Burr detection method, device and equipment and storage medium

A detection method and detection device technology, which are applied in measurement devices, optical testing flaws/defects, image data processing, etc., can solve problems such as short circuit of positive and negative electrodes of batteries, explosion, and cumbersome detection process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

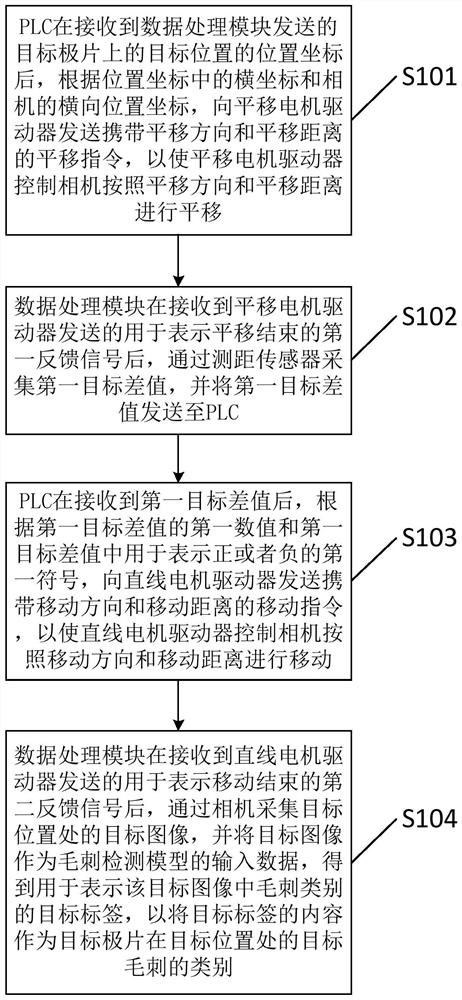

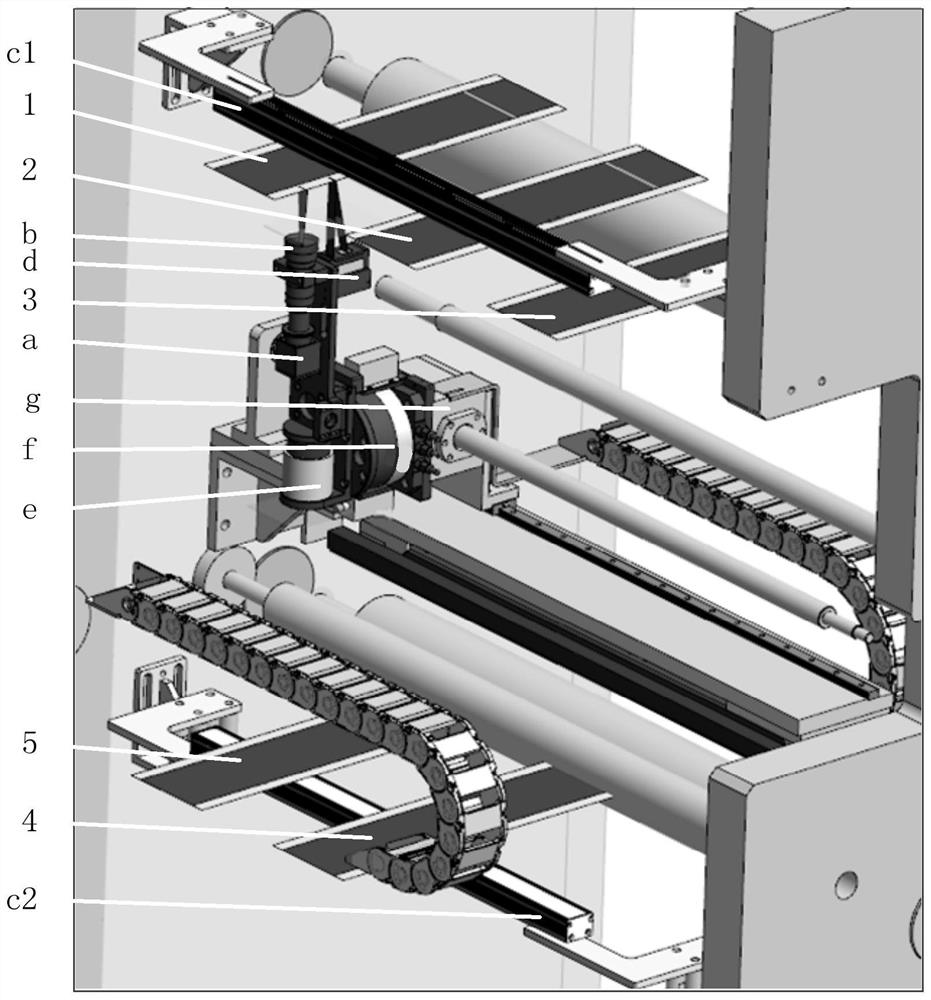

[0054] figure 1 A flow chart of a glitch detection method provided by Embodiment 1 of the present application is shown, as shown in figure 1 As shown, the burr detection method is applied to a burr detection device, and the burr detection device includes: a camera equipped with a telecentric lens, a distance measuring sensor, a data processing module, a PLC and a motor driver, wherein the data processing module is connected with the The camera, the distance measuring sensor and the PLC are electrically connected, the PLC is electrically connected to the motor driver, and the motor driver includes a linear motor driver, a translation motor driver and a rotary motor driver; the glitch detection method includes the following steps:

[0055] Step S101: After the PLC receives the position coordinates of the target position on the target pole piece sent by the data processing module, according to the abscissa in the position coordinates and the lateral position coordinates of the ca...

Embodiment 2

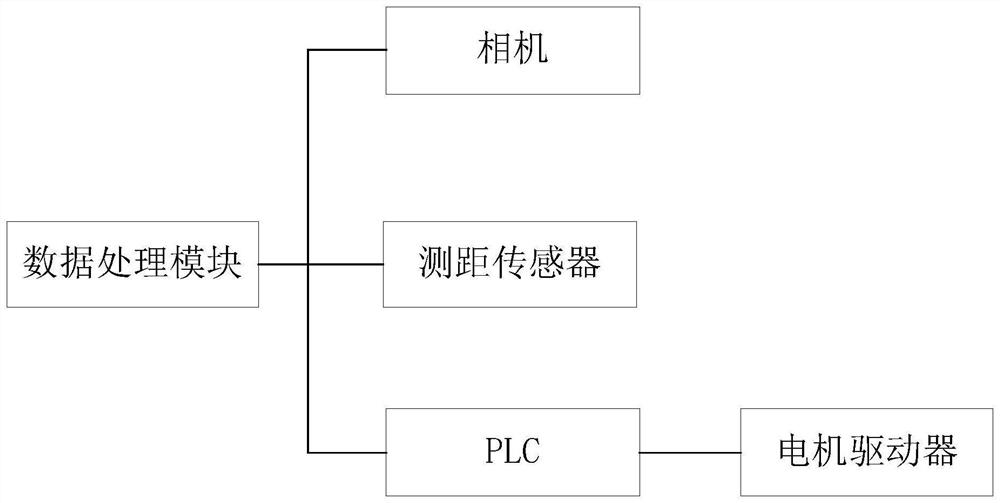

