Biological fine desulfurization treatment system for biogas

A treatment system and fine desulfurization technology, which is applied in the field of biogas fine desulfurization treatment system, can solve the problems of high cost of desulfurization agent, dust in the replacement work, failure to meet the standard, etc., and achieve good purification effect and strong washing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

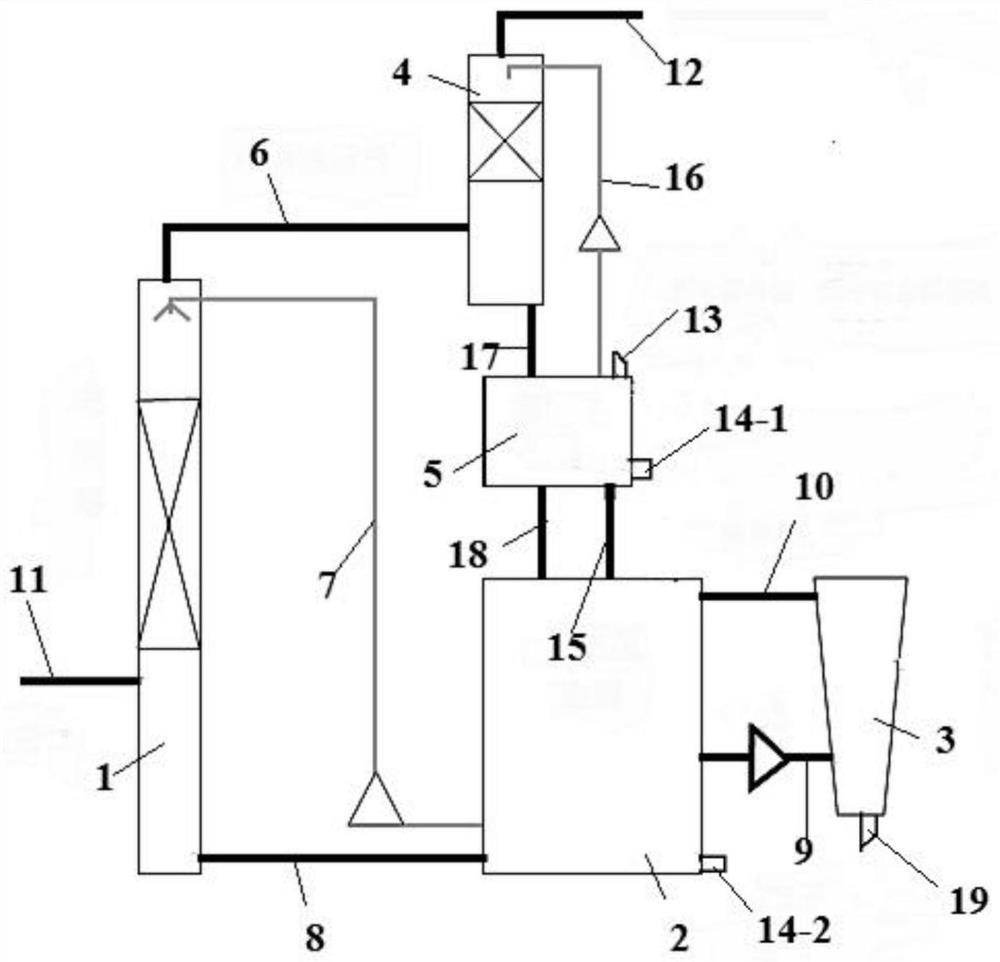

[0033] The embodiment of the present invention discloses a biogas desulfurization treatment system, and the adopted technical scheme is as follows:

[0034] A biological fine desulfurization treatment system for biogas, comprising a desulfurization scrubber 1, a regeneration reactor 2, and a sulfur precipitator 3, characterized in that it also includes: a refining scrubber 4 and a refining scrubber circulation tank 5;

[0035] The exhaust pipeline 6 of the desulfurization scrubber 1 is connected with the refining scrubber 4, the liquid inlet pipeline 7 of the desulfurization scrubber 1 is connected with the regeneration reactor 2, and the rich liquid discharge pipeline 8 of the desulfurization scrubber 1 is connected with the regeneration reactor 2 connected;

[0036] The sulfur discharge pipeline 9 of the regeneration reactor 2 is communicated with the sulfur precipitator 3, and the drain pipeline 10 of the sulfur precipitater is communicated with the regeneration reactor 2; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com