Multi-metal composite oxide coated modified lithium manganate positive electrode material and preparation method thereof

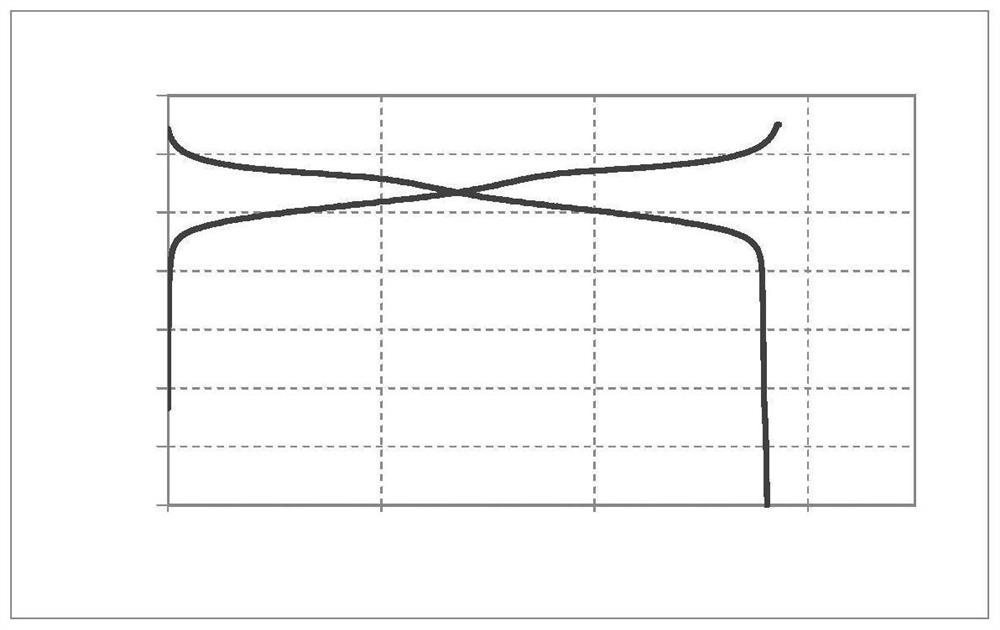

A technology of composite oxides and lithium manganate, applied in chemical instruments and methods, manganese compounds, inorganic chemistry, etc., can solve the problems of inability to have both capacity and cycle performance, high-temperature cycle performance cannot be effectively improved, and capacity drops rapidly, etc. problems, to achieve the effect of outstanding cycle performance, good protection, and improved capacity and energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

