Anti-discoloration liquid detergent composition and preparation method thereof

A liquid detergent, anti-discoloration technology, applied in detergent compositions, soap detergent compositions, surface active detergent compositions, etc., can solve the problems of limited antioxidant capacity, increased rinsing times, increased water consumption, and the like, Achieve good storage stability, obvious removal effect, and inhibit the effect of darkening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

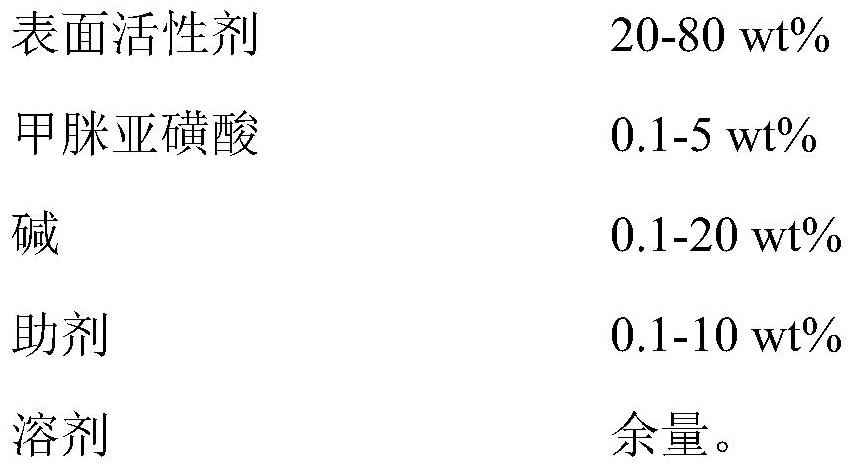

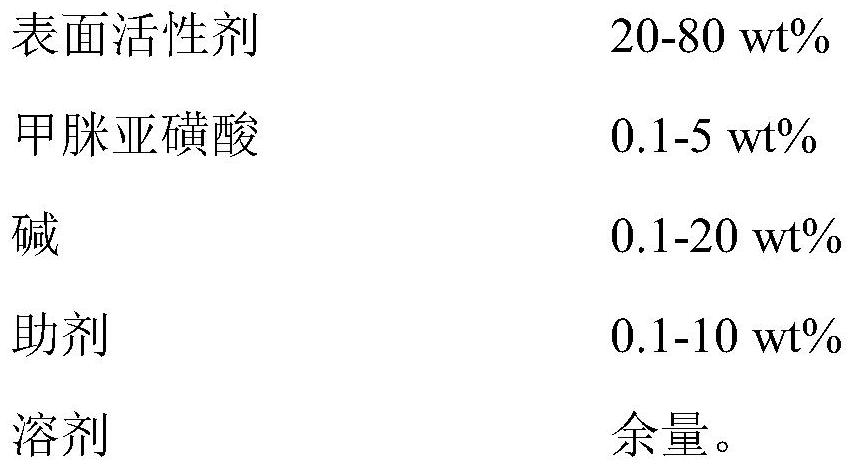

[0030] The various components and corresponding mass fractions in the detergent compositions of the examples of the present invention and the comparative examples are shown in Table 1.

[0031] Each component and corresponding mass fraction in the embodiment of table 1 and comparative example detergent composition

[0032]

[0033] The preparation method of above-mentioned embodiment 1-4 is:

[0034] S1. According to the above mass fractions, measure the weight of each component for future use;

[0035] S2. Add formamidine sulfinic acid to deionized water, stir evenly to form a solution for later use; at the same time, add monoethanolamine, triethanolamine, glycerin, propylene glycol, alkylbenzenesulfonic acid, ethoxylated fatty alcohol sulfuric acid to the reaction kettle Salt, fatty alcohol polyoxyethylene ether, saturated fatty acid, oleic acid, sodium α-alkenyl sulfonate, and essence, stirred evenly to form a mixed liquid;

[0036] S3. Add the solution into the mixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com