Photoelectric liquid level sensor

A liquid level sensor, photoelectric technology, applied in the direction of buoy liquid level indicator, liquid level indicator, instrument, etc., can solve the problems of liquid level sensor switch state switching false alarm, poor protection, reed switch damage, etc., to achieve The production and transportation process is stable and reliable, the detection signal is stable and accurate, and the effect of large difference between high and low voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

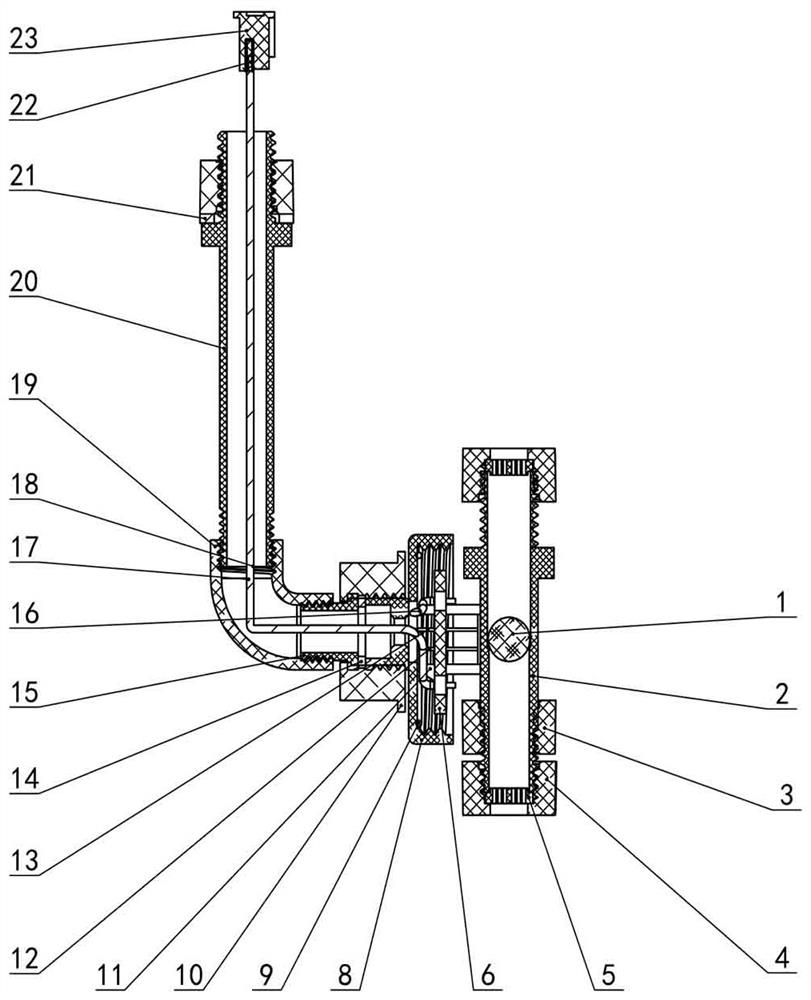

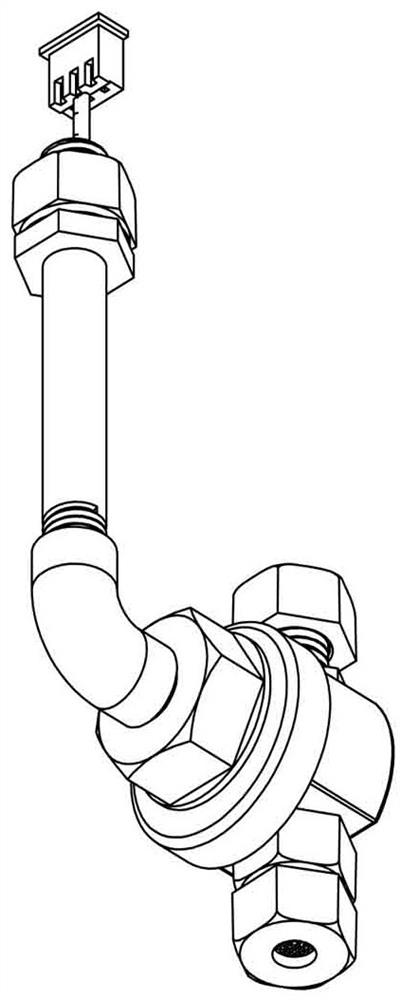

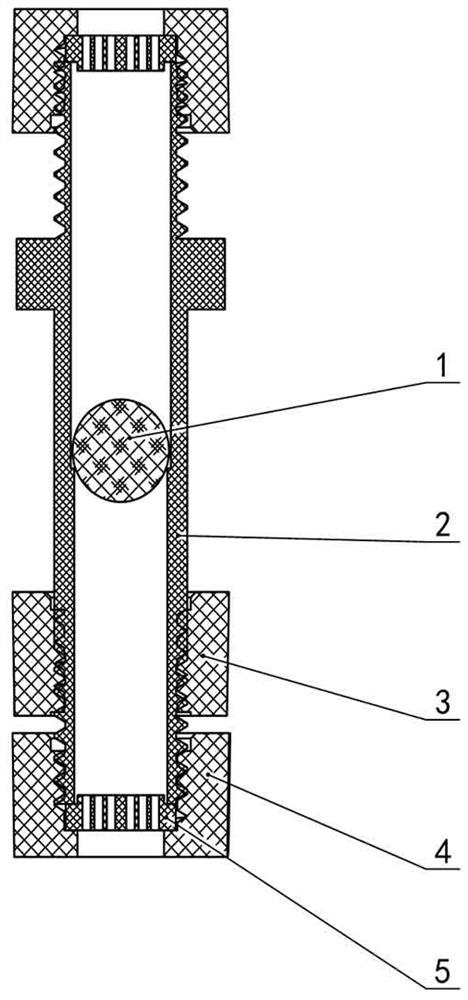

[0044] The present invention provides a photoelectric liquid level sensor. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

[0045] Such as Figure 1-27 As shown, the present invention includes a float assembly, a photoelectric control assembly, and an installation assembly. The float assembly includes a float 1, a float guide rod 2, a nut A3, a nut B4 and a filter screen 5; the photoelectric control assembly is fixed on On the float guide rod 2 in the float assembly, the photoelectric control assembly includes a transparent casing 7, a PCB board 6, a light pipe bracket 11, an infrared emitting tube 12, an infrared receiving tube 13, an O-shaped sealing ring 9, and a base 8 , nut C10, wire I16, wire II17, wire III18, flat washer ①14, connector 15; the installation assembly is connected to the connector 15, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com