Method for realizing laser glass edge covering by using ultrashort pulse laser

A technology of ultra-short pulse laser and laser glass, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc. It can solve the problems of low bonding strength, complex heat treatment process, shedding, etc. The effect of good rate matching and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

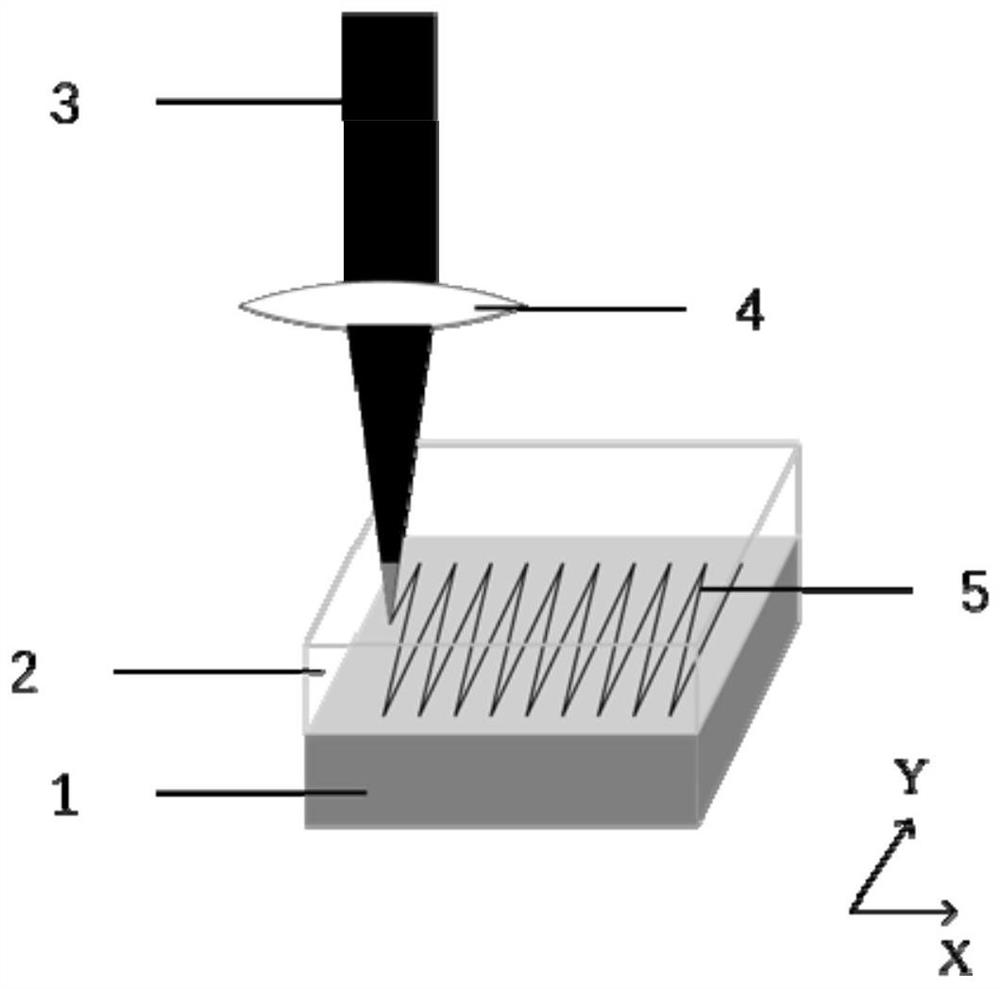

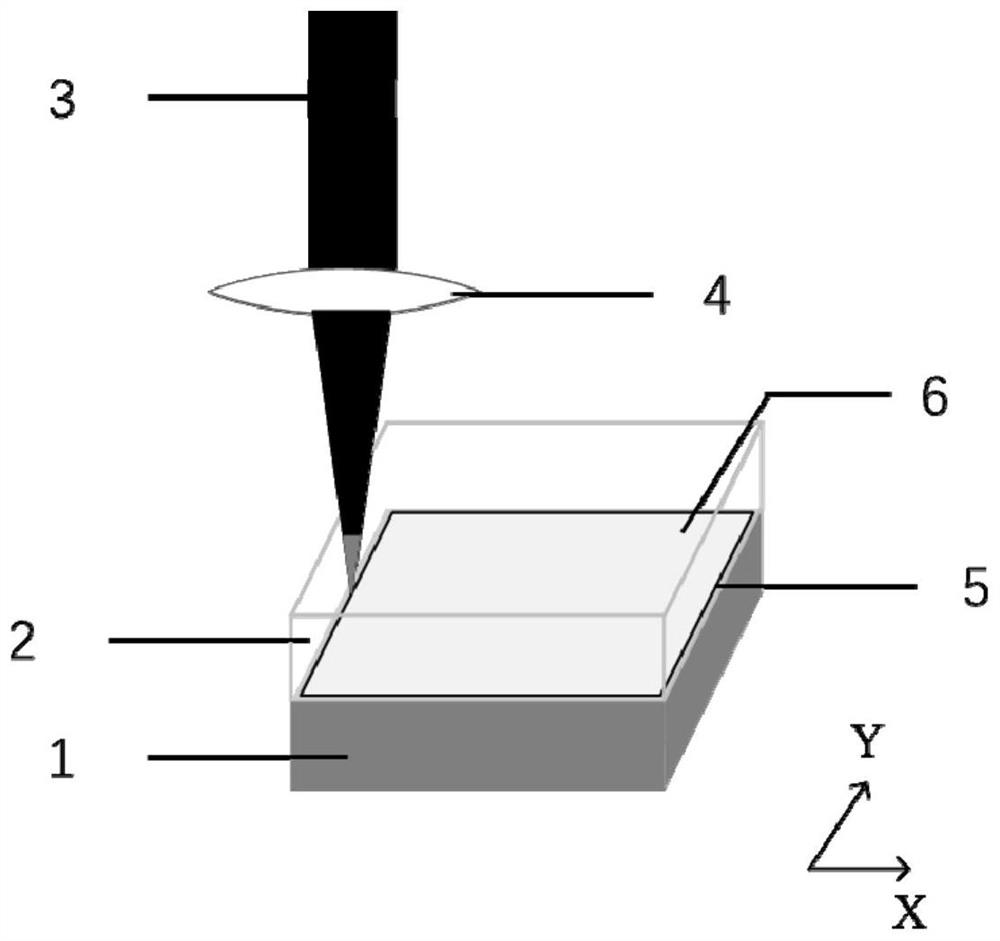

[0036] refer to figure 1 A method for realizing laser glass edge wrapping by using an ultrashort pulse laser, comprising the following steps:

[0037] 1) According to the refractive index n of the laser glass 1 1 And the thermal expansion coefficient selects the edge glass 2: the thermal expansion coefficient difference between the edge glass 2 and the laser glass 1 is less than 2%, and the refractive index of the edge glass 2 and the laser glass 1 in the operating laser band are respectively n 2 , n 1 , both of which satisfy n 2 >n 1 , and the refractive index difference is less than 0.005.

[0038] 2) Processing the selected laser glass 1 and edge glass 2 . Grinding and polishing the side of the glass to be edged requires the overall finish to be grade 2, and the surface profile is better than λ / 3, where λ is the operating laser wavelength of laser glass 1. After the processing is completed, it is cleaned. Acetone and isopropanol are used as cleaning fluids to clean th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com