Excircle fine super-grinding process method for precise micromotor bearing

A process method and micro-motor technology, applied in the field of bearing grinding, can solve the problems of high processing cost and substandard processing accuracy, and achieve the effects of reducing processing cost, low waste liquid generation rate, and improving processing environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The present invention proposes a process method for precision super-grinding of the outer circle of a precision micro-motor bearing, which includes the following steps:

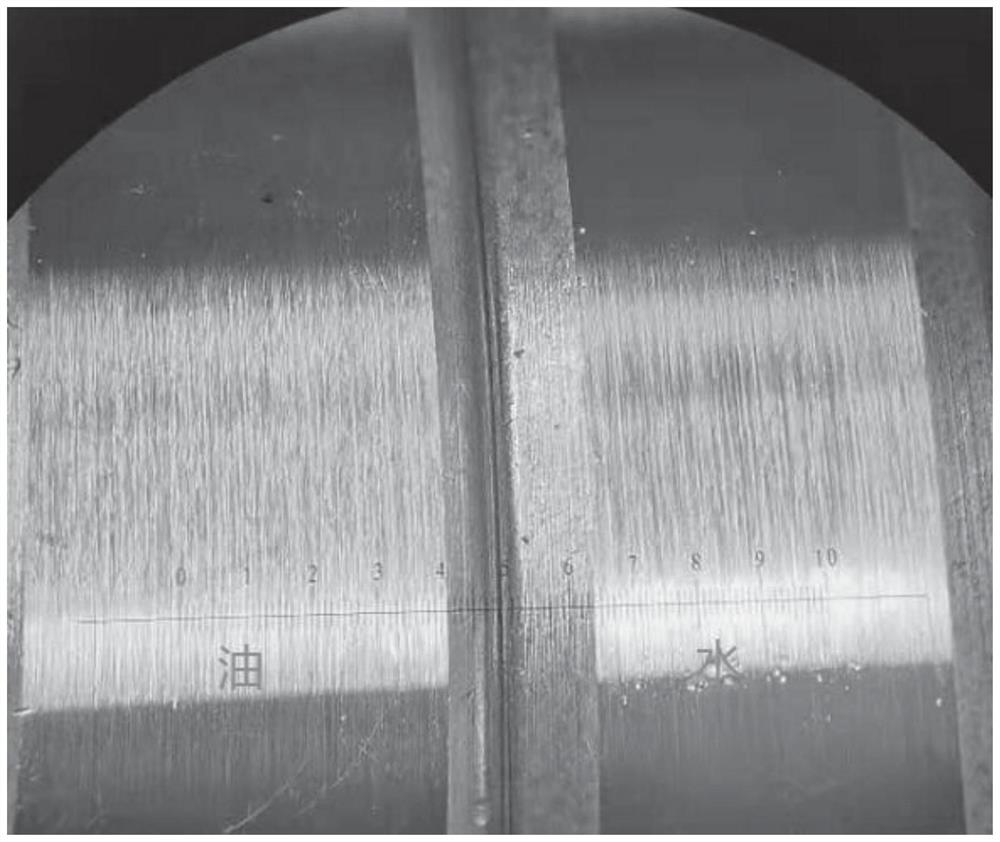

[0025] S1. Adding cutting fluid: add the diluted water-soluble cutting fluid to the circulating cooling box of the outer circle superfinishing machine, and start the circulating water-soluble cutting fluid of the outer circle superfinishing machine;

