A cathode and anode bed regeneration waste acid and alkali water treatment device for chlor-alkali industry

A water treatment device, a technology of the chlor-alkali industry, applied in water/sewage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems affecting treatment and achieve the effect of promoting high-speed growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

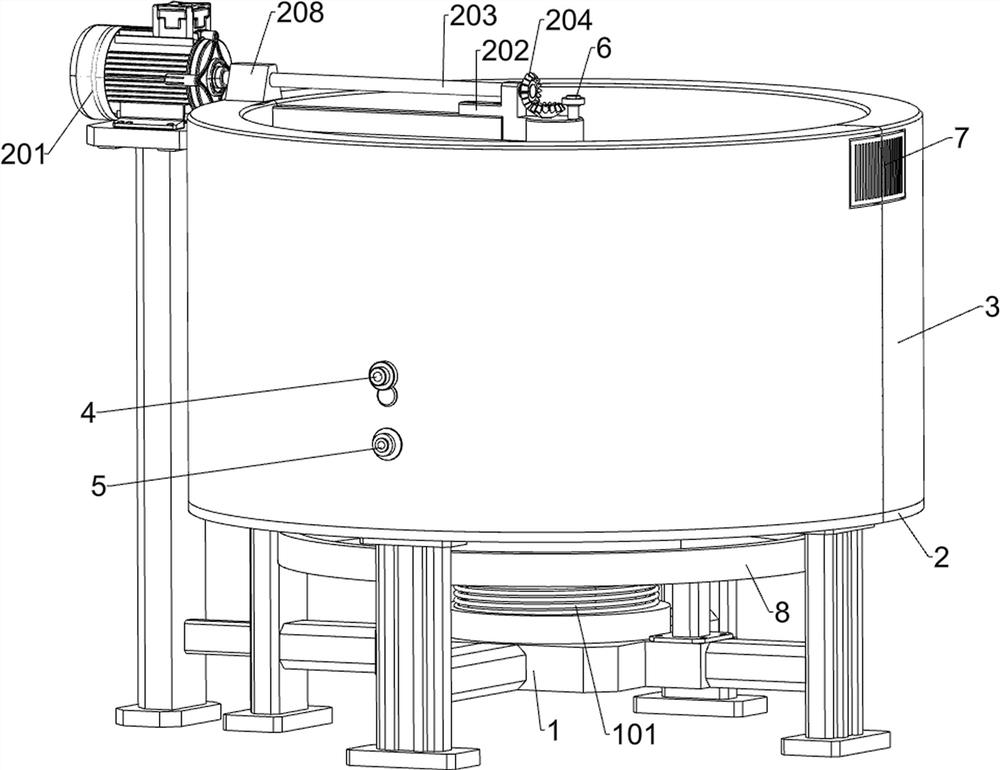

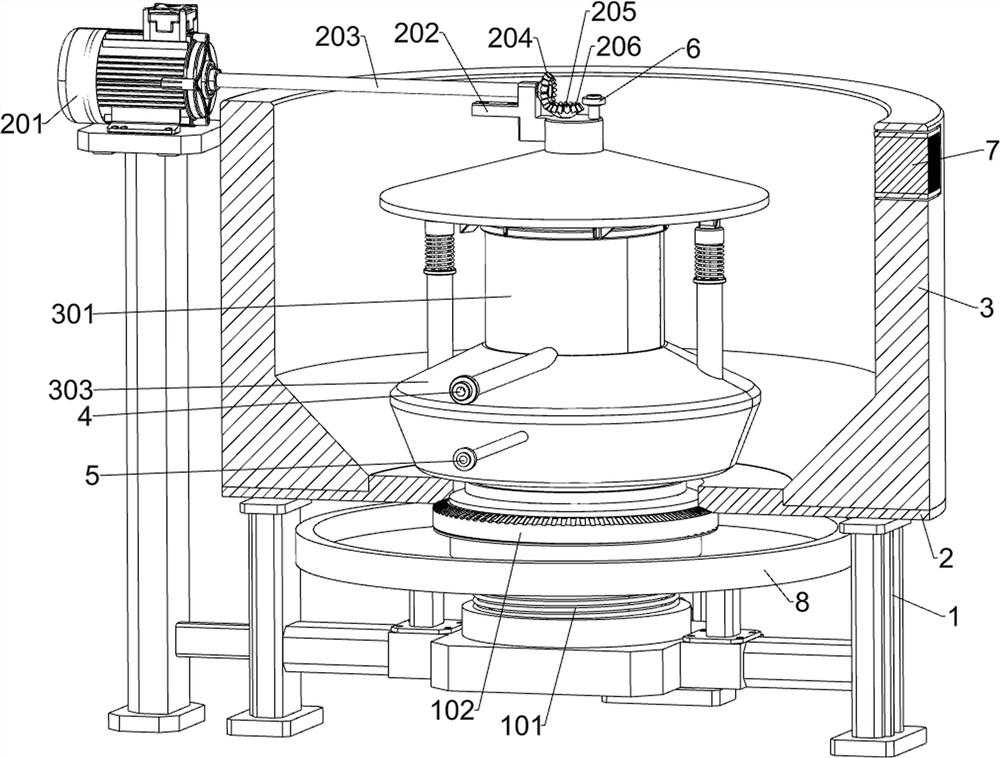

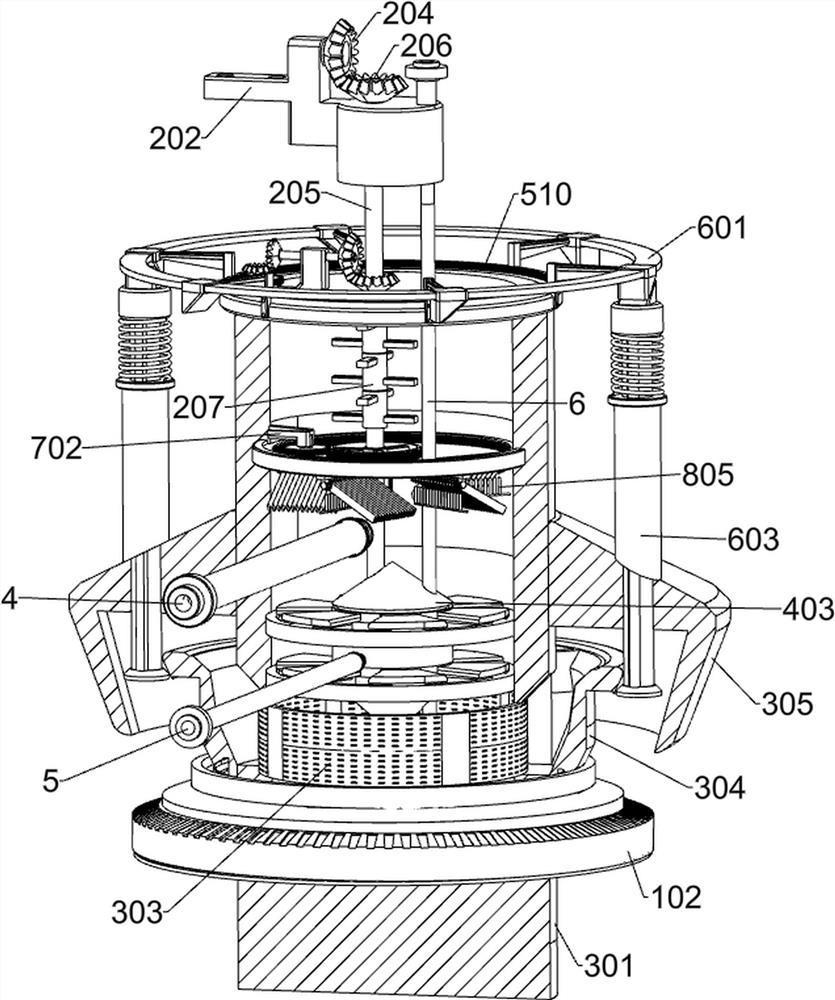

[0035] A kind of anode and cathode bed regeneration waste acid and alkali water treatment device for chlor-alkali industry, such as Figure 1-Figure 5 As shown, it includes collection assembly, stirring assembly, middle sleeve assembly, steam distribution assembly, lifting control assembly, pressurized flushing assembly, main support 1, bottom plate 2, reaction bulkhead 3, mixed liquid delivery pipe 4, sea salt delivery Pipe 5, steam conveying pipe 6, overflow net 7 and collecting pan 8; the top bolt of main support 1 is connected with bottom plate 2; the upper surface of bottom plate 2 is welded with reaction bulkhead 3; the lower part of the front wall of reaction bulkhead 3 is connected There is a mixed liquid delivery pipe 4; the front wall of the reaction bulkhead 3 is connected with a sea salt delivery pipe 5, and the sea salt delivery pipe 5 is located below the mixed solution delivery pipe 4; the upper part of the right wall of the reaction bulkhead 3 is fixed with an o...

Embodiment 2

[0051] On the basis of Embodiment 1, a rotating assembly is also included, such as Figure 2-Figure 4 ,as well as Figure 12 and Figure 13 As shown, the inner wall of the isolation cylinder 301 is provided with a rotating assembly, and the rotating assembly includes a fourth spur gear 701, a fourth fixed frame 702, a fifth spur gear 703, a fourth annular slider 704 and a fourth annular tooth plate 705; The fourth spur gear 701 is fixedly connected to the top of the second rotating shaft 205; the fourth fixed frame 702 is welded on the upper left part of the inner side wall of the isolation cylinder 301; The gear 703 meshes with the fourth spur gear 701; the upper part of the inner side wall of the isolation cylinder 301 is slidably connected with a fourth annular slider 704; the fourth annular slider 704 is located on the lower side of the fourth fixed frame 702; the inner side of the fourth annular slider 704 A fourth annular tooth plate 705 is fixedly connected to the wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com