Metal middle frame, processing method of feed point surface of metal middle frame, shell assembly and electronic equipment

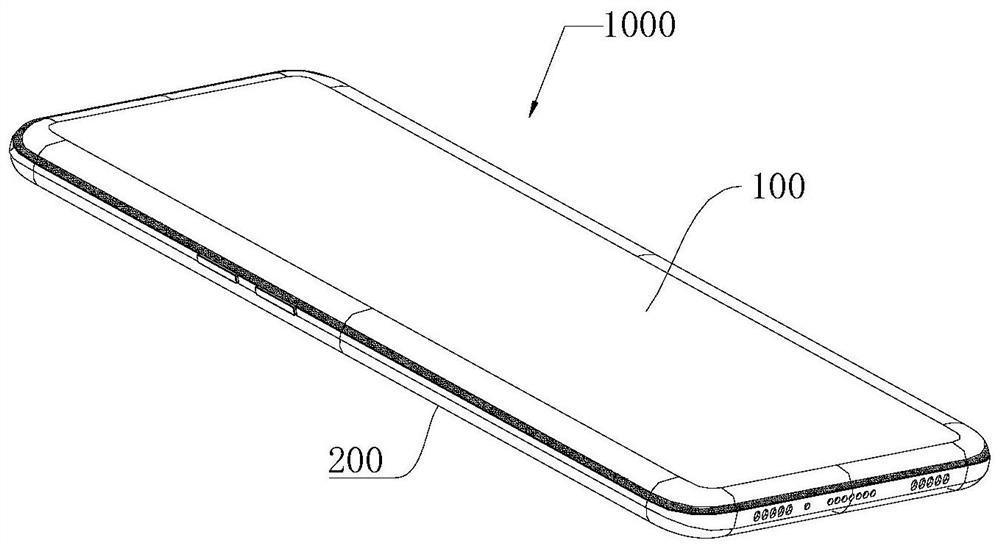

A metal middle frame and shell assembly technology, which is applied to antenna equipment with additional functions, antenna support/mounting device, antenna grounding switch structural connection, etc., can solve problems that affect the reliability of feed points and research needs to be further deepened

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

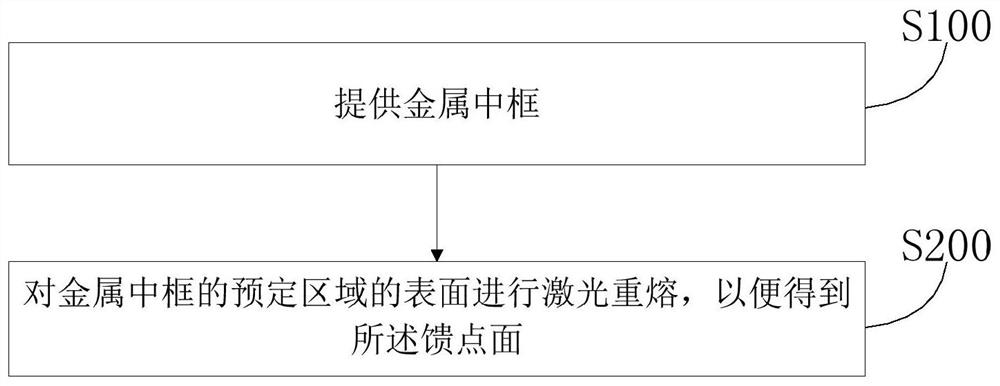

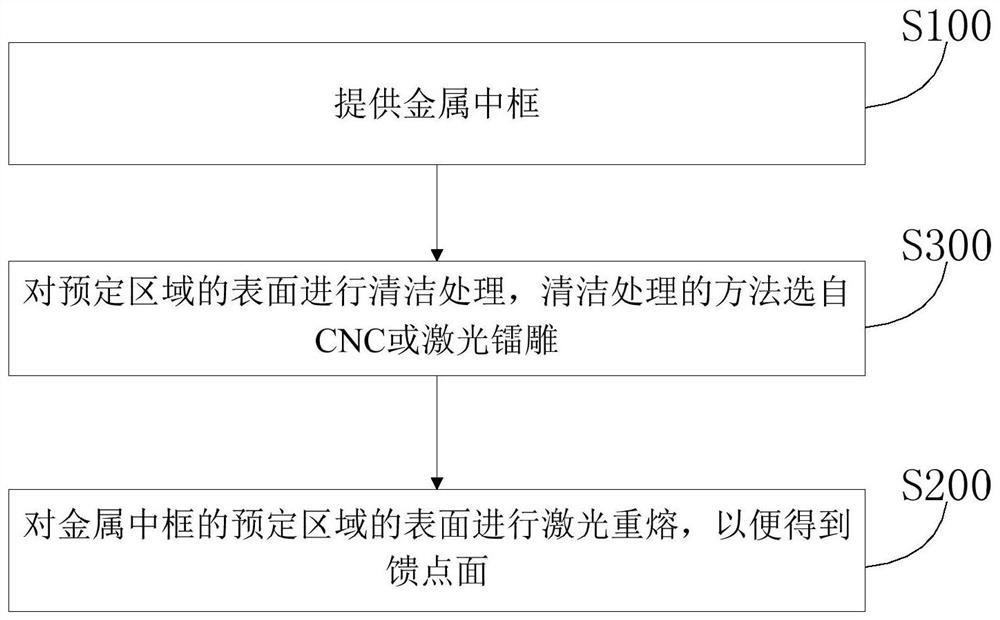

Method used

Image

Examples

Embodiment 1

[0042] Provide Al-10Si aluminum alloy middle frame;

[0043] Use the method of laser engraving to clean the predetermined area of the aluminum alloy middle frame to expose the metal surface of the middle frame;

[0044] Laser remelting treatment is carried out on the predetermined area of the Al-10Si aluminum alloy middle frame by using a pulsed laser, wherein the laser power of the pulsed laser is 75W; the scanning speed is 100mm / s; the Q pulse width is 30ns; the frequency is 4000kHz , to get the feed point surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface vickers hardness | aaaaa | aaaaa |

| Surface vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com