[0105] figure 2 A schematic structural diagram of a burr detection device provided in Embodiment 2 of the present application is shown, as shown in figure 2 As shown, the burr detection device includes: a camera equipped with a telecentric lens, a distance measuring sensor, a data processing module, a programmable logic controller PLC and a motor driver, wherein the data processing module is connected to the camera, the The ranging sensor is electrically connected to the PLC, and the PLC is electrically connected to the motor driver, and the motor driver includes a linear motor driver, a translation motor driver and a rotary motor driver;

[0106] The PLC is configured to, after receiving the position coordinates of the target position on the target pole piece sent by the data processing module, according to the abscissa in the position coordinates and the lateral position coordinates of the camera, move the The driver sends a translation command carrying a translation dire...

Embodiment 3

[0128] The embodiment of the present application also provides a computer device 400, Figure 4 It shows a schematic structural diagram of a computer device provided by Embodiment 3 of the present application, as shown in Figure 4 As shown, the device includes a memory 401, a processor 402, and a computer program stored on the memory 401 and operable on the processor 402, wherein the above-mentioned glitch detection method is implemented when the above-mentioned processor 402 executes the above-mentioned computer program.

[0129] Specifically, the above-mentioned memory 401 and processor 402 can be general-purpose memory and processor, which are not specifically limited here. When the processor 402 runs the computer program stored in the memory 401, it can execute the above-mentioned glitch detection method, which solves the problem of prior art The problem of large manual workload.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com