Step heat storage temperature control system and temperature control method based on phase change energy storage technology

A temperature control system and phase change energy storage technology, applied in heat storage equipment, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of reducing the thermal efficiency of the system, environmental heat pollution, heat waste, etc., to speed up the heat transfer of heat energy speed, improved application performance, improved performance and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

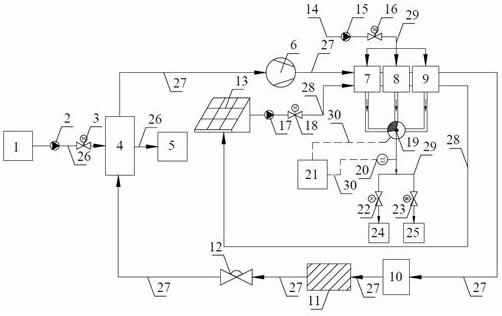

[0031] see figure 1 : A cascaded heat storage temperature control system based on phase change energy storage technology, including a high-temperature heat source 1, the high-temperature heat source 1 flows out through an evaporator 4 through a waste heat pipe 26, and the inlet and outlet of the evaporator 4 are connected through a heat exchange circulation pipe 27, The heat exchange circulation pipe 27 is sequentially connected with the compressor 6, the cascade heat storage device and the liquid storage tank 10;

[0032] It also includes a solar heat collector 13, the inlet and outlet of the solar heat collector 13 are connected through a heat collection circulation pipe 28, and the heat collection circulation pipe 28 is connected with a cascade heat storage device;

[0033] It also includes a normal temperature water source 14, and the normal temperature water source 14 flows out through the heating circulation pipe 29 through the cascade heat storage device and the equipme...

Embodiment 2

[0050] Heat storage process 1 and heat storage process 2 can be carried out simultaneously. Specifically:

[0051] Turn off booster pump 2 15, electric valve 2 16, circulating water pump 17, electric valve 3 18, electric valve 4 22, electric valve 5 23, turn on booster pump 1 2, electric valve 1 3, and turn on circulating water pump 17 and electric valve Three 18,

[0052] The high-temperature heat source 1 and the refrigerant exchange heat in the evaporator 4, the heat released by the high-temperature heat source 1 becomes low-temperature waste heat 5, and the gas-liquid two-phase refrigerant absorbs heat in the evaporator and becomes a low-temperature and low-pressure gas, which enters the compressor 6 The temperature rises and the pressure becomes a high-temperature and high-pressure gas. The high-temperature and high-pressure refrigerant gas enters the cascade heat storage device for condensation and heat release. At the same time, the high-temperature and high-pressure w...

Embodiment 3

[0054] A cascaded heat storage and temperature control system based on phase change energy storage technology mentioned in the present invention differs from Embodiment 1 in that:

[0055] The cascade heat storage device is divided into four heat storage bodies. In the four heat storage bodies, phase change materials with a phase change temperature of 90°C are used, phase change materials with a phase change temperature of 70°C, and a phase change temperature of 50°C are used. The phase change material, the phase change material with a phase change temperature of 30°C.

[0056] Compared with Example 1, this cascade heat storage device adds a heat storage body, which adopts the technology of placing phase change materials with different phase change temperatures in series, which helps to ensure that the temperature difference between the phase change material and the heat exchange fluid is more uniform , improve heat transfer efficiency.

[0057] A cascade heat storage and tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com