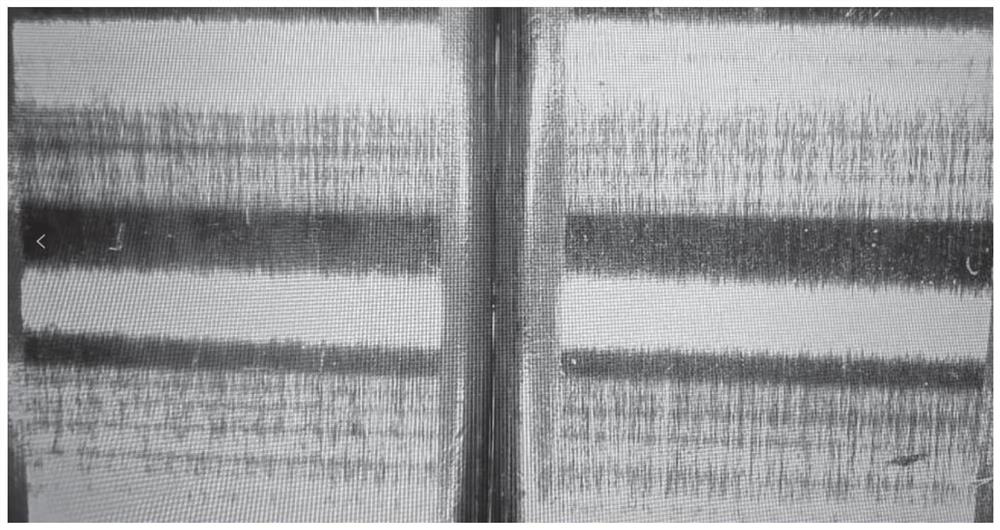

[0026] S2. Rough grinding: The tool holder of the outer circle superfinishing machine clamps rough oilstone with a mesh number of 800 mesh to 1500 mesh and a particle size of 25 to 30, and the guide wheel of the outer circle superfinishing machine drives the workpiece at a speed of 1800 to 2000rpm Rotate and operate the fixture frame so that the rough oil stone is pressed on the surface of the workpiece to reduce the outer circle size of the workpiece, and at the same time, the circulating cooling box discharges the water-soluble cutting fluid to wash the ...

Embodiment 2

[0043] The present invention proposes a process method for precision super-grinding of the outer circle of a precision micro-motor bearing, which includes the following steps:

[0044] S1. Adding cutting fluid: add the diluted water-soluble cutting fluid to the circulating cooling box of the outer circle superfinishing machine, and start the circulating water-soluble cutting fluid of the outer circle superfinishing machine;

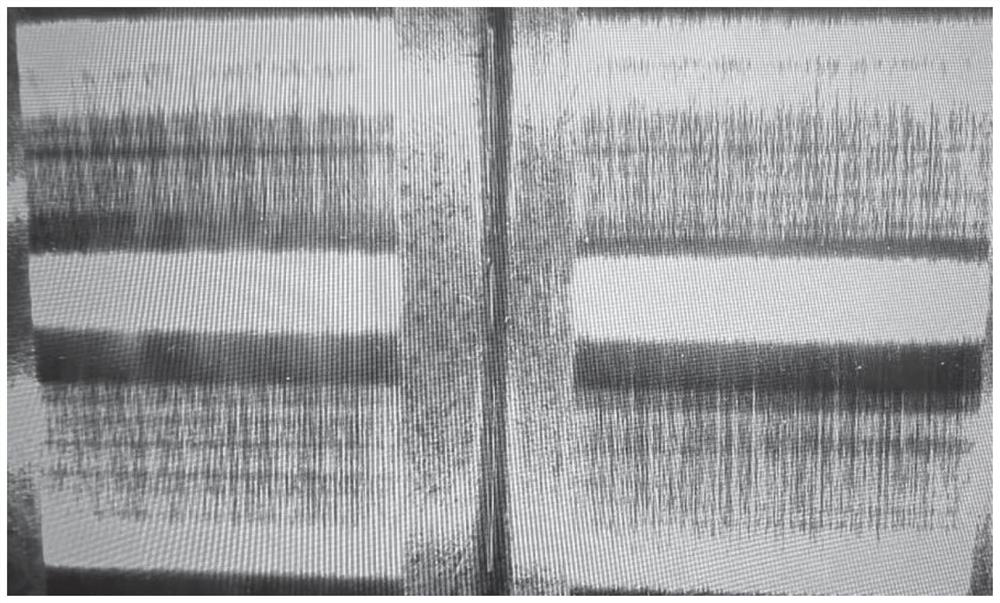

[0045] S2. Rough grinding: The tool holder of the outer circle superfinishing machine clamps the rough oilstone with a mesh number of 1000 mesh and a particle size of 28. The guide wheel of the outer circle superfinishing machine drives the workpiece to rotate at a speed of 1800rpm, and the operation of the fixture frame makes the coarse oil stone The oilstone is pressed on the surface of the workpiece with a pressure of 0.15-0.2MPa to reduce the outer circle size of the workpiece, and at the same time, the circulating cooling box discharges the water-solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com