Composite device for zero correction and on-load test of guided missile steering engine

A technology of zero correction and compound device, which is applied in ammunition testing, ammunition, self-propelled ammunition, etc., can solve problems such as low debugging accuracy and complicated debugging process, and achieve simplified testing process, simple and fast replacement process, and reduced readings effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

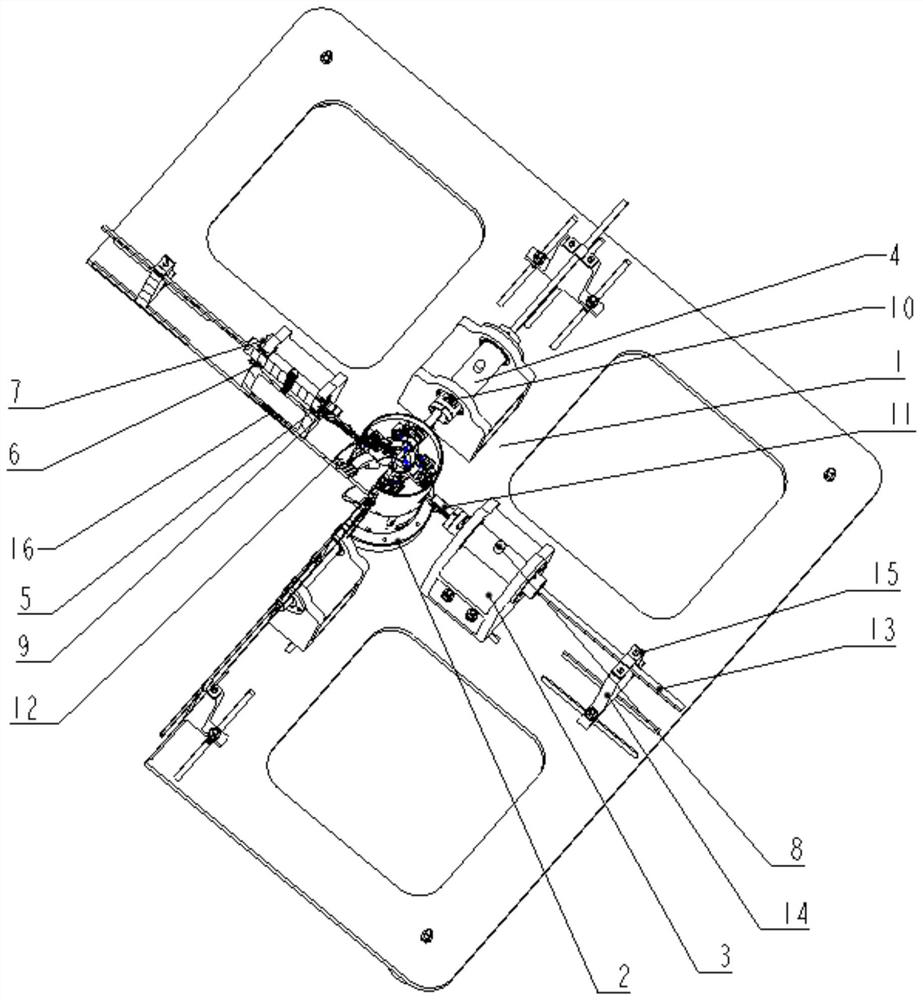

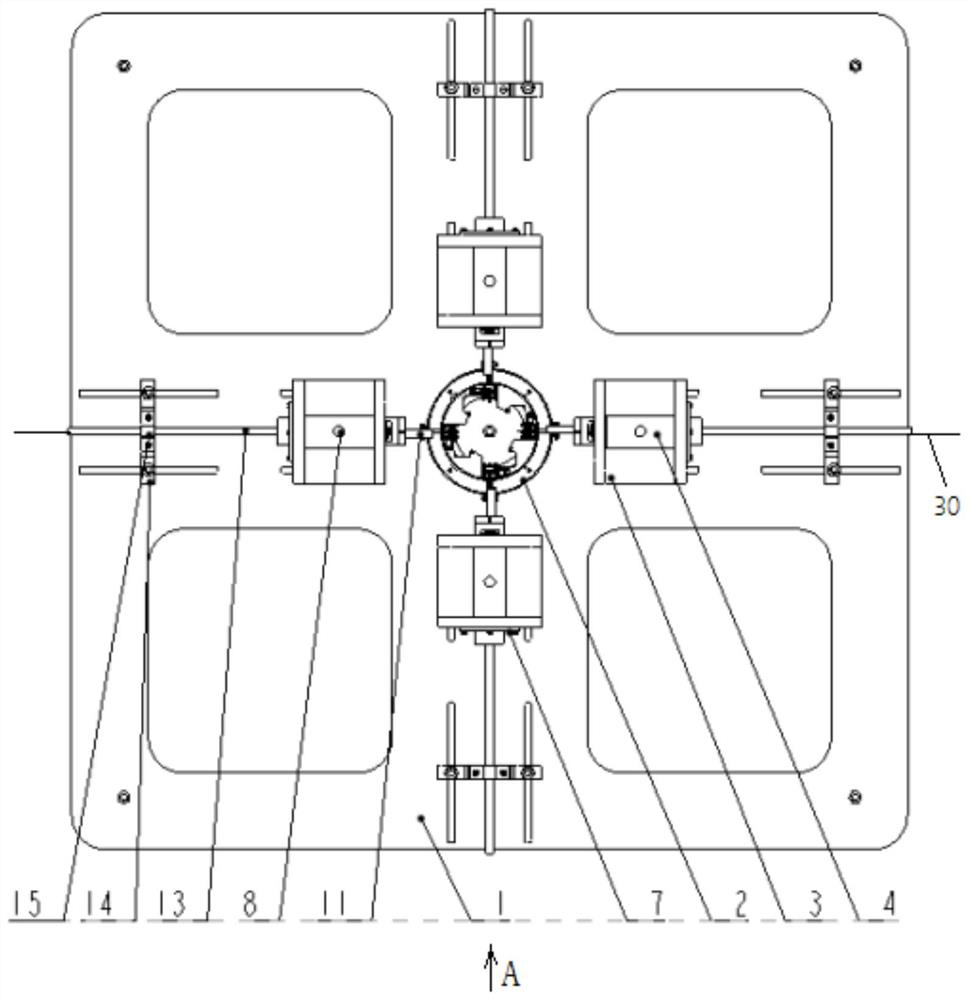

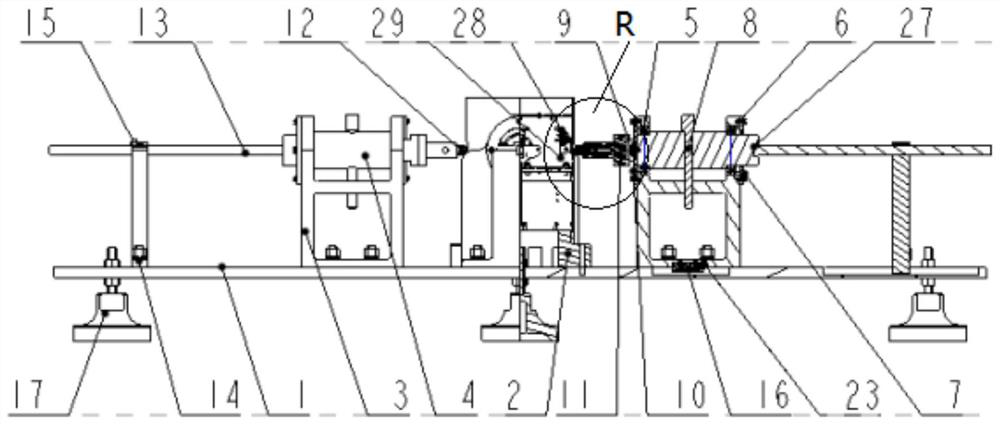

[0035] like Figure 1 to Figure 6 As shown, the present invention provides a composite device for zero correction and load testing of steering gear for missiles, including installation plane, steering gear base and four groups of zero adjustment and load testing components with the same structure, wherein,

[0036]The four groups of zero-adjustment and on-load test components with the same structure are evenly distributed in the circumferential direction on the installation plane; the zero-adjustment and on-load test components include a rudder turret with a rudder turret hole, a rotating shaft bracket, a rotating shaft, and a rotating shaft Mechanism, zero pin, angle sensor assembly, telescopic arm bracket, telescopic arm, torsion bar, torsion bar seat; the shaft bracket and the telescopic arm bracket are installed on the installation plane in a straight line, and are correspondingly arranged on the shaft Both the rotating shaft on the support and the telescopic arm arranged ...

Embodiment 2

[0043] like Figure 1 to Figure 6 As shown, the present invention provides a composite device for zero correction and load testing of steering gear for missiles, including installation plane, steering gear base and four groups of zero adjustment and load testing components with the same structure, wherein,

[0044] The four groups of zero-adjustment and on-load test components with the same structure are evenly distributed in the circumferential direction on the installation plane; the zero-adjustment and on-load test components include a rudder turret with a rudder turret hole, a rotating shaft bracket, a rotating shaft, and a rotating shaft Mechanism, zero pin, angle sensor assembly, telescopic arm bracket, telescopic arm, torsion bar, torsion bar seat; the shaft bracket and the telescopic arm bracket are installed on the installation plane in a straight line, and are correspondingly arranged on the shaft Both the rotating shaft on the support and the telescopic arm arranged...

Embodiment 3

[0054] like Figure 1 to Figure 6 As shown, the present invention provides a composite device for zero correction and load testing of steering gear for missiles, including installation plane, steering gear base and four groups of zero adjustment and load testing components with the same structure, wherein,

[0055] The four groups of zero-adjustment and on-load test components with the same structure are evenly distributed in the circumferential direction on the installation plane; the zero-adjustment and on-load test components include a rudder turret with a rudder turret hole, a rotating shaft bracket, a rotating shaft, and a rotating shaft Mechanism, zero pin, angle sensor assembly, telescopic arm bracket, telescopic arm, torsion bar, torsion bar seat; the shaft bracket and the telescopic arm bracket are installed on the installation plane in a straight line, and are correspondingly arranged on the shaft Both the rotating shaft on the support and the telescopic arm arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com