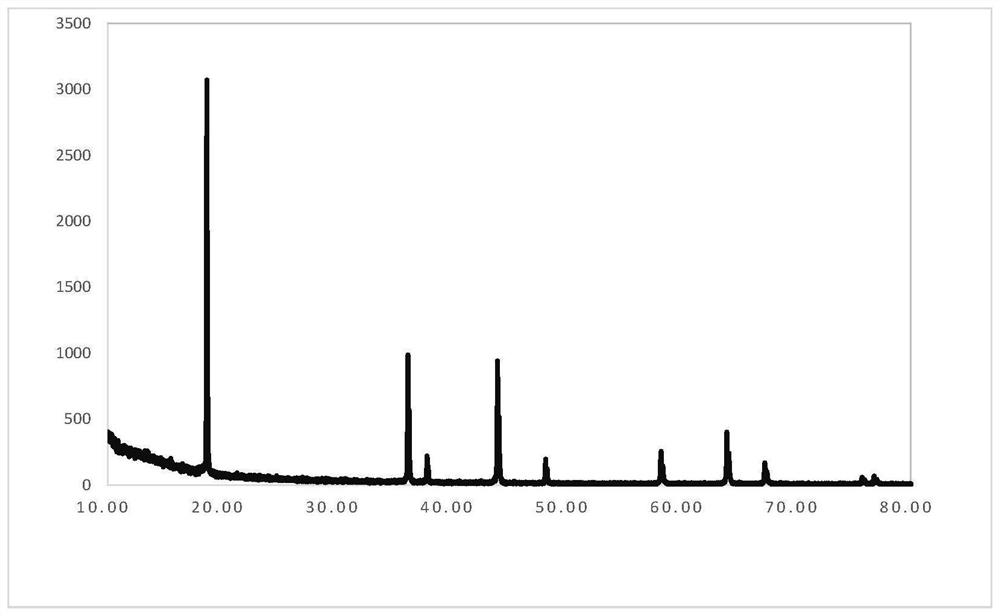

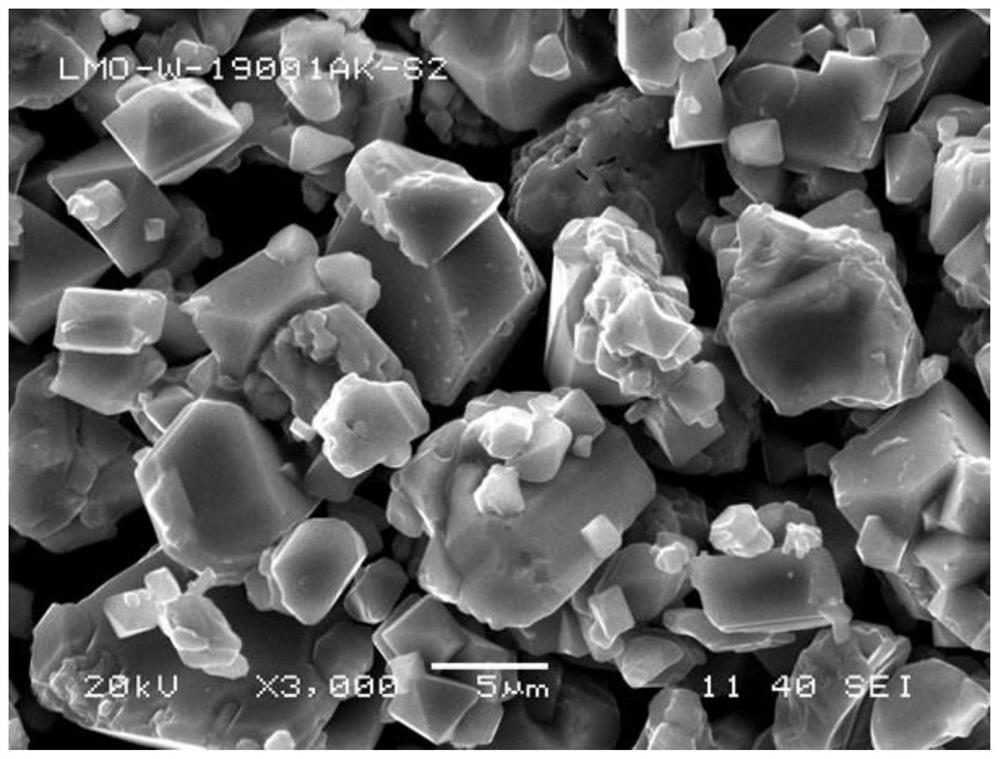

[0033] A kind of multi-metal composite oxide coating modified lithium manganate cathode material of the present invention is based on Li 1.075 mn1.845 Al 0.08 o 4 As the matrix, the surface of the matrix is coated with Li(Mn) 0.83 (Al) 0.027 o 2 cladding.

[0034] The preparation method of the modified lithium manganate cathode material of the present embodiment comprises the following steps:

[0035] (1) Press Li 1.075 mn 1.845 Al 0.08 o 4 Design ratio, after calculation, 10kg manganese source raw material MnO 2 , 2.37kg battery grade lithium carbonate, 371.8g dopant aluminum hydroxide, join in the high-speed mixer, 500rpm mixes 5min, then 1500rpm mixes 20min, after the mixing is completed, there is no white spot visually, and the mixture is obtained;

[0036] (2) Using a box-type atmosphere furnace, put the mixture obtained in step (1) into a sagger, loosely pack and level the surface of the mouth of the bowl and scrape it flat, put it into the sintering equipmen...

Embodiment 2

[0054] A kind of multi-metal composite oxide coating modified lithium manganate cathode material of the present invention is based on Li 1.075 mn 1.865 Mg 0.06 o 4 As the matrix, the surface of the matrix is coated with Li(Co) 0.55 (Al) 0.03 o 2 cladding.

[0055] The preparation method of the modified lithium manganate cathode material of the present embodiment comprises the following steps:

[0056] (1) Press Li 1.075 mn 1.865 Mg 0.06 o 4 Design ratio, after calculation, weigh 10kg manganese source raw material MnO 2 , battery grade lithium carbonate 2.34kg, dopant magnesia 142.5g, join in the high-speed mixer of mixing equipment, first mix 5min with 500rpm, then mix with 1500rpm for 20min, after the mixing is completed, there is no white spot visually, and the mixture is obtained ;

[0057] (2) heating the mixture after step (1) to 940° C., and sintering at a constant temperature for 12 hours;

[0058] (3) Roll the material after step (2), then use ACM crushi...

Embodiment 3

[0063] A kind of multi-metal composite oxide coating modified lithium manganate cathode material of the present invention is based on Li 1.045 mn 1.915 Ti 0.04 o 4 As the matrix, the surface of the matrix is coated with Li(Ni) 0.73 (Zr) 0.011 o 2 cladding.

[0064] The preparation method of the modified lithium manganate cathode material of the present embodiment comprises the following steps:

[0065] (1) Press Li 1.045 mn 1.915 Ti 0.04 o 4 Design ratio, calculated 10kg manganese source raw material MnO 2 , corresponding to 2.26kg of battery-grade lithium carbonate and 187.3g of dopant titanium oxide, cross-feeding is added to the high-speed mixer of the mixing equipment, first mixed at 500rpm for 5min, and then mixed at 1500rpm for 20min. After the mixing is completed, there is no white spot by visual inspection. got the mixture;

[0066] (2) The mixture after step (1) was sintered at a constant temperature of 930° C. for 12 hours, and cooled;

[0067] (3) Rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com