An industrial induction cooker core that takes into account circuit protection and efficient heating of the hob

A technology of induction cooker and hob, applied in the direction of induction heating, coil device, etc., can solve the problems of coil disk pollution, affect heating efficiency, burn out pots and other problems, achieve long service life of equipment, improve heating efficiency, and good protection effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

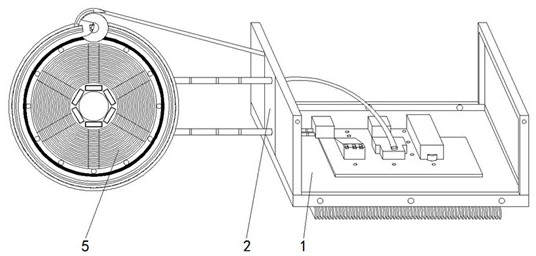

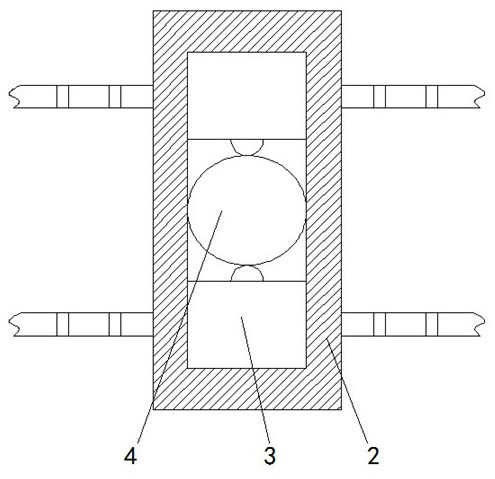

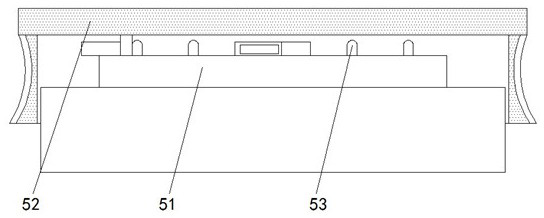

[0026] see Figure 1-Figure 6 , an industrial induction cooker core that takes into account both circuit protection and efficient heating of the hob, including a casing 1, a connector 2 is fixedly connected to the left side of the casing 1, a top bag 3 is fixedly connected to the inside of the connector 2, and a top bag 3 is fixedly connected to the inside of the connector 2 A switch 4 is fixedly connected to the inner wall, and a heating mechanism 5 is installed on the left side of the connector 2. The heating mechanism 5 includes a coil disk 51, which is inserted on the left side of the connector 2, and a microcrystalline Plate 52, the top of coil disk 51 is fixedly connected with guide rod 53, and guide rod 53 circumference is distributed on the top of coil disk 51, is used for guiding rubber strip 57 while limiting the displacement distance of microcrystalline plate 52, and the interior of coil disk 51 is opened Guide groove 54 is arranged, and the inwall of guide groove 5...

Embodiment 2

[0029] see Figure 7 , an industrial electromagnetic oven core that takes into account both circuit protection and efficient heating of the hob, including a casing 1, a connector 2 is fixedly connected to the left side of the casing 1, a heating mechanism 5 is installed on the left side of the connector 2, and a driving mechanism is also included 6. The driving mechanism 6 is installed inside the heating mechanism 5. The driving mechanism 6 includes a driving wheel 61. The inner wall of the driving wheel 61 is provided with ratchet grooves, and the driving wheel 61 is meshed with the tooth groove. The driving wheel 61 is fixedly connected to the winding wheel. 55, the inside of the driving wheel 61 is plugged with an inner wheel 62, and the inner wheel 62 is slidably connected to the inside of the guide groove 54, so that the inner wheel 62 will not follow the rotation of the driving wheel 61, and the driving wheel 61 can be limited by the pawl 65. Reversed, the inner wall of ...

Embodiment 3

[0032] see Figure 1-Figure 7, an industrial induction cooker core that takes into account both circuit protection and efficient heating of the hob, including a casing 1, a connector 2 is fixedly connected to the left side of the casing 1, a top bag 3 is fixedly connected to the inside of the connector 2, and a top bag 3 is fixedly connected to the inside of the connector 2 A switch 4 is fixedly connected to the inner wall, and a heating mechanism 5 is installed on the left side of the connector 2. The heating mechanism 5 includes a coil disk 51, which is inserted on the left side of the connector 2, and a microcrystalline Plate 52, the top of coil disk 51 is fixedly connected with guide rod 53, and guide rod 53 circumference is distributed on the top of coil disk 51, is used for guiding rubber strip 57 while limiting the displacement distance of microcrystalline plate 52, and the interior of coil disk 51 is opened Guide groove 54 is arranged, and the inwall of guide groove 54...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com