Nylon 66 material and preparation method thereof

A nylon and PA66 technology, which is applied in the field of polymer materials, can solve the problems of easy flow, overflow and flash of PA66, and achieve the effect of accelerating the crystallization process, improving the flow and reducing the generation of flash.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

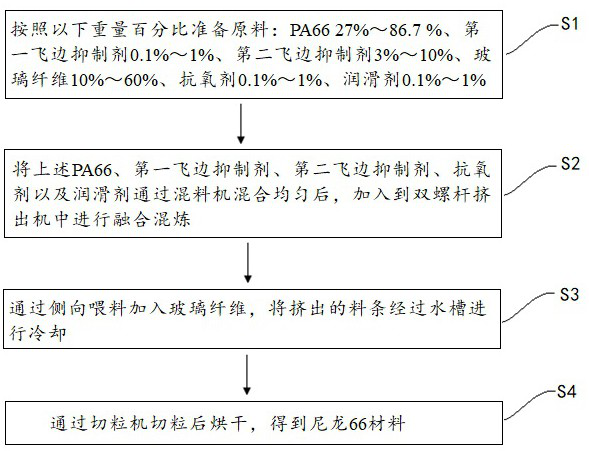

[0056] Corresponding to the above nylon 66 material, the embodiment of the present invention also provides a preparation method of nylon 66 material, refer to figure 1 As shown, the method includes the following steps:

[0057] S1: Prepare raw materials according to the following weight percentages:

[0058] PA66 27%~86.7%, the first flash inhibitor 0.1%~1%, the second flash inhibitor 3%~10%, glass fiber 10%~60%, antioxidant 0.1%~1%, lubricant 0.1%~1%;

[0059] S2: After mixing the above PA66, the first flash inhibitor, the second flash inhibitor, antioxidant and lubricant through the mixer, add them to the twin-screw extruder for fusion mixing;

[0060] S3: Add glass fiber through side feeding, and cool the extruded strip through a water tank, wherein the temperature of the cooling water is 15°C to 20°C;

[0061] S4: The nylon 66 material is obtained after pelletizing by a pelletizer, and the rotating speed of the pelletizer is 500rpm-700rpm.

[0062] All the above option...

Embodiment 1

[0095] A kind of nylon 66 material, calculated according to weight percentage, its component comprises:

[0096] PA66 66.4%, PA6T / 66 (second flash inhibitor) 3%, glass fiber 30%, antioxidant 0.3%, lubricant 0.3%, among which the relative sulfuric acid viscosity of PA66 is 2.4.

Embodiment 2

[0098] A kind of nylon 66 material, calculated according to weight percentage, its component comprises:

[0099] PA66 64.4%, PA6T / 66 (second flash inhibitor) 5%, glass fiber 30%, antioxidant 0.3%, lubricant 0.3%, among which the relative sulfuric acid viscosity of PA66 is 2.4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com