Automatic hoisting and storing equipment for building material processing

A building material and hoisting technology, applied in the direction of lifting equipment braking device, hoisting device, transportation and packaging, etc., can solve the problem that the curved plate is prone to shaking and falling, save labor, ensure balance, Smooth and continuous transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

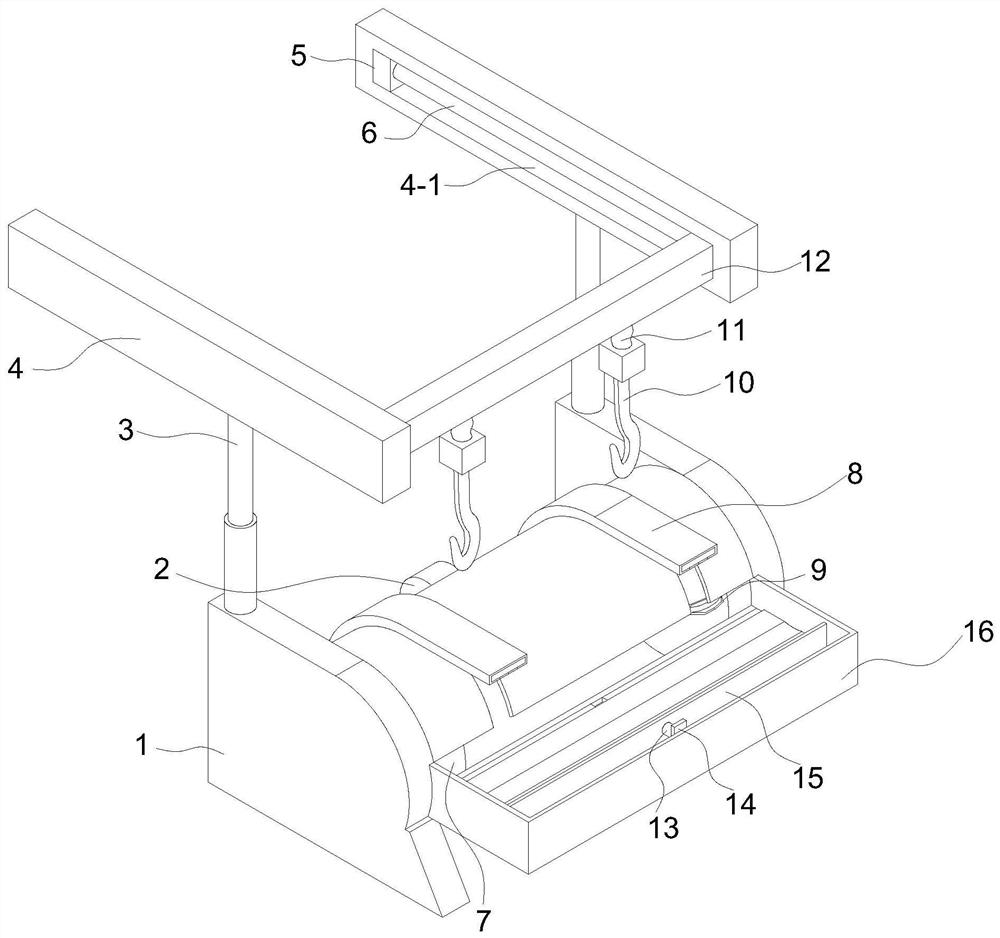

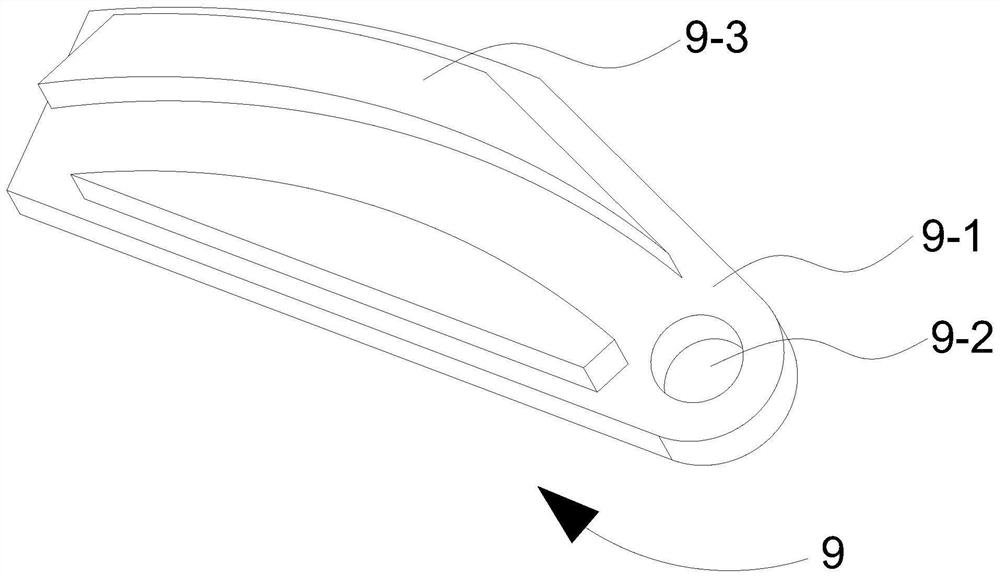

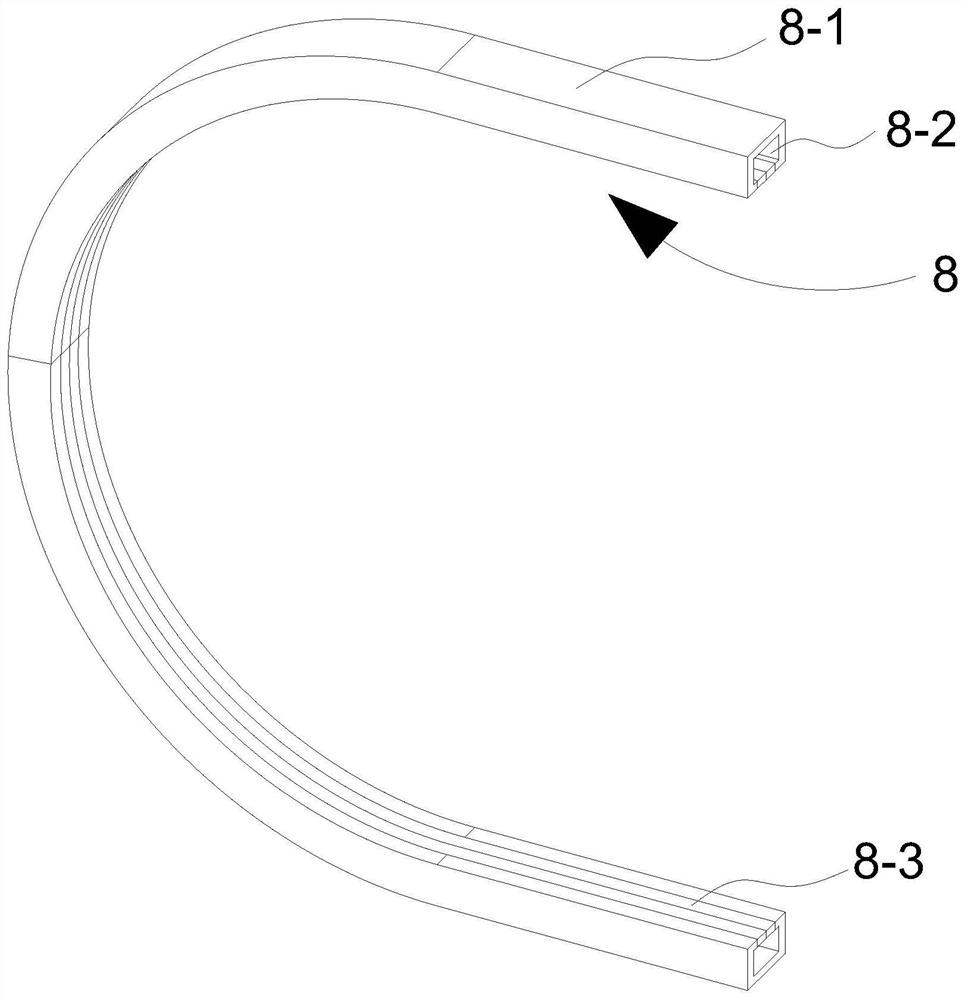

[0038] See Figure 1-6 A building material processing shown, it is capable of automatically lifting process arcuate plate secured storage device with automatic lifting, shaking and lifting process arcuate plate less likely to occur, a building material falling automated machining Lifting storage equipment. Specifically, processing and storage of building material lifting equipment automation, comprising a support plate, the clamping plate 7 and the clamp means 9.

[0039] The number is two support plates 1, 1 a close end to end surfaces of two support plates 19 is fixed is provided with a steering motor, the steering motor 19 controls a steering motor shaft 20, a steering motor shaft is provided with a clamping plate 7 is fixed on the 20 interposed the holding plate 7 defines a working chamber 7-1, 7-1 secured within the working chamber 21 is provided with a motor winding, the control winding 21 on the motor 22 has a winding shaft, the winding shaft is fixedly provided on the activ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com