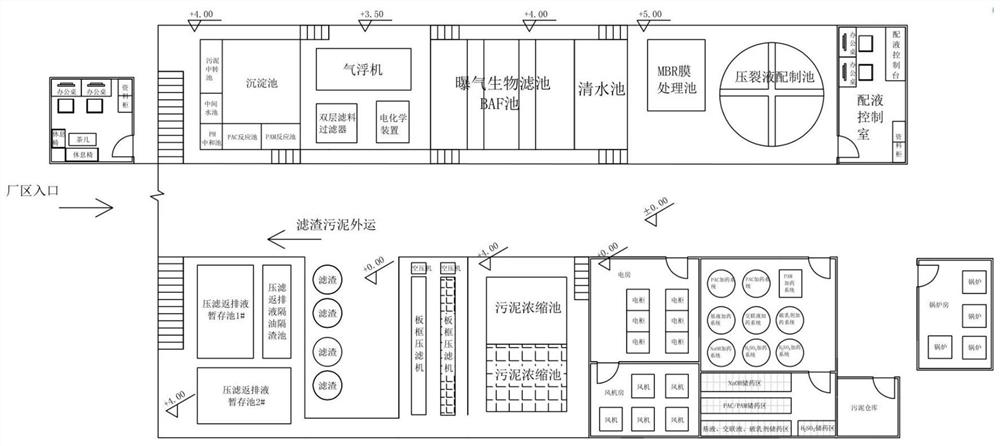

Image

Examples

specific Embodiment approach 1

[0013] Specific embodiment one: In this embodiment, a method for preparing fracturing fluid by using fracturing flowback fluid is carried out according to the following steps:

[0014] 1. Inject the fracturing flowback fluid into the sedimentation tank, add flocculant, settle for 4 to 8 hours, pump it into the air flotation machine, the air flotation reflux ratio is 20%, then perform two-stage filtration, and then enter the electrochemical device for electrolysis 80 ~100min, then enter the biological aerated filter for treatment, and then filter with the membrane bioreactor to obtain the treated fracturing flowback fluid;

[0015] 2. Mix 0.2-0.4 parts of base fluid, 0.002-0.004 parts of cross-linking agent, 0.00002-0.00005 parts of gel breaker, and 99.6-99.8 parts of fracturing flowback fluid treated in step 1. After fully stirring, fracturing fluid is obtained ; The base liquid consists of 25 parts of guar gum, 5 parts of drainage aids, 4 parts of demulsifiers, 5 parts of sod...

specific Embodiment approach 2

[0019] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, the flocculant is polyacrylamide, and the dosage of the flocculant is 40-60 mg / L. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is: the two-stage filtration in step 1 refers to passing through two double-layer filter material filters in sequence, and adding filter aid before performing one-stage filtration. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com