Offshore wind-resistant environment-friendly oil removal equipment

An equipment and environmental protection technology, applied in general water supply saving, open water surface cleaning, ships and other directions, can solve the problems of reducing the percentage of oil absorption, increasing the time of oil absorption, oil leakage, etc., to reduce drag resistance, easy to carry, reduce volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples or drawings are used to illustrate the present invention, but not to limit the scope of the present invention.

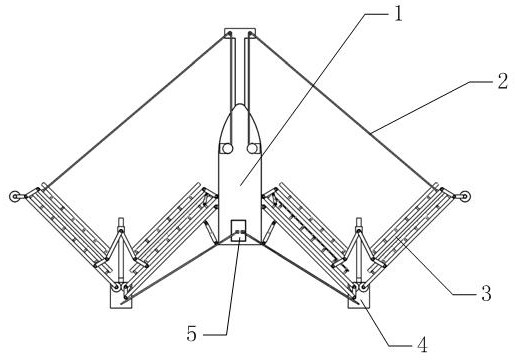

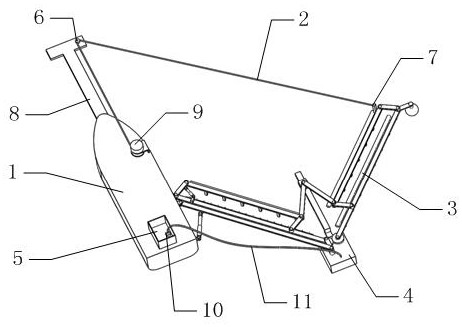

[0041] Such as figure 1 As shown, it includes a hull 1, a stay rope 2, an oil suction device 3, a collection box 5, a pump 10, and an oil suction pipe 11, wherein two oil suction devices 3 are symmetrically installed on both sides of the hull 1 rear.

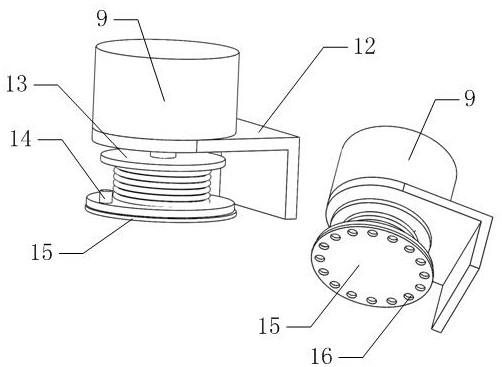

[0042] Such as figure 2 , 4 As shown, the above-mentioned oil suction device 3 includes an extraction device 4, a floating ball 17, a front oil collecting arm 18, a rear oil collecting arm 22, a second swing rod 24, a gear 26, a first hydraulic rod 28, a second hydraulic rod 29, a floating Rod 30, the fourth swing rod 31, mounting rod 32, connecting rod 33, partition 34, ball cover 35, elastic bag 36, air pipe 38, wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com