Low-temperature fast-curing epoxy structural adhesive and preparation method thereof

An epoxy structural adhesive, fast curing technology, applied in the field of structural adhesives, can solve the problems of long curing time, difficult to adapt to large-scale production, fast efficiency, etc., to achieve fast curing speed, excellent impact resistance and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

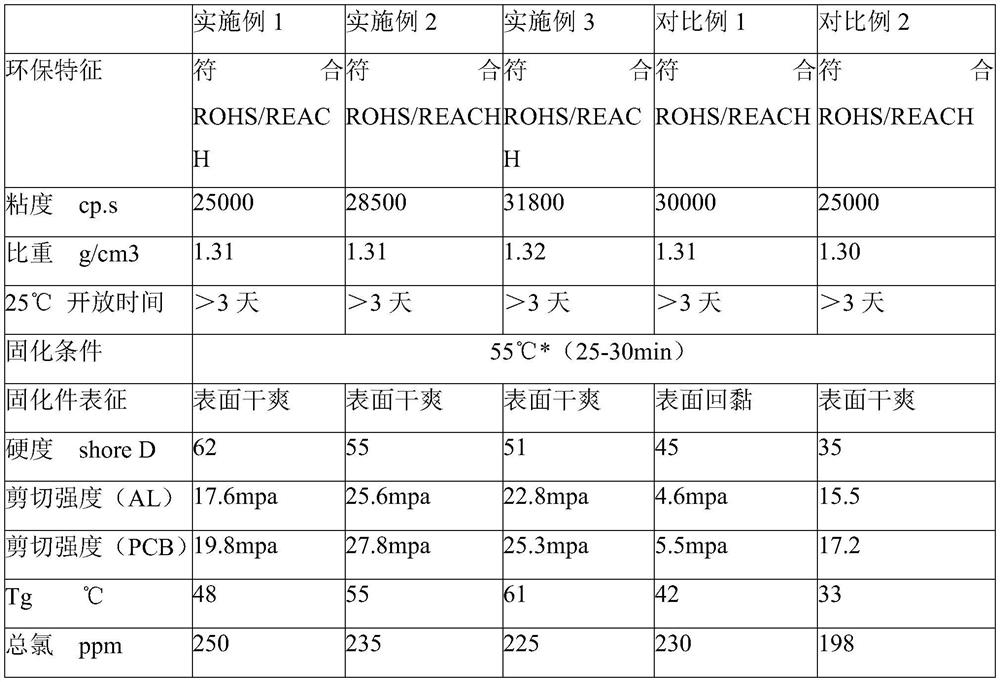

Examples

preparation example Construction

[0037] The preparation method of low-temperature fast-curing epoxy structural adhesive of the present invention comprises the following steps:

[0038] (1) Pass bisphenol F epoxy resin, secondary mercaptan, meteorological silica and silicon micropowder through a three-roll mill, adjust the distance between the front and rear rollers to 20 μm and 10 μm, and grind 3 to 5 times to obtain a grinding mixture (Visual inspection without uniform objects);

[0039] (2) Add the grinding mixture, plasticizer, latent curing agent and polymerization inhibitor into the planetary reactor, adjust the vacuum degree and temperature of the planetary reactor, stir until no bubbles are generated, let stand, and exhaust.

[0040] In addition, what needs to be added is: the vacuum degree of the planetary reactor is -0.11-0.09MPa, and the temperature is 15-20°C.

[0041] Before the bisphenol F epoxy resin passes through the three-roll mill, in order to avoid its crystallization in low temperature cl...

Embodiment 1

[0043] This embodiment provides a low-temperature fast-curing epoxy structural adhesive, and its raw material composition includes:

[0044] Bisphenol F epoxy resin 43%; (Jer YL983U, epoxy equivalent is 160g / mol)

[0045] Plasticizer 6%; (acetyl tri-n-butyl citrate)

[0046] Secondary mercaptan 18%; (Youyang tetrakis (3-mercaptobutyric acid) pentaerythritol ester)

[0047] Latent curing agent 8%; (PN23 of Ajinomoto)

[0048] Fumed silica 2%; (Degussa fumed silica AEROSIL 200)

[0049] Inhibitor 0.3%; (methyl hydroquinone (MHQ))

[0050] Silica powder 22.7%. (Silverbond925)

[0051] Its preparation method is:

[0052] (1) Pass the formula amount of Jer YL983U, Youyang tetrakis (3-mercaptobutyrate) pentaerythritol ester, Degussa fumed silica AEROSIL 200 and Silverbond925 through the three-roll mill, and adjust the distance between the front and rear rollers to be 20 μm and 10 microns, grind 3-5 times to obtain a grinding mixture (no inhomogeneity by visual inspection);

...

Embodiment 2

[0057] This embodiment provides a low-temperature fast-curing epoxy structural adhesive, and its raw material composition includes:

[0058] Bisphenol F epoxy resin 40.7%; (Jer YL983U, epoxy equivalent is 160g / mol)

[0059] Plasticizer 6%; (acetyl tri-n-butyl citrate)

[0060] Secondary mercaptan 18%; (Youyang tetrakis (3-mercaptobutyric acid) pentaerythritol ester)

[0061] 10% latent curing agent; (PN23 of Ajinomoto)

[0062] Fumed silica 2%; (Degussa fumed silica AEROSIL 200)

[0063] Inhibitor 0.3%; (methyl hydroquinone (MHQ))

[0064] Silica powder 23%. (Silverbond925)

[0065] The preparation process of embodiment 2 and embodiment 1 is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com