Steel-plastic composite pipe end flange welding system

A steel-plastic composite pipe and flange welding technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as welding obstruction, difficulty in dismantling tooling, and difficulty in ensuring welding quality, and achieve the effect of avoiding deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

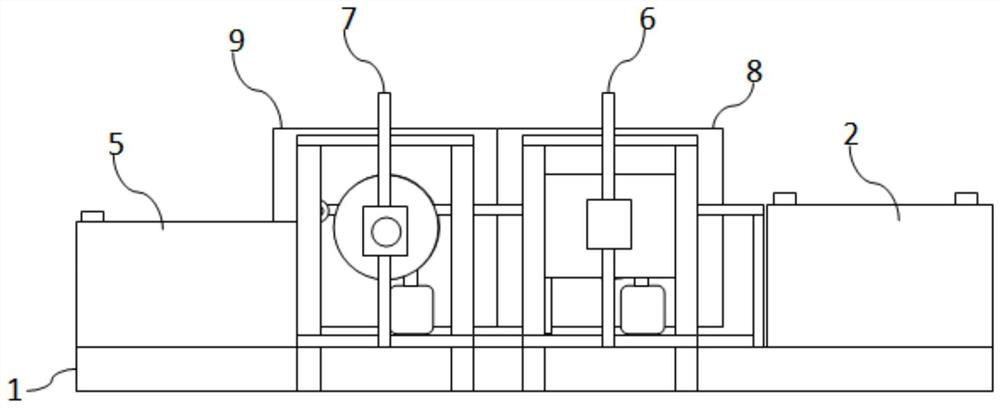

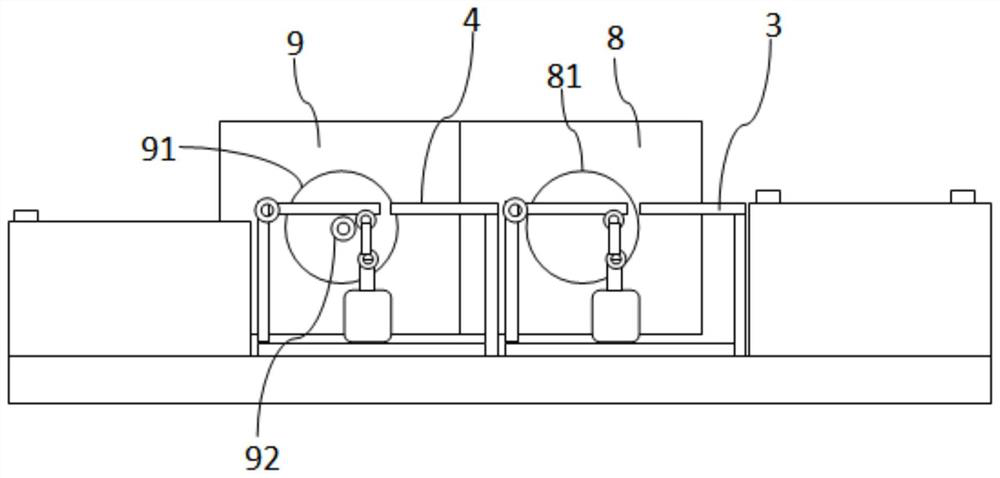

[0032] Such as Figure 1-8 As shown, a steel-plastic composite pipe end flange welding system includes a bottom frame 1, a feeding frame 2, a first fixed frame 3, a second fixed frame 4 and a temporary storage frame 5, and the bottom frame 1 is viewed from the right. To the left, a loading rack 2, a first fixing rack 3, a second fixing rack 4 and a temporary storage rack 5 are installed in sequence;

[0033] The top surface of the loading rack 2 is used for stacking steel pipes to be processed;

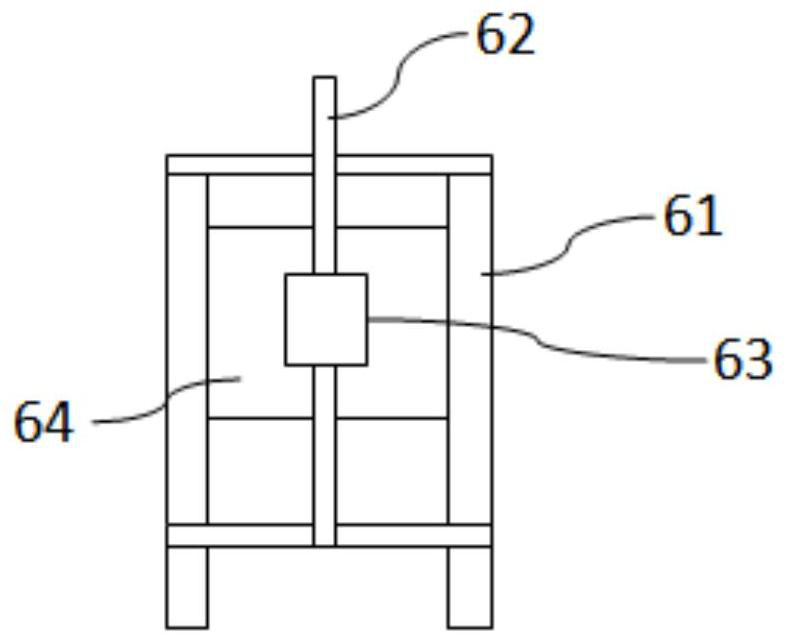

[0034] The first fixed frame 3 includes a frame A31, a first joint 32, a first connecting rod 33, a second joint 34, a second connecting rod 35, a third joint 36 and an air cylinder A37, wherein the first joint 32, the first connecting rod There are two sets of rod 33, second joint 34, second connecting rod 35, third joint 36 and cylinder A37, which are respectively arranged on the front and rear end surfaces of frame A31. There is a gap on the upper left side of frame A31, and the f...

Embodiment 2

[0045] The housing 93 of the welding auxiliary mechanism 9 is located above the turntable 91 and is provided with an upper cover 15. The front end of the upper cover 15 is vertically provided with several vertical bars 16. The lower end of the vertical bar 16 is connected with a mounting block 17, and the front end of the mounting block 17 is installed with The baffle C18, when in use, the position of the baffle C18 is adjusted to the top of the steel pipe to be processed, at least can not interfere with the rolling and transfer of the steel pipe. The function of the baffle plate C18 is to prevent the spattering range of sparks generated during welding from being too large, so as to improve production safety. Other structures of this embodiment are the same as those of Embodiment 1.

[0046] The above-described embodiments can be combined with each other.

[0047] Using method of the present invention (taking embodiment 1 as example):

[0048] 1) Use tools such as a crane or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com