Device and method for continuously esterifying kitchen waste grease by using glycerol

A kind of kitchen and oily ester technology, which is applied in the direction of fatty acid esterification, petroleum industry, biofuel, etc., can solve problems such as equipment corrosion, environmental pollution, and impact on product quality, and achieve reduced desulfurization costs, low energy consumption, and increased additional costs. value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

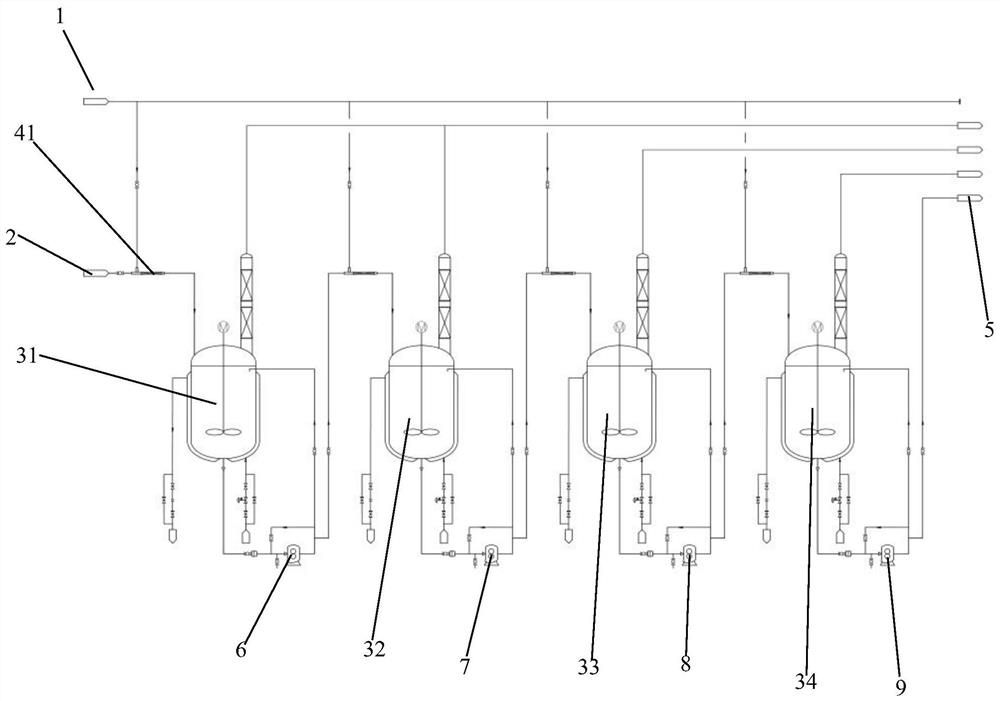

[0034] A device for continuously esterifying kitchen waste oil with crude glycerin, including crude glycerin storage tank 1, kitchen waste oil storage tank 2, multi-stage esterification kettle, multi-stage static mixer and esterified kitchen waste oil Ester storage tank 5;

[0035] The crude glycerin storage tank 1 and the kitchen waste grease storage tank 2 are respectively connected with a multistage static mixer;

[0036] The multi-stage static mixer is sequentially connected with the multi-stage esterification kettle and the storage tank 5 of kitchen waste oil and ester after esterification.

[0037] In one embodiment, the multi-stage esterification tank includes a primary esterification tank 31, a secondary esterification tank 32, a third-level esterification tank 33 and a fourth-level esterification tank 34;

[0038] Kitchen waste oil and ester storage tank 2 is successively connected with primary esterification kettle 31, secondary esterification kettle 32, tertiary es...

Embodiment 2

[0050] Utilize the device of crude glycerol to continuously esterify kitchen waste oil and fat with embodiment 1;

[0051] The method for utilizing crude glycerin to continuously esterify kitchen waste oil and fat comprises the following steps:

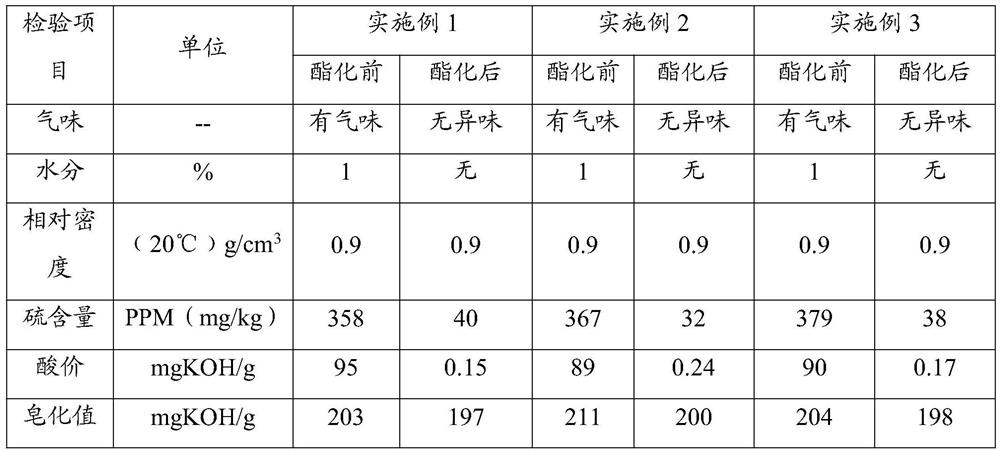

[0052] According to the mass ratio of crude glycerin and kitchen waste oil storage tank 2 as 2:100, the crude glycerin in the crude glycerin storage tank 1 and the kitchen waste oil in the kitchen waste storage tank 2 are heated to 150°C , into the primary static mixer 41 through the pipeline to mix evenly, then enter into the primary esterification kettle 31 through the pipeline, stir for 90min at a speed of 30r / min, and control the pressure to normal pressure conditions through a vacuum cooling device to obtain a mixed solution I;

[0053] According to the mass ratio of crude glycerol and mixed solution I as 2:100, the mixed solution I and crude glycerol at a temperature of 150°C are pumped into the secondary static mixer 42 throug...

Embodiment 3

[0057] Utilize the device of crude glycerol to continuously esterify kitchen waste oil and fat with embodiment 1;

[0058] The method for utilizing crude glycerin to continuously esterify kitchen waste oil and fat comprises the following steps:

[0059] According to the mass ratio of crude glycerin and kitchen waste oil storage tank 2 as 3:100, the crude glycerin in the crude glycerin storage tank 1 and the kitchen waste oil in the kitchen waste storage tank 2 are heated to 165°C , into the primary static mixer 41 through the pipeline to mix evenly, and then enter into the primary esterification kettle 31 through the pipeline and stir for 90min at a speed of 45r / min, and control the pressure to normal pressure conditions through a vacuum cooling device to obtain a mixed solution I;

[0060] According to the mass ratio of crude glycerol and mixed solution I as 3:100, the mixed solution I and crude glycerol at a temperature of 165°C are pumped into the secondary static mixer 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com