Intelligent closed mold lead ingot continuous casting system

A lead ingot, intelligent technology, applied in the field of intelligent closed mold lead ingot continuous casting system, can solve the problems of large contact area between lead liquid and air, easy generation of lead vapor, and large air pollution, so as to reduce the production of oxide slag and lead ingots. Stable and reliable quality, the effect of reducing air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

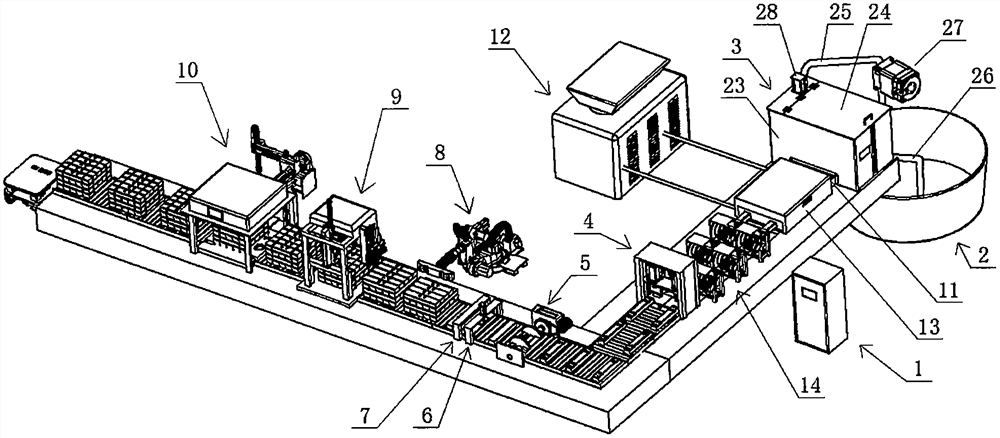

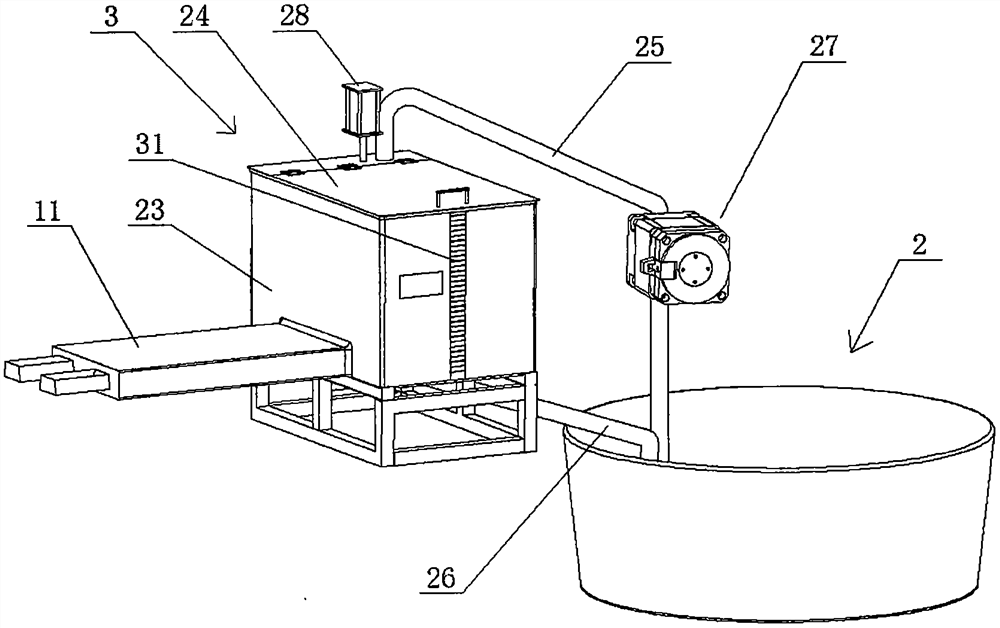

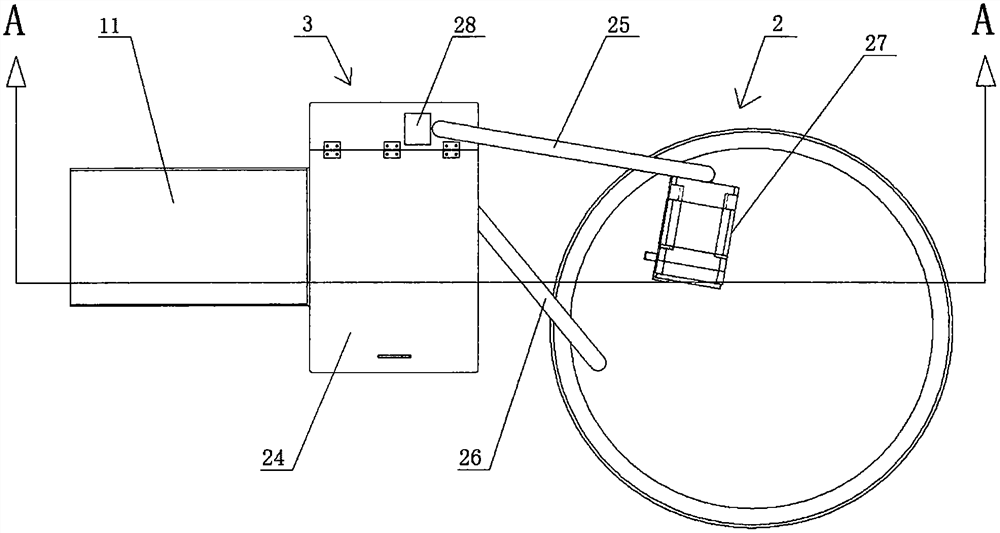

[0029] Example: such as Figure 1 to Figure 10 As shown, an intelligent closed mold lead ingot continuous casting system includes an automatic conveyor and a control cabinet 1, and a lead melting furnace 2, a liquid storage tank 3, an ingot forming device, a cutting device 4, Lead ingot turning device 5, lead ingot marking device 6, lead ingot anti-oxidation spray device 7, palletizing robot 8, automatic bundling machine 9, automatic weighing and marking machine 10;

[0030] Described ingot molding device comprises two lead ingot molds 11 that are arranged side by side with liquid storage tank 3 fully closed connections, and above lead ingot mold 11 is provided with the crystallizer 13 that cooling source is provided by cooling machine 12, each from lead The lead bars drawn from the ingot mold 11 outlets are all equipped with an independent traction forming mechanism.

[0031] Described traction forming mechanism comprises 3 traction rollers 15, and each traction roller 15 al...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap