Sugarcane head and tail removing equipment for food processing

A food processing and sugarcane technology, which is applied in the field of sugarcane head and tail removal equipment for food processing, can solve the problems of sugarcane head and tail removal, time-consuming and labor-intensive work, and low work efficiency, so as to achieve high safety, improve work efficiency, and avoid accidental injuries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

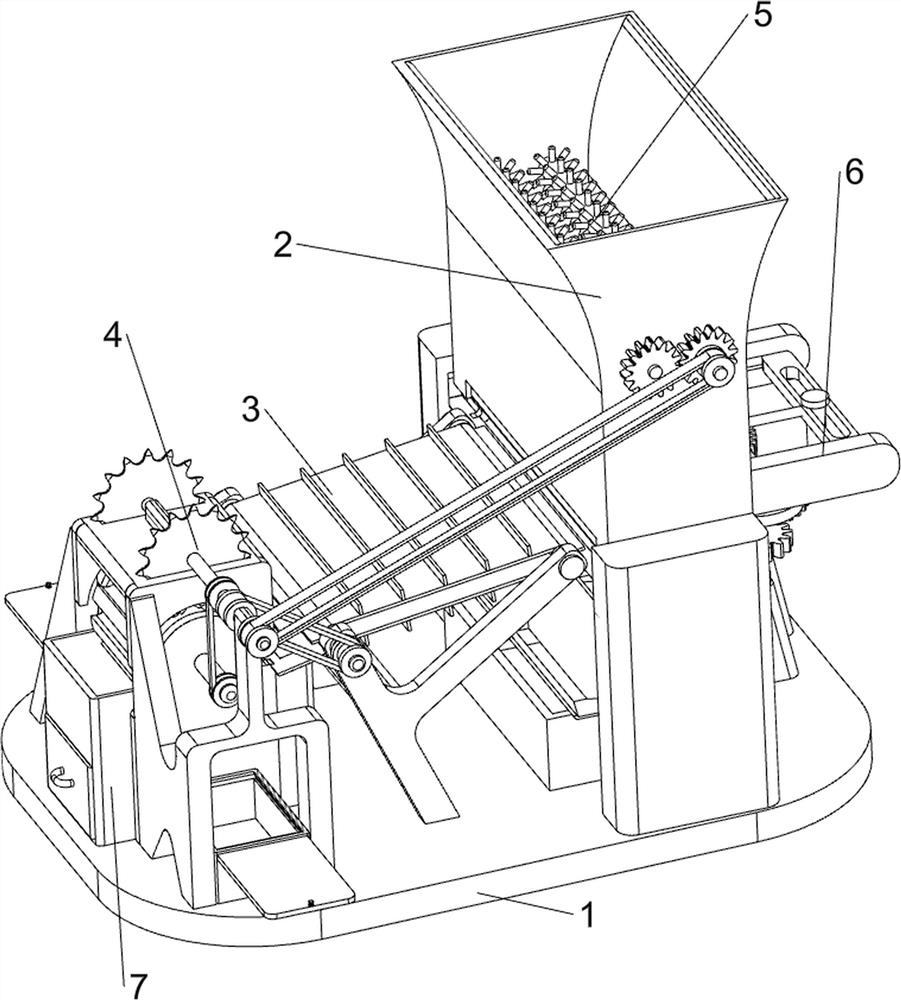

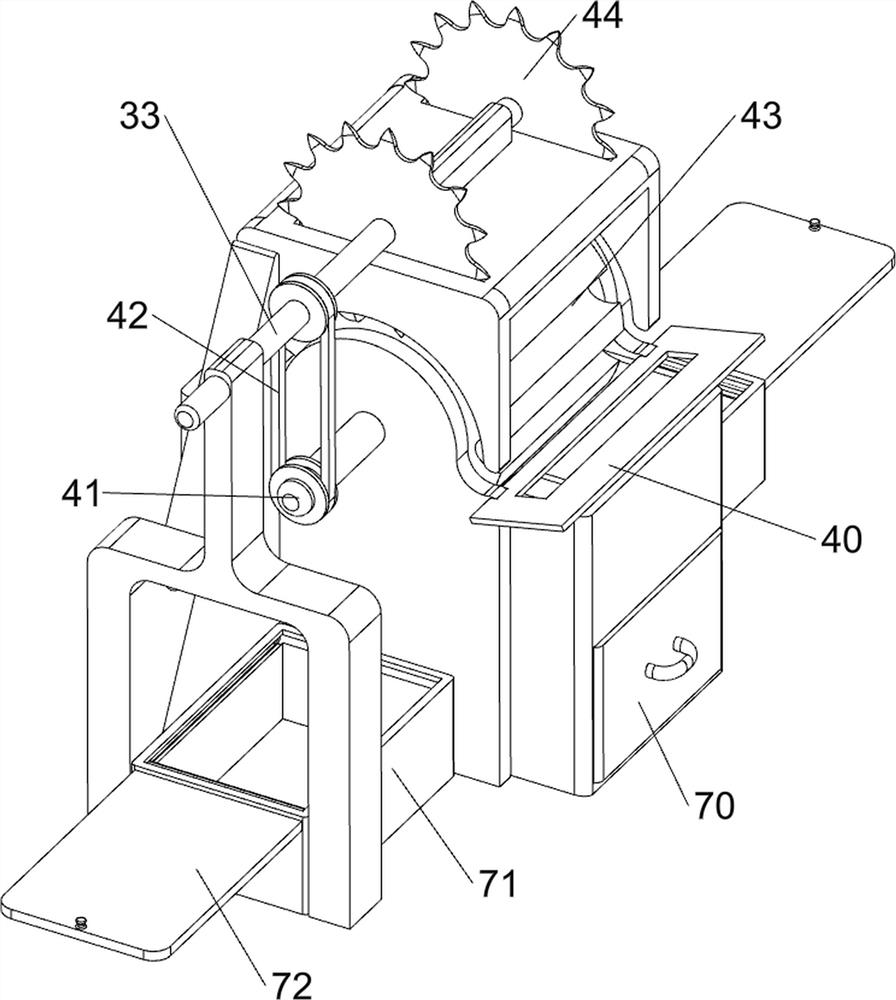

[0065] A kind of equipment for removing sugarcane heads and tails for food processing, such as figure 1 , figure 2 , image 3 with Figure 4 As shown, it includes a bottom plate 1, a feeding mechanism 2, a transmission mechanism 3 and a cutting mechanism 4. The top right side of the bottom plate 1 is provided with a feeding mechanism 2, the top middle side of the bottom plate 1 is provided with a transmission mechanism 3, and the top left side of the bottom plate 1 is provided with a A cutting mechanism 4 is arranged, and the cutting mechanism 4 includes a blanking ramp 40, a fifth drive shaft 41, a third belt 42, a material distribution drum 43 and a saw blade 44, and the left side of the upper part of the bottom plate 1 is provided with a blanking ramp 40, the bottom plate 1. The upper part is left rotating and has a fifth transmission shaft 41. The fifth transmission shaft 41 is provided with a distribution roller 43. A third belt 42 is provided between the fifth transmi...

Embodiment 2

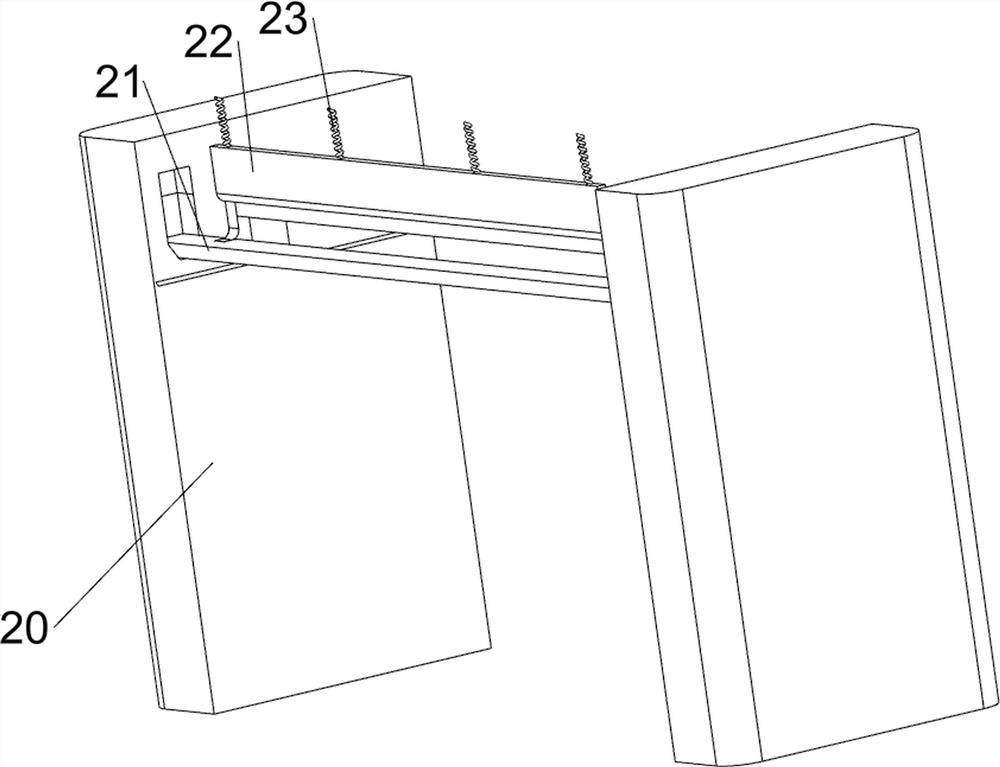

[0070] On the basis of Example 1, such as Figure 4 , Figure 5 and Image 6 As shown, a cleaning mechanism 5 is also included. The cleaning mechanism 5 includes a sixth transmission shaft 50, a first spur gear 51 and a brush roller 52. Both the transmission shaft 50 and the front side of the first transmission shaft 31 are provided with a first spur gear 51 , the first spur gears 51 mesh with each other, and the sixth transmission shaft 50 and the first transmission shaft 31 are both provided with a brush roller 52 .

[0071] When the first transmission shaft 31 rotates, it drives the first straight gear 51 and the sixth transmission shaft 50 to rotate, thereby driving the brush cylinder 52 to rotate, so that the brush cylinder 52 scrubs the sugarcane in the support seat 20, when the first transmission When the shaft 31 stops rotating, the above-mentioned rotations all stop.

[0072] Also include push mechanism 6, push mechanism 6 includes the seventh transmission shaft 60...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap