Photoresist stripping liquid and stripping process

A stripping solution and photoresist technology, applied in the field of electronic chemicals, can solve the problems of substrate surface residue, wire short circuit, affecting the yield of liquid crystal panel finished products, etc., to achieve the effect of improving yield, eliminating bulging and improving water washability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

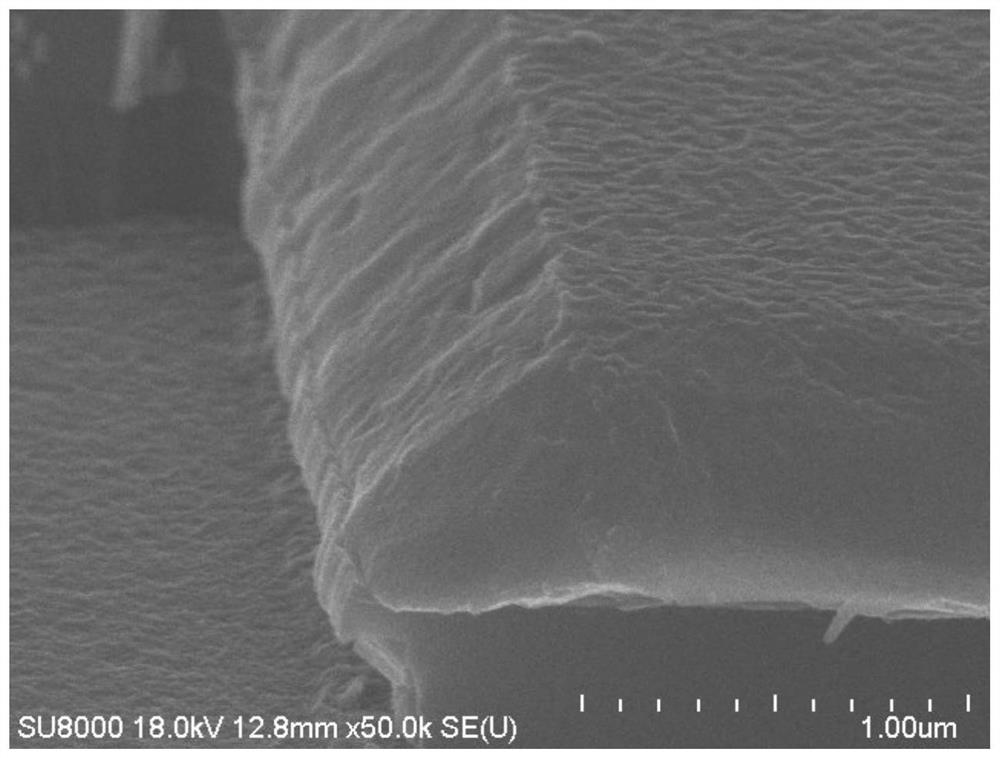

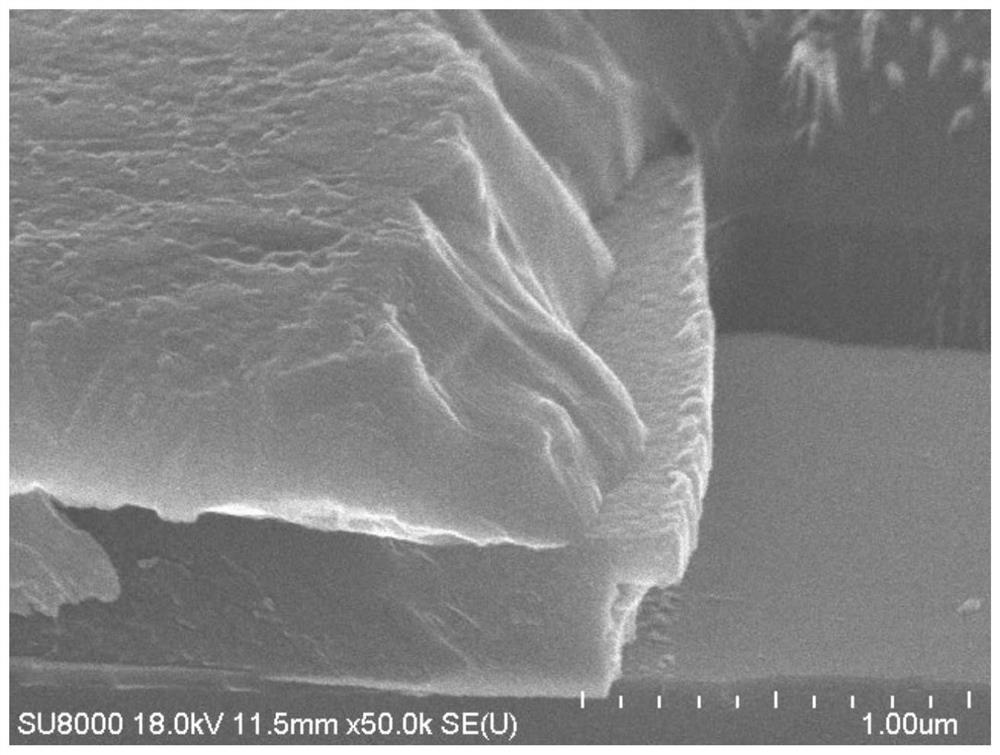

[0036] Preparation of sample substrate: sputter molybdenum-niobium layer on a 2.9m*3.3m glass substrate by vapor deposition and copper layer (thickness ), the photoresist is coated on the surface of the copper layer, the thickness of the photoresist is 1.5 μm, after exposure and wet etching in sequence, the photoresist on the surface of the substrate is peeled off with a stripping solution.

[0037] Photoresist stripping process of stripping liquid: spraying time 120s, substrate conveying speed of stripping unit: 4500mm / min; flow rate of stripping liquid 470L / min, stripping liquid process temperature 60°C;

[0038] Process parameters for substrate washing and air knife treatment after stripping: the substrate transfer speed is the same as that of the stripping unit; normal temperature water is used for cleaning, and the water flow rate is 210L / min; the air knife pressure is 0.065Mpa, and the liquid knife process is 110L / min.

Embodiment

[0039] Embodiment (abbreviated as S, the same below)

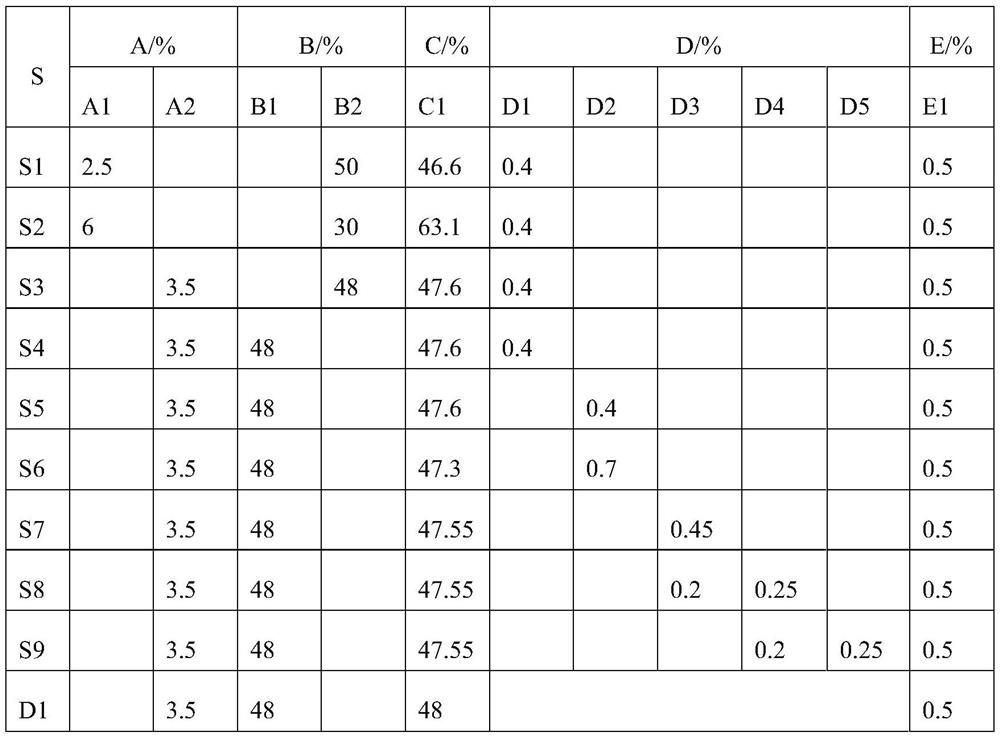

[0040] 1. The stripping solution of Examples 1-9 and Comparative Example (abbreviated as D, the same below) 1 is configured according to the formula in the following table, and mixed evenly; in the following table 1:

[0041] A-alcohol amine compounds, ethanolamine A1, isopropanolamine A2;

[0042] B-alcohol ether compounds, diethylene glycol monomethyl ether B1, diethylene glycol monobutyl ether B2;

[0043] C-organic solvent, N-methylpyrrolidone C1

[0044] D-oligomer additives, polyethylene glycol 400D1, polyethylene glycol monomethyl ether (molecular weight 380-420) D2, monocarboxyl-terminated polyethylene glycol (PEG molecular weight 600) D3, double carboxyl polyethylene glycol ( PEG molecular weight 600) D4, carboxyl-terminated polyethylene glycol monomethyl ether (polyethylene glycol monomethyl ether molecular weight 600) D5;

[0045] E-copper protective agent, benzotriazole E1;

[0046] Table 1

[0047]

Embodiment 4

[0065] The alcohol ether in the photoresist stripping solution in Example 4 is diethylene glycol monomethyl ether. During water washing and air knife treatment, the foaming performance is low, and the residue on the substrate is reduced. Compared with Example 3, the average value of defective points is reduced;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com