Cold-brewed green tea and processing technology thereof

A processing technology and green tea technology, applied in the field of cold-brewed green tea and its processing technology, can solve the problems of high cost, high production condition requirements, low cell fragmentation rate, etc., and achieve the production cost reduction, the technology is easy to master, and the production process is simplified. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

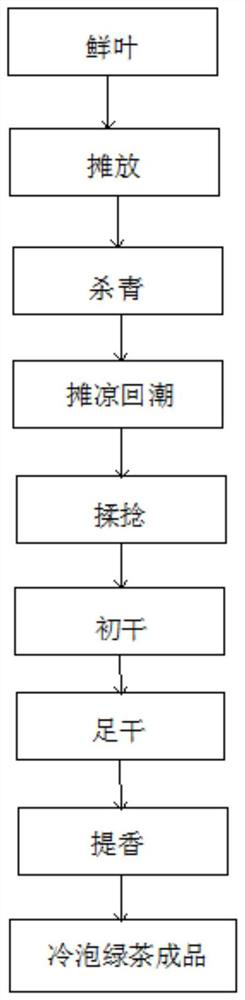

[0042] Fresh leaves→spreading→cooking→cooling and regaining moisture→kneading→first drying→full drying→increasing fragrance→cold-brewed green tea finished product. Such as figure 1 shown.

[0043] A kind of production technology of cold-brewed green tea, this production technology comprises successively:

[0044] Step 1: Pick fresh leaves with one bud and one leaf suitable for making cold brewed green tea;

[0045] Step 2: Spread the fresh leaves in the green tank for spreading, the spreading thickness is 5cm, the spreading time is 4 hours, and the air is blown once every 3 hours for 10 minutes, and the weight loss of spreading is about 8%;

[0046] Step 3: carry out de-enzyming treatment on the spread leaves, the de-enzyming equipment selects 80 type drum de-enzyming machine, the temperature of the tea inlet of the de-enzyming machine is 230°C, the middle part is 320°C, the tea outlet is 160°C, and the moisture content of the de-enzyme leaves is not higher than 58%;

[004...

Embodiment 2

[0054] Fresh leaves→spreading→cooking→cooling and regaining moisture→kneading→first drying→full drying→increasing fragrance→cold-brewed green tea products.

[0055] A kind of production technology of cold-brewed green tea, this production technology comprises successively:

[0056] Step 1: Pick fresh leaves with one bud and one leaf suitable for making cold brewed green tea;

[0057] Step 2: Spread the fresh leaves in the green trough for spreading, the spreading thickness is 10cm, the spreading time is 12 hours, and the air is blown once every 3 hours for 10 minutes, and the weight loss of spreading is about 8%;

[0058] Step 3: carry out de-enzyming treatment on the spread leaves, the de-enzyming equipment selects 80 type drum de-enzyming machine, the temperature of the tea inlet of the de-enzyming machine is 260°C, the middle part is 350°C, the tea outlet is 180°C, and the water content of the de-enzyme leaves is about 58%;

[0059] Step 4: Thinly spread the green leaves